Specific Process Knowledge/Etch/ICP Metal Etcher

Appearance

Etching of nanostructures in silicon using the ICP Metal Etcher

s

Two recipes have been optimized for the ASE. Their specification is on a 10 % etch load wafer with trenches.

- Shallolr: The shallow etch process will etch a 2 m opening down to make a 20 m trench.

- Deepetch: The deep etch process will etch a 50 m opening down to make a 300 m trench.

The standardization procedure on the ASE covers these two etches.

Recipes on the ASE

Shallolr

The shallolr recipe is designed to etch features (with sizes above 1 m) in silicon down to a depth that ranges from a few microns to some 50 microns. (If you need to etch deeper use Deepetch or more shallow, see Nanoetches.) It is specified to etch a 2 m wide trench down to a depth of 20 m on a wafer that has a global/local etch opening density of 10%.

The recipe is given below.

| Break | Gas | Cl2 20 sccm |

|---|---|---|

| Pressure | 2 mTorr, Strike 3 secs @ 5 mTorr | |

| Power | 600 W CP, 200 W PP | |

| Temperature | 20 degs | |

| Hardware | 100 mm Spacers | |

| Time | 15 secs | |

| Main | Gas | Cl2 20 sccm |

| Pressure | 2 mTorr, Strike 3 secs @ 5 mTorr | |

| Power | 600 W CP, 200 W PP | |

| Temperature | 20 degs | |

| Hardware | 100 mm Spacers | |

| Time | 15 secs |

The process runs for 31 cycles (5:56 mins). The fact that it's Bosch process is clear from the scallops on the sidewalls - one should be able to count 31 of them.

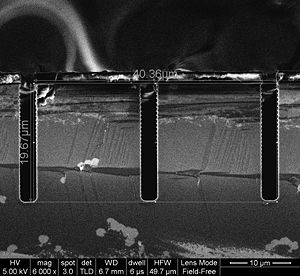

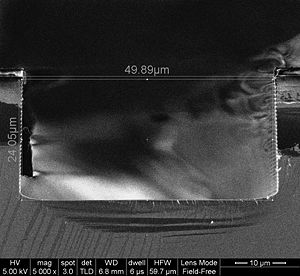

- Standardization images of the shallolr recipe

-

The profile of a 2 m trench

-

The profile of a 50 m trench