Specific Process Knowledge/Thin film deposition/Furnace LPCVD PolySilicon/Boron doped poly-Si

Results from the acceptance test 2012

Results from Tempress test January 2023

In January 2023 Tempress optimized the process for boron doped polysilicon again (they wanted to make some process development for a potential customer).

The depositions were done with 25 wafers in the furnace. Only 6" wafers were used.

The process parameters and the injector design that Tempress came up with will replace the old "DOPEPOLY" recipe from the acceptance test.

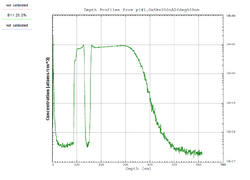

The results in table below are from run number 10.

| Recipe name | Temperature [C] (zone 1, 2, 3, 4, 5) | Gas flows [sccm] | Pressure [mTorr] | Deposition rate [nm/min] | Deposition rate - Uniformity over one wafer | Deposition rate - Uniformity over boat | Sheet resistance [Ohms/square] | Sheet resistance - Uniformity over one wafer | Sheet resistance - Uniformity over the boat |

|---|---|---|---|---|---|---|---|---|---|

| "POLYBOR" | 600, 596, 597, 600, 600 | SiH4 (through injector): 50

BCl3 (through injector): 2 |

150 | ~ 4.15 (6" wafers) | 2.9 % (door side)

1.3 % (pump side) |

0.5 % | 9.4 (door side)

10.01 (pump side) |

1.6 % (door side)

2.0 % (pump side) |

3.6 % |