Specific Process Knowledge/Etch/ICP Metal Etcher/Chromium/Cr etch data from AS

Appearance

Test data on Cr etch development by Anders Simonsen @NBI.KU

DOE experiments and results made on pattern free samples

| Name | Pressure [mTorr] | Coil power [W] | Platen power [W] | Total Flow (Cl2+O2) [sccm] | O2 % | Selectivity | Etch-rate [nm/min] | Side-angle | Corner | Resist-damage | Etch time [s] | Etch depth [nm] | Angle1 | Radius1 | Angle2 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| t5 | 5 | 300 | 25 | 40 | 25 | 0.21 | 49.03 | 25.5 | 319.5 | 1 | 175 | 57 | 28 | 331 | 23 | |

| t7 | 15 | 300 | 15 | 40 | 15 | 0.61 | 52.15 | 12 | 154.5 | 1 | 130 | 87 | 14 | 159 | 10 | |

| t8 | 5 | 500 | 15 | 40 | 25 | 0.4 | 49.50 | 39.5 | 228.5 | 1 | 120 | 101 | 42 | 169 | 37 | |

| t4 | 15 | 500 | 25 | 40 | 15 | 0.39 | 70.80 | 19.5 | 201 | 1 | 100 | 82 | 21 | 158 | 18 | |

| t2 | 5 | 300 | 25 | 80 | 15 | 0.21 | 40.54 | 40.5 | 262.5 | 3 | 185 | 75 | 42 | 274 | 39 | |

| t10 | 15 | 300 | 15 | 80 | 25 | 0.68 | 58.00 | 11.5 | 87 | 2 | 120 | 84 | 14 | 70 | 9 | |

| t6 | 5 | 500 | 15 | 80 | 15 | 0.43 | 49.24 | 29.5 | 300 | 5 | 145 | 81 | 29 | 362 | 30 | |

| t9 | 15 | 500 | 25 | 80 | 25 | 0.41 | 80.67 | 18.5 | 134.5 | 2 | 90 | 79 | 20 | 155 | 17 | |

| t1 | 10 | 400 | 20 | 60 | 20 | 0.35 | 63.13 | 17.5 | 288 | 2 | 115 | 79 | 20 | 292 | 15 | |

| t1R | 10 | 400 | 20 | 60 | 20 | 0.4 | 57.14 | 20 | 186 | 2 | 105 | 100 | 24 | 232 | 16 |

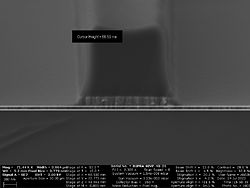

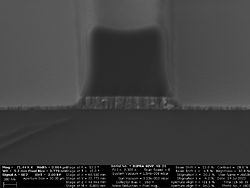

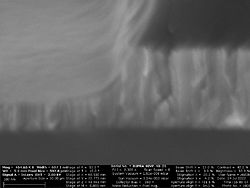

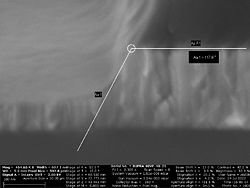

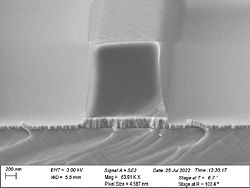

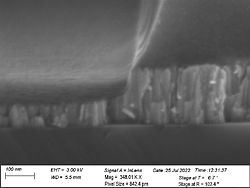

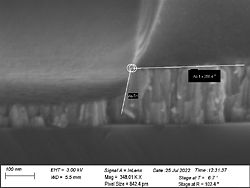

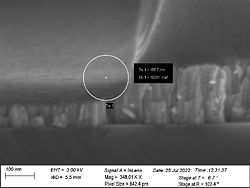

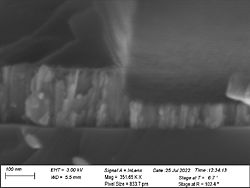

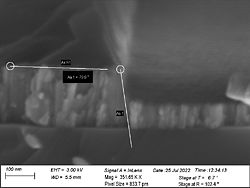

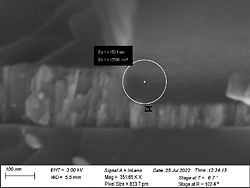

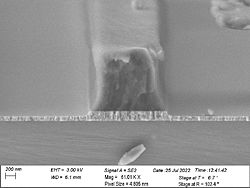

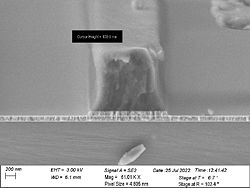

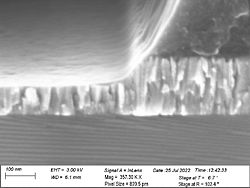

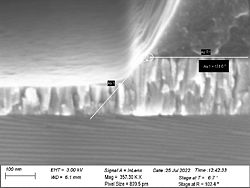

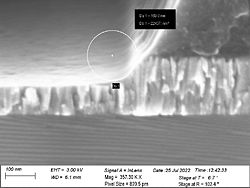

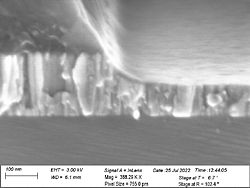

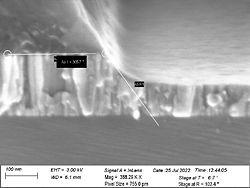

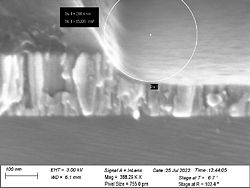

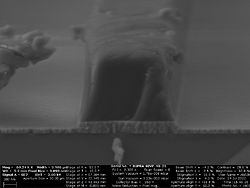

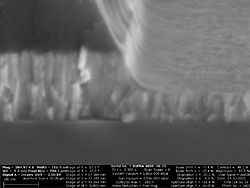

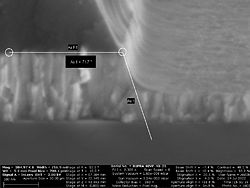

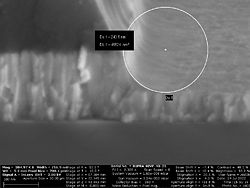

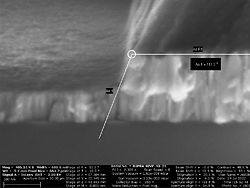

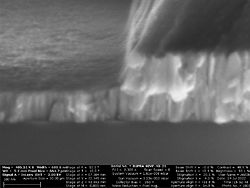

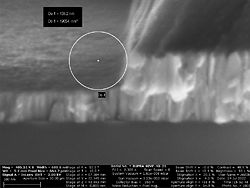

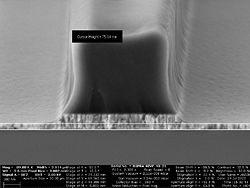

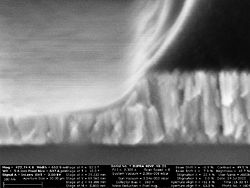

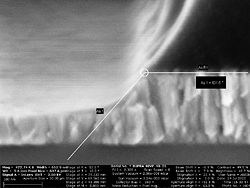

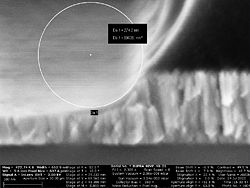

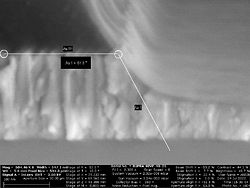

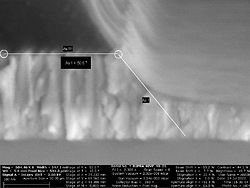

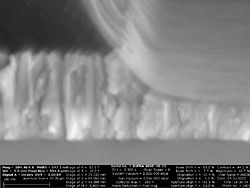

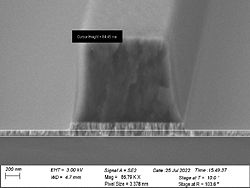

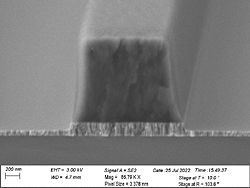

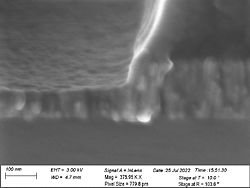

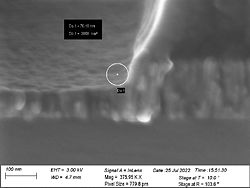

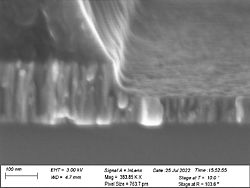

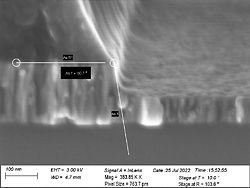

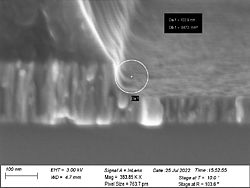

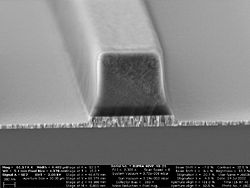

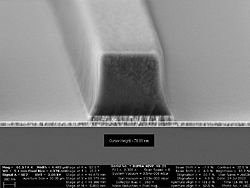

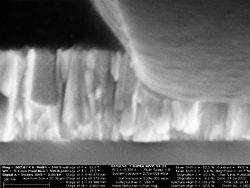

Sem images of the DOE

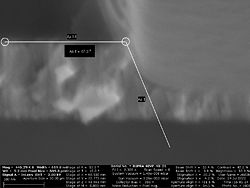

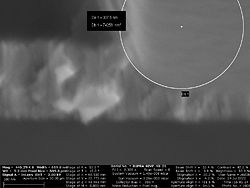

- Sample t5

- Sample t7

- Sample t8

- Sample t4

- Sample t2

- Sample t10

- Sample t1

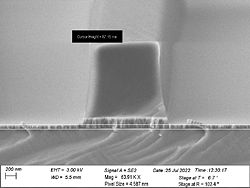

Tests made after DOE with e-beam patterned samples

| Recipe | Pressure [mTorr] | Coil power [W] | Platen power [W] | Total Flow Cl2+O2 [sccm] | O2% | Temp | Time [s] | CSAR etch rate [nm/min] | CSAR rate w bond | Etch rate [nm/min] | Selectivity | coil load | coil tune | plat load | plat tune | Comment | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| test11 | 15 | 300 | 15 | 40 | 25.00 | 20 | 23 | 80.87 | 73 | 52.17 | 0.65 | ||||||||

| test12 | 20 | 300 | 15 | 30 | 23.33 | 20 | 21 | 65.71 | 56 | 57.14 | 0.87 | ||||||||

| test13/laqs | 10 | 300 | 15 | 30 | 23.33 | 20 | 28 | 100.71 | 42.86 | 0.43 | Default recipe used for Cr etching when unspecified | ||||||||

| test14 | 10 | 300 | 15 | 40 | 25.00 | 20 | 30 | 88.00 | 40.00 | 0.45 | |||||||||

| nano | 5 | 500 | 15 | 60 | 0.17 | 10 | 33 | 99.00 | 36.36 | 0.37 | 41 | 52 | 31 | 50 | With strike pressure | ||||

| langman | 10 | 500 | 25 | 40 | 0.20 | 8 | 21 | 168.39 | 57.14 | 0.34 | 42 | 52 | 35 | 53 | With strike pressure |