Specific Process Knowledge/Characterization/Four-Point Probe

Feedback to this page: click here

Four-Point Probe

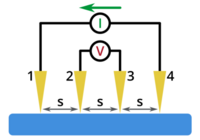

The set-up of the four point probe is four the tungsten carbide electrodes/probes.

The power source (DC) sends a current through the two outer electrodes. A digital voltage meter (DVM) measures the potential drop between the two inner electrodes.

There are two four point probes at Nanolab. Four point probe from Jandel is located inside the cleanroom(D-3) and Four-Point Probe from Veeco is now located in the basement(346-904).

Four-Point Probe from Jandel

The Four point probe is manufactured by Jandel Engineering Limited and using Jandel probe head and the RM3000+ Test Unit which can supply constant current between 10nA and 99.99mA, and measure voltage from 0.01mV to 1250mV.

For sheet resistance measurements, the quoted range is 1 milliohm/square to 5x108 ohms/square. Measurements outside this range are possible but with possible reduced accuracy. For volume (bulk) resistivity measurements, the quoted range is 1 milliohm.cm to 1x106 ohm.cm. Measurements outside of this range may be possible but will depend on sample type e.g. whether the sample is a thin layer.

Multiposition Probe stand can measure on wafers up to 200mm diameter. The Θ movement clicks in four positions at 90 degrees and the linear movement in up to 10 positions giving repeat placement accuracy of +/- 1mm.

Four-Point Probe from Veeco

The Four-Point Probe is a Veeco FPP-5000 for I/V measurement. The main purpose is to measure resistance and resistivity on a 4" silicon wafer. But can also be used to find thickness of thin layers or test if is a N- or P-type wafer.

It works only for 4" wafers because a special holder is need.

The user manual, technical information and contact information can be found in LabManager:

| Purpose | Resistance and resistivity measurement | |

|---|---|---|

| Process parameter range | Process Temperature |

|

| Process pressure |

| |

| Substrates | Batch size |

|

| Substrate material allowed |

|