LabAdviser/Technology Research/Nanoscale characterization of ultra-thin metal films for nanofabrication applications

Feedback to this page: click here

Nanoscale characterization of ultra-thin metal films for nanofabrication applications

- Project type: Ph.D. project

- Project responsible: Matteo Todeschini

- Supervisors: Jakob Birkedal Wagner, Flemming Jensen, Anpan Han

- Partners involved: DTU Danchip/Cen

Nanoscale characterization of ultra-thin metal films for nanofabrication applications

- Project type: Ph.D. project

- Project responsible: Matteo Todeschini (DTU Orbit)

- Supervisors: Prof. Jakob Birkedal Wagner, Assoc. Prof. Flemming Jensen, Assist. Prof. Anpan Han

- Partners involved: DTU Danchip/Cen

- Full thesis: Link

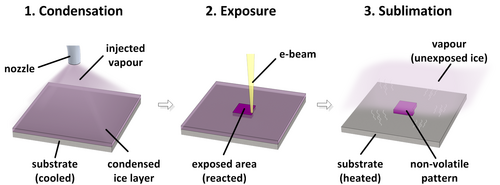

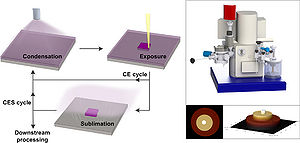

- Overview: Electron-Beam Lithography on Organic Ice Resists

- Overview: SEM-LEO Customizations for Organic Ice Resists

Project Description

The deposition of metal thin-film structures on dielectric or semiconductor substrates is central for the fabrication of structures and devices having nanoscale characteristic dimension. With the constant miniaturization of the devices and the fabrication of increasingly complex multi-material structures, the interaction between different ultra-thin layers has gained considerable importance in the field of thin-film science and technology in recent years. Therefore the characterization of such interactions in a wide range of temperatures and the description of their impact on the chemical composition, morphology and distribution of crystallographic orientations of multilayer thin-films is of utmost importance.

This PhD project focuses on the description of the interaction at the nanoscale level between noble metal films, widely used in different areas of micro- and nanofabrication, and extremely thin films of reactive transition metals, used to enhance adhesion onto the substrate - and thus referred as "adhesion layers". In particular, the work focused on the study of pure Au films and Cr/Au and Ti/Au systems, which were analyzed at different temperatures using a spectrum of complementary characterization techniques.

The project involved the introduction of the recently developed transmission Kikuchi diffraction (TKD) technique for the characterization of the crystal structure, grain size, and crystallographic texture of polycrystalline thin films. The remarkable potential of TKD for the in-situ analysis of thin films at elevated temperatures was revealed through the in-situ investigation of solid-state dewetting of Au, enabling to observe the start of the dewetting at a temperature as low as 150°C and demonstrating the crucial role of temperature in the modification of the nanostructure of metal thin films during nanofabrication. The data acquired during solid state dewetting were used to qualitatively study the formation and expansion of the holes in the film. A new criterion for the detection of the temperature of formation of the holes in the film was introduced and an in-situ monitoring of the formation and expansion of the holes in the Au film was also performed. This allowed to observe the formation of the holes exclusively in the positions of high surface energy grains and the reduction of the interface energy of the system by the elimination of grain boundaries and by grain coalescence.

The influence that Ti and Cr adhesion layers have on the microscopic and macroscopic properties of Au ultra-thin metal films was investigated at room temperature, with the analysis carried out on both bilayer and multilayer systems in order to obtain a more complete view of the interaction. The obtained results led to the formulation of a revised adhesion model for the Ti/Au and Cr/Au bilayer systems, which gives a description of the adhesion layer-overlayer interaction and can be used by the research community as guide-lines for adhesion layer and thin-film stack engineering. The model was also accompanied by the formulation of recommendations about the use of adhesion layers for different nanofabrication applications. The analysis of Ti/Au/Ti and Cr/Au/Cr multilayer systems allowed to obtain experimental evidence of the type of chemical bonding that leads to the increase of adhesion.

Dissemination

Publications in Peer Reviewed Journals

- Organic Ice Resists

- Link to Article

- W. Tiddi, A. Elsukova, H. T. Le, P. Liu, M. Beleggia, and A. Han

Nano Letters, vol. 17, pp. 7886-7891, 2017.

- Organic ice resists for 3D electron-beam processing - Instrumentation and operation

- Link to Article

- W. Tiddi, A. Elsukova, M. Beleggia, and A. Han

Microelectronic Engineering, vol. 192, pp. 38-43, 2018.

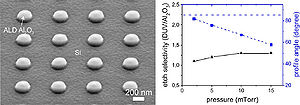

- Inductively coupled plasma nanoetching of atomic layer deposition alumina

- Link to Article

- A. Han, B. Chang, M. Todeschini, H. T. Le, W. Tiddi and M. Keil

Microelectronic Engineering, vol. 193, pp. 28-33, 2018.

Published Patents

- A METHOD FOR CREATING STRUCTURES OR DEVICES USING AN ORGANIC ICE RESIST.

- Link to Patent Database

- A. Han (Inventor), W. Tiddi (Inventor), M. Beleggia (Inventor)

IPC No.: B29C 67/ 00 A I. Patent No.: WO2017191079. Nov 09, 2017.

Conferences and Workshops Contributions

- Organic ice resists - condensed small molecules as spin-free volatile E-beam resists

- W. Tiddi, A. Elsukova, H. T. Le, M. Beleggia, and A. Han

Oral presentation at 43rd International conference on Micro and Nano Engineering, Braga, Portugal, 2017.

- Ice lithography - ice-based nanopatterning

- W. Tiddi

Workshop lecture at Nordic Nanolab User Meeting 2017, Trondheim, Norway, 2017.

- Advances in Ice Lithography in Denmark and China

- W. Tiddi, D. Zhao, M. Qiu, M. Beleggia, and A. Han

Abstract and Poster at 42nd International conference on Micro and Nano Engineering, Vienna, Austria, 2016.

- Ice lithography - water-based nanopatterning.

- W. Tiddi, M. Beleggia, and A. Han

Abstract and Poster at Sustain-ATV Conference 2016, Kgs. Lyngby, Denmark, 2016.

- Proximity Effects in a Chemically Amplified Electron Beam Resist Patterned at 100 keV.

- W. Tiddi, T. Greibe, M. Beleggia, and A. Han

Abstract and Poster at 41st International conference on Micro and Nano Engineering, The Hague, Netherlands, 2015.