Specific Process Knowledge/Etch/III-V ICP/InP-InGaAsP-InGaAs

Appearance

Feedback to this page: click here

InP/InGaAsP/InGaAs etch

Unselective etch for large sized features and small aspect ratios by David Larsson, DTU Photonics, 2011

| Recipe | InP Etch 1/InP Precond 1 |

| Cl2 flow | 20 sccm |

| N2 flow | 40 sccm |

| Ar flow | 10 sccm |

| Platen power | 100 W |

| Coil power | 500 W |

| Pressure | 2 mTorr |

| Platen chiller temperature | 180 oC |

| Comment | Use SiO2 carrier (not Si) (Kabi/Bghe June 2018) |

| Results (InP Etch 1) | |

| Etch rate | 500-600 nm/min |

| Sidewall angle | 86-87 o |

| Selectivity (InP:SiO2, InP:HSQ) | 50:1 |

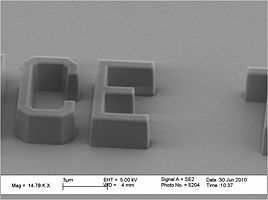

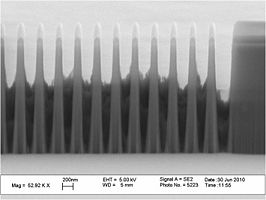

- Result of InP etching. David Larsson, DTU Photonics, 2011

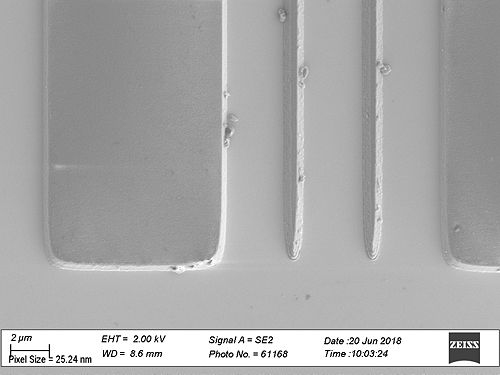

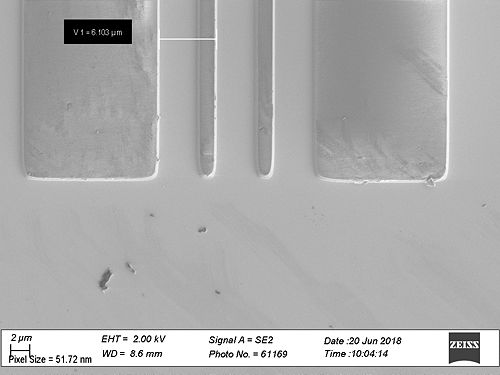

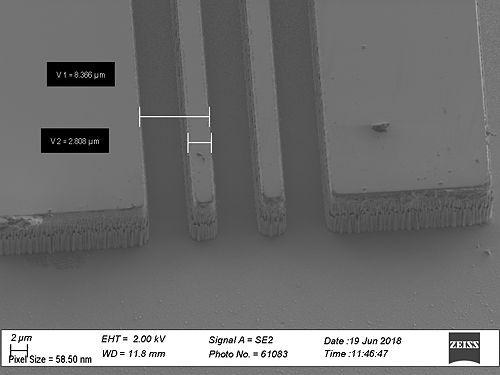

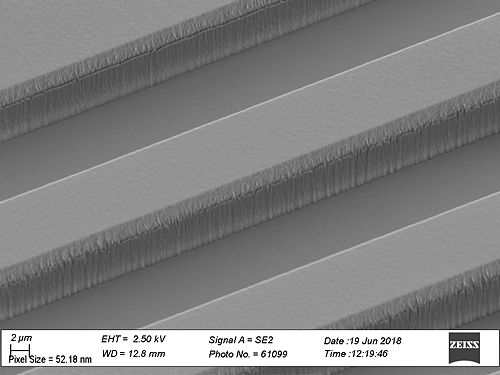

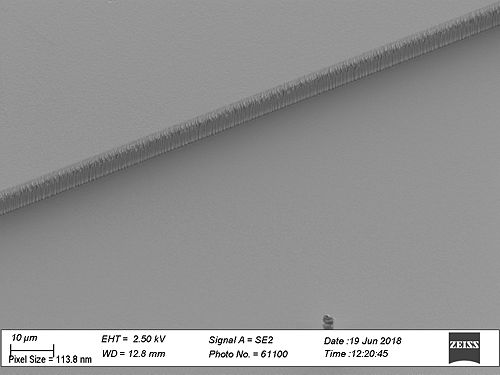

InP etching June 2018

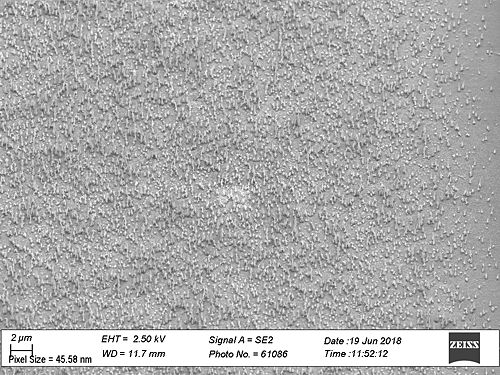

Sample pattern before etching

- Result of InP etching.

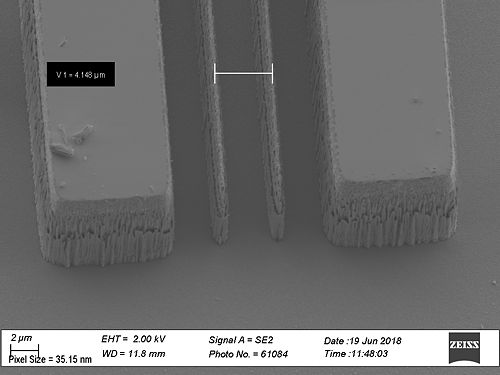

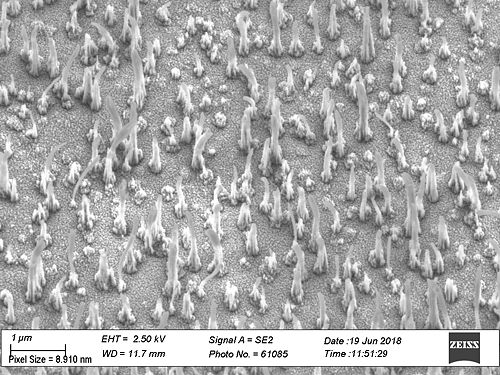

Etching of an InP piece on Si carrier

InP piece patterned with SiO2. The piece was etched on top of a Si wafer without bonding. The recipe "InP etch" was used. The roughness looks high in the bottom of the etched areas, especially in the large open areas.

- Result of InP etching.

-

low roughness in narrow trenched

-

low roughness in narrow trenched

-

A little higher roughnedd is larger trences

-

Much larger roughness in open areas

-

Zoom in on the large roughness

-

closed look at the large roughness in the open areas.

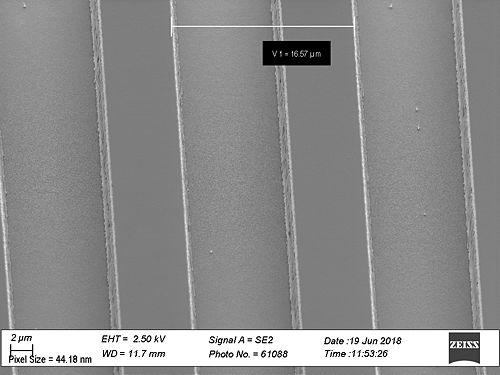

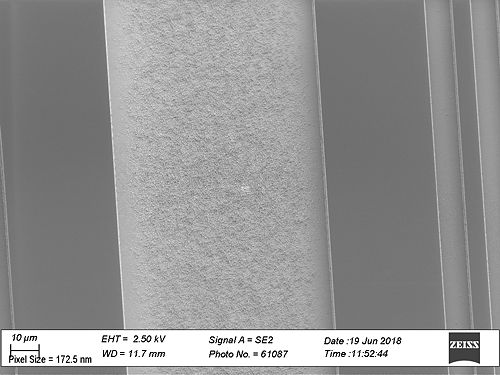

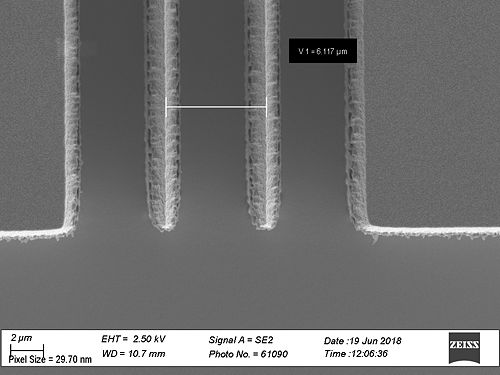

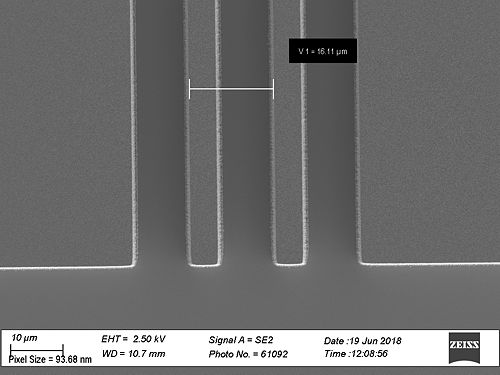

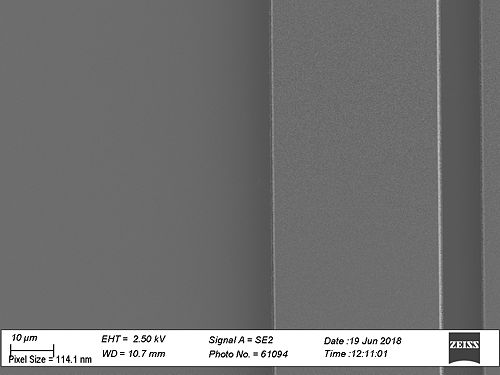

Etching of an InP piece on SiO2 carrier

InP piece patterned with SiO2. The piece was etched on top of a Si wafer coated with SiO2 without bonding. The recipe "InP etch" was used. The roughness looks low in the bottom of the etched areas, even in the large open areas.

- Result of InP etching.

-

Top view: oxide is gone on the narrow lines, low roughness in the trenches.

-

Top view: low roughness in the trenches.

-

30 dg view: low roughness in the trenches

-

30 dg view: low roughness in the trenches

-

Top view: low roughness in trench and in the large area