Specific Process Knowledge/Thin film deposition/ALD2 (PEALD)/TiO2 deposition using ALD2

Appearance

Feedback to this page: click here

Result from acceptance test

TiO2 deposition at 150 C (amorphous TiO2) using TiCl4 and H2O precursors

The test was done with 500 cycles where the growth rate was measured to be 0.0385 nm/cycle.

| TiCl4 | H2O | |

|---|---|---|

| Nitrogen flow | 150 sccm | 200 sccm |

| Pulse time | 0.1 s | 0.1 s |

| Purge time | 3.0 s | 4.0 s |

-

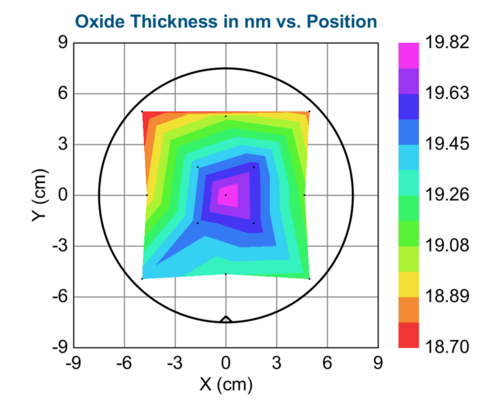

Uniformity profile across 150 mm Si wafer based on 13 measurement points measured with ellipsometer. The values for the grown oxide thickness can be seen in the table below.

| Parameter | Average | Min. | Max. | Std.Dev | %Range |

|---|---|---|---|---|---|

| Thickness (nm) | 19.27 | 18.70 | 19.82 | 0.34 | 5.7947 |

-

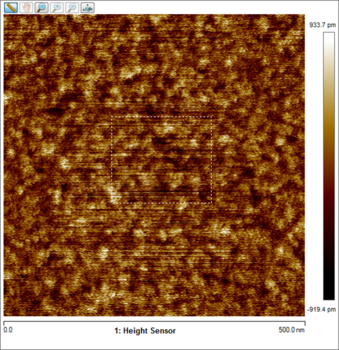

AFM measurement roughness 0.209 nm.

Pernille Voss Larsen, Mikkel Dysseholm Mar and Tanja Amport, DTU Danchip, 2016-2017.

TiO2 deposition at 300 C (anastase TiO2) using TiCl4 and H2O precursors

The test was done with 500 cycles there the growth rate was measured to be 0.0409 nm/cycle.

| TiCl4 | H2O | |

|---|---|---|

| Nitrogen flow | 150 sccm | 200 sccm |

| Pulse time | 0.1 s | 0.1 s |

| Purge time | 3.0 s | 4.0 s |

-

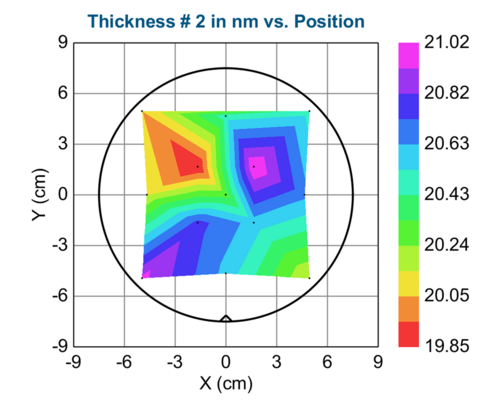

Uniformity profile across 150 mm Si wafer based on 13 measurement points measured with ellipsometer. The measured oxide thickness is also shown in the table below.

| Parameter | Average | Min. | Max. | Std.Dev | %Range |

|---|---|---|---|---|---|

| Thickness (nm) | 20.46 | 19.85 | 21.02 | 0.35 | 5.6791 |

-

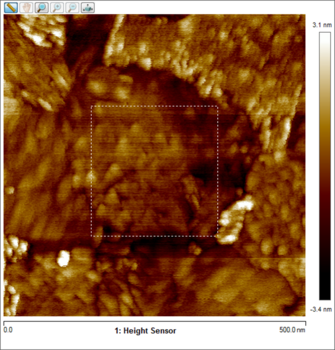

AFM measurement roughness 0.641 nm.

Pernille Voss Larsen, Mikkel Dysseholm Mar and Tanja Amport, DTU Danchip, 2016-2017.

TiO2 on trenches

| TiCl4 | TiCl4 | H2O | H2O | |

|---|---|---|---|---|

| Nitrogen flow | 150 sccm | 150 sccm | 200 sccm | 200 sccm |

| Pulse time | 0.1 s | 0.1 s | 0.1 s | 0.1 s |

Other references

Since the ALD2 is very similar to the ALD1 if the thermal lid is installed you might want to get further information, which can be found here.