Specific Process Knowledge/Lithography/EBeamLithography/FilePreparation

Introduction

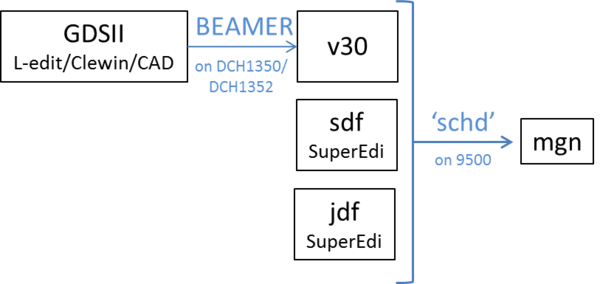

An e-beam exposure requires a v30-file, which contains information on the pattern to write, a jobdeck file (jdf-file), and a schedule file (sdf-file). The sdf- and jdf-file contain information about size and position of substrate, dose, current, and shot step. The sdf-file, jdf-file and v30-file are compiled to a magazine-file (mgn) on the 9500 computer.

When a magazine-file is prepared, the actual shot time can be estimated by the e-beam computer (9500).

Preparing a GDS file

If the layout is asymmetric, the conversion might result in an offset of the final layout onto the wafer. It is therefore recommended to symmetrise the layout, e.g. by inserting small structures in the corners of a rectangle that covers the layout.

How to convert to GDS in L-edit:

1 In L-edit, click File/Export Mask Data/GDSII

2 Choose Default GDSII unit: 1 database unit = 0.001 microns

Even though you do not export hidden layers or un-selected cells, unwanted layers might appear in the final GDSII file. Therefore, after conversion til GDSII, check your layout in a different layout viewer, e.g. CleWin (freeware), or BEAMER.

Converting from GDS to v30 (BEAMER)

The gds-file is converted to a v30-file by using the programme BEAMER. Please read the special BEAMER manual for a more advanced description of the BEAMER program.

- Open BEAMER.

- Drag the ‘Import’-module to the top-right window of Layout Beamer, open the gds-file to convert

- If the pattern has abutting polygons and even overlapping polygons which lead to double exposure, incorrect simulations etc., this can be fixed by running a ‘Heal’ program; drag the ‘HEAL’-module on top of the gds-file

- Drag the ‘Export’-module on top of the gds-file, export to the location ‘C:\1 gds files\name\date’. Export in JEOL52-format and change field-size to 1000µm x 1000 µm (under 'Advanced’). Click RUN on the Export-icon to execute the whole procedure

The gds-file is now converted to v30-format. In order to check the layout pattern double-click on the v30-module and and a VIEW LAYOUT window will open.

Preparing sdf and jdf files

Sdf- and jdf-files should not be created or edited in a regular notepad or wordpad program. Use only SuperEdi, which is freeware and available on the computers in the e-beam room. When you save a sdf- or jdf-file in SuperEdi, make sure to set the line endings to UNIX.

Both the sdf- and jdf-file should carry names using no capital letters.

You can find templates of sdf- and jdf-files in the folder home/eb0/jeoleb/job/templates on the 9500 computer.

Simple sdf and jdf files

sdf-file

The sdf-file contains a series of commands and parameters that specifies jdf filename, type

of cassette, shot pitch and condition file. It also specifies whether the pattern to be exposed requires alignment.

Below, an explanation of the template 'simple.sdf'. Note that semicolon outcomments the text:

___________________________________________________________________________

MAGAZIN 'SIMPLE1' The magazine name is SIMPLE1; max. 20 capital letters

#6 Cassette from slot no. 6 is used

%4A Wafer of 4" in position A is exposed

JDF 'simple',1 Layer block no. 1 of the jdf-file 'simple.jdf' is exposed

ACC 100 Acceleration voltage of 100keV is used

CALPRM '0.2na_ap5' The condition file 0.2na_ap5 is used

DEFMODE 2 Both deflectors are used (default)

RESIST 240 A dose of 240 µC/cm2 is used

SHOT A,8 The shot step between individual beam shots is 4 nm

OFFSET(0,0) An offset of 0 µm is applied in both X and Y

END After exposure, the stage is left empty, i.e. the cassette is unloaded

___________________________________________________________________________

Note that the unit in the SHOT command is in 0.5nm, i.e. 'SHOT A,16' gives a shot pitch of 8nm. If the next user of the machine has loaded a cassette in slot #10 and you wish to load that cassette after exposure, you can finalize the sdf-file with 'END 10'.

jdf-file

The jdf-file contains a series of commands and parameters that specifies what pattern (v30-file) is to be written where on the sample. It also specifies what calibrations are to be performed during writing.

The jdf-file 'simple.jdf' could look like this:

___________________________________________________________________________

JOB/W 'SIMPLE',4 4" wafer, jobname is 'SIMPLE', max. 20 capital letters

PATH DRF5M The DRF5M calibration is used (see section 3.3)

ARRAY (0,3,2000)/(0,3,3000) see note 1

ASSIGN P(1) -> (*,1) Pattern 1 is assigned to row 1-3 coloumn 1

ASSIGN P(2) -> (*,2-3) Pattern 2 is assigned to row 1-3 coloumn 2-3

SKIP (1,1) Nothing is assigned to chip (1,1)

AEND End-command to 'ARRAY'

PEND End-command to 'PATH'

LAYER 1 Start of layer block 1

P(1) 'template1.v30' Pattern 1 defined in 'template1.v30'

P(2) 'template2.v30' Pattern 2 defined in 'template2.v30'

SPPRM 4.0,,,,1.0,1 Beam parameters (default - see section 6.2)

STDCUR 0.22 ;nA Beam current (in nA) used for writing, see note 2

END End of jdf-file

___________________________________________________________________________

Note 1: 9 chips are written, the upper left chip has center in (X,Y) = (0,0). The pitch between the chips is 2 mm in x-direction and 3 mm in y-direction.

Note 2: You should always add 10% to the current defined in 'STDCUR'; this ensures you work well below a scan speed of 100 MHz and thus gives room for a fluctuating current.

___________________________________________________________________________

Examples

| 20 coloums of chips on a wafer; the first 10 coloums of the array is exposed with one shot pitch, the rest of the chips with another. | |

|---|---|

| An array of 20 chips is written on one 4" wafer. The first 10 coloums of the array is defined in layer block no. 1 of the jdf, coloumn 11-20 is defined in layer block no. 2 of the jdf. The two layer blocks uses different beam shot pitch and base dose. The two layer blocks must be called in two different sequences in the sdf-file. | |

|

SDF file MAGAZIN 'LAYERS' #1 %4A JDF 'layers',1 ACC 100 CALPRM '0.2na_ap5' DEFMODE 2 OFFSET(0,0) #1 %4A JDF 'layers',2 ACC 100 CALPRM '0.2na_ap5' DEFMODE 2 OFFSET(0,0) END 1 JDF FILE JOB/W 'TWOLAYERS',4

PATH DRF5M

ARRAY (-10000,20,2000)/( 10000,20,2000)

ASSIGN P(1) -> (1-10,*)

ASSIGN P(2) -> (11-20,*)

AEND

PEND

LAYER 1

P( 1 ) 'test2.v30'

SPPRM 4.0,,,,1.0,1

SHOT A,20

RESIST 220

STDCUR 0.22 ;nA

LAYER 2

P( 2 ) 'test2.v30'

SPPRM 4.0,,,,1.0,1

SHOT A,40

RESIST 250

STDCUR 0.22 ;nA

END

| |

Alignment and global mark detection

Alignment of an e-beamed pattern to an existing pattern on wafer or chip (direct writing mode) requires at least two alignment marks, P and Q, preferably positioned in quadrant II and IV of the wafer or chip (the x-coordinate of the global mark Q must be equal to or larger than the x-coordinate of the global mark P).

Before loading the cassette into the e-beam writer, the wafer or chip should be pre-aligned using the optical pre-aligner setup in the e-beam room. A description of this procedure is included in the main manual of the e-beam writer.

HEIMAP is discarded in direct writing mode, it thus is important to insert height measurements, by the HSWITCH and CHIPAL V1 or CHIPAL V4 command in the sdf-file. The height of the substrate will in either case be measured by a laser beam with a spot size 0.94 mm x 0.08 mm on the substrate.

HSWITCH:

HSWITCH ON,OFF: machine focusses beam to the Height average between P and Q marks

HSWITCH OFF,ON: machine focusses beam to the height average of chip marks

HSWITCH ON,ON: machine focusses beam to the height average of chip marks. The chip mark height will overrule the P and Q mark height during exposure.

If HSWITCH is omitted, HSWITCH ON, ON is default

CHIPAL V1/V4:

The virtual CHIPAL command in the sdf-file, CHIPAL V1 or CHIPAL V4, can be used to measure the height of the substrate at well-defined positions on the substrate, thus correcting for height variations before pattern writing. To use this, HSWITCH should be set to 'HSWITCH OFF,ON' or 'HSWITCH OFF,ON'.

CHIPAL V1: machine measures height at chip mark M1 (machine does not scan the mark) and focusses beam to this height before exposing

CHIPAL V4: machine measures height at chip mark M1, M2, M3 and M4 (machine does not scan the marks) and focusses beam to the average height before exposing

_____________________________________________________________

MAGAZIN 'ALIGN'

#1 Cassette from slot no. 1 is used

%4A Wafer of 4" in position A is exposed

JDF 'align',1 Layer block no. 1 of the jdf-file 'align.jdf' is exposed

ACC 100 Acceleration voltage is 100keV

CALPRM '0.2na_ap5' The condition file 0.2na_ap5 is used

DEFMODE 2 Both deflectors are used (default)

GLMDET S Semi-automatic global mark detection is used

CHIPAL 0 No chip-mark detection is used

HSWITCH OFF,ON Height mesaurements at chip mark positions

RESIST 240 A dose of 240 µC/cm2 is used

SHOT A,8 The shot step between individual beam shots is 4 nm

OFFSET(0,0) An offset of 0 µm is applied in both X and Y

END 1 After exposure, cassette no. 1 is left on stage

______________________________________________________________

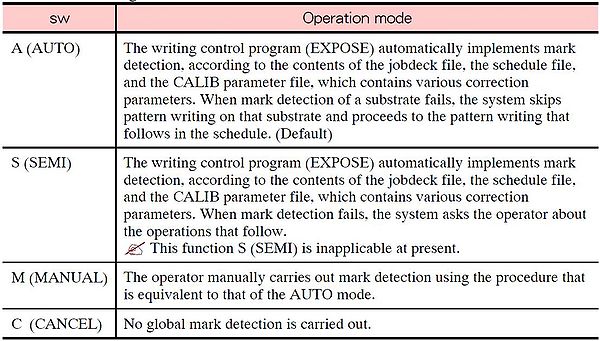

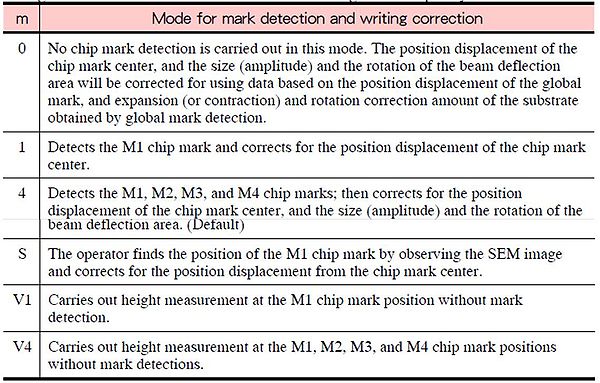

The parameters in the GLMDET-command can be as follows:

And the parameters in the CHIPAL-command can be as follows:

The global- and chip-mark position, size and orientation should be specified in the jdf-file:

______________________________________________________________

JOB/W 'ALIGN',4 4" wafer, jobname is 'SIMPLE'

GLMPOS P=(-7980,180),Q=(7960,-180) Position of P and Q mark

GLMP 4.0,1000.0,t,f see note 1

PATH FT01 use FT01 when aligning, sec. 3.3

ARRAY (0,1,1000)/(0,1,1000) 1 chip starting in (0,0) is written

CHMPOS M1=(-350,350),M2=(350,350), Chipmark pos. in chip coordinate sys.

M3=(350,-350),M4=(-350,-350)

CHMARK 4.0,15.0, t, f see note 1

ASSIGN P(1) -> (*,*) All chips are assigned to pattern 1

AEND End-command to 'ARRAY'

PEND End-command to 'PATH'

LAYER 1 Layer 1 in the v30 file is written

P(1) 'align.v30' Pattern 1 defined in 'align.v30'

SPPRM 4.0,,,,1.0,1 Beam parameters (see section 6.2)

STDCUR 0.22 ;nA Beam current (nA), se note 2.

END End of jdf-file

_______________________________________________________________

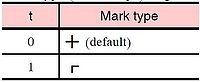

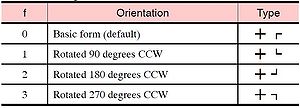

note 1: Width, length, type and orientation of global marks (GLMP) or chipmarks (CHMARK); the settings of the parameters t (type) and f (orientation) are listed in the two tables below:

note 2: Always add 10% to the current in this command to make sure you work well below 100 MHz and thus will not be affected if the current fluctuates above the base current.

Dose variation

The dose modulation is defined in a percentage addition to the base dose, i.e. the final dose, Q, is given by the base dose, RESIST, and modulation, m, by this formula:

Q = (RESIST · (100 + m))/100

In the jdf-file, you assign different layers of the pattern to different dose modulations, m.

If you define the dose variations by different datatype or layertype as described in section 3.2 of the BEAMER manual, you should define the dose for each layer number. You can check the layer numbers in BEAMER when you view the pattern, as seen in section 3.1 and 3.2 in the BEAMER manual.

JOB/W 'TINE1',4 ;4inch wafer PATH DRF5M ARRAY (-500,1,1000)/(500,1,1000) ASSIGN P(1)->((*,*),SHOT1) AEND PEND LAYER 1 P(1) 'tinegjul122013a.v30' SPPRM 4.0,,,,1.0,1 STDCUR 2.2 ;nA SHOT1: MODULAT (( 0, -10) , ( 1, 0) , ( 2, 10)) END

The above example subtracts 10% from the base dose in layer 0 and adds 10% to the base dose in layer 2.

Alternatively, you can make simple dose variations by repeating a simple structure in an array in the jdf-file, and dedicate different part of the array to different doses:

JOB/W 'TINE1',4 ;4inch wafer

PATH DRF5M

ARRAY (-1500,3,1000)/(1500,1,1000)

ASSIGN P(1)->((1,1),SHOT1)

ASSIGN P(1)->((2,1),SHOT2)

ASSIGN P(1)->((3,1),SHOT3)

AEND

PEND

LAYER 1

P(1) 'tinegjul122013b.v30'

SPPRM 4.0,,,,1.0,1

STDCUR 2.2 ;nA

SHOT1: MODULAT (( 0,-10))

SHOT2: MODULAT (( 0,0 ))

SHOT3: MODULAT (( 0,10))

END