Specific Process Knowledge/Lithography/CSAR

| Resist | Polarity | Manufacturer | Comments | Technical reports | Spinner | Developer | Rinse | Remover | Process flows (in docx-format) |

| CSAR | Positive | AllResist | Standard positive resist, approved, very similar to ZEP520. | Allresist_CSAR62_English.pdf,, CSAR_62_Abstract_Allresist.pdf | Manual Spinner 1 (Laurell), Spin Coater Labspin | X AR 600-54/6, MIBK:IPA | IPA | 1165 Remover | Process_Flow_CSAR.docx |

Simple e-beam pattern in this resist has been tested, the results showed on this page. If you have questions to the process or wish to use this e-beam resist, please contact Tine Greibe at tigre@danchip.dtu.dk.

Process Flow

Test of Chemically Semi-Amplified Resist (CSAR); a positive e-beam resist from AllResist (AR-P 6200-2).

| Equipment | Process Parameters | Comments | |

|---|---|---|---|

| Pretreatment | |||

| 4" Si wafers | No Pretreatment | ||

| Spin Coat | |||

| Spin Coater Manual, LabSpin, A-5 | AR-P 6200/2 AllResist E-beam resist

60 sec at various spin speed. Acceleration 4000 s-2, softbake 1 - 5 min at 150 deg Celcius |

Disposal pipette used; clean by N2-gun before use. Use approximately 1.5 ml per 4" wafer, never use a pipette twice. Softbake is not a crucial step, see e-mail correspondence with AllResist here. | |

| Characterization | |||

| Ellipsometer VASE B-1 | 9 points measured on 100 mm wafer | ZEP program used; measured at 70 deg only | |

| E-beam Exposure | |||

| JEOL 9500 E-beam writer, E-1 | Dosepattern 15nm - 100nm,

dose 120-280 muC/cm2 |

Virtual chip mark height detection (CHIPAL V1) used in corner of every dose array | |

| Development | |||

| Fumehood, D-3 | 60 sec in X AR 600-54/6,

60 sec rinse in IPA, N2 Blow dry |

Gentle agitation while developing. After developing, wafer is immersed in beaker with IPA, subsequently blow dried with N2 gun. | |

| Characterization | |||

| Zeiss SEM Supra 60VP, D-3 | 2-3 kV, shortest working distance possible, chip mounted with Al tape | The wafers are diced into smaller pieces and sputter coated with Pt at DTU CEN before SEM inspection; please contact Ramona Valentina Mateiu for further information. | |

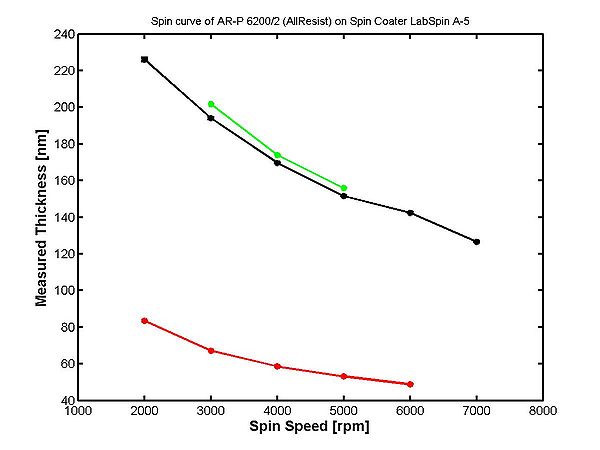

Spin Curves

The thickness is measured on VASE Ellipsometer using a simple Cauchy model for a transparent polymer on Si. The measurements are performed at one incidence angle (70 degrees) only. 9 points on each 4" wafer has been measured; the standard deviation thus representing the homogeinity of the film on the 4" wafers.

Dosepattern has been e-beam exposured and SEM inspected on those wafers marked by silver gray.

| AllResist AR-P 6200/2 spinning on Spin Coater: Manual LabSpin A-5, TIGRE, 09-04-2014. Softbake 5 min @ 150 degC. | ||||||

|---|---|---|---|---|---|---|

| Spin Speed [rpm] | Acceleration [1/s2] | Thickness [nm] | St Dev | |||

| 2000 | 4000 | 225.98 | 0.97 | |||

| 3000 | 4000 | 194.00 | 0.6 | |||

| 4000 | 4000 | 169.57 | 0.32 | |||

| 5000 | 4000 | 151.47 | 0.26 | |||

| 6000 | 4000 | 142.38 | 0.41 | |||

| 7000 | 4000 | 126.59 | 0.36 | |||

| AllResist CSAR on Spin Coater: Manual LabSpin A-5, TIGRE, 16-06-2014. Softbake 2 min @ 150 degC. | ||||||

|---|---|---|---|---|---|---|

| Spin Speed [rpm] | Acceleration [1/s2] | Thickness [nm] | St Dev | |||

| 3000 | 4000 | 201.61 | 1.20 | |||

| 4000 | 4000 | 173.89 | 0.64 | |||

| 5000 | 4000 | 155.91 | 0.65 | |||

| AllResist CSAR 1:1 in anisole, Spin Coater: Manual LabSpin A-5, TIGRE, 16-06-2014. Softbake 2 min @ 150 degC. | ||||||

|---|---|---|---|---|---|---|

| Spin Speed [rpm] | Acceleration [1/s2] | Thickness [nm] | St Dev | |||

| 2000 | 4000 | 83.48 | 0.49 | |||

| 3000 | 4000 | 67.12 | 0.41 | |||

| 4000 | 4000 | 58.64 | 0.44 | |||

| 5000 | 4000 | 53.13 | 0.39 | |||

| 6000 | 4000 | 48.76 | 0.38 | |||

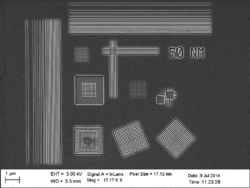

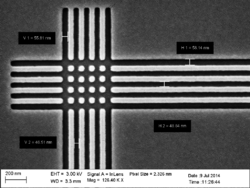

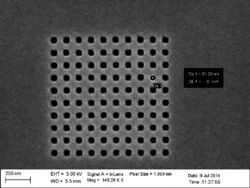

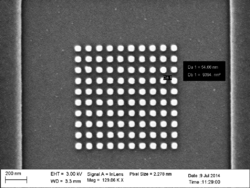

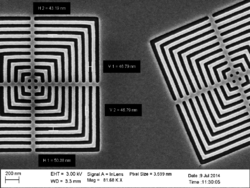

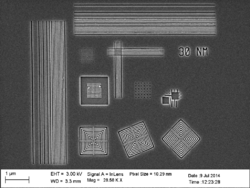

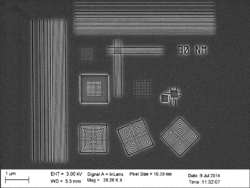

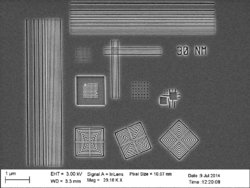

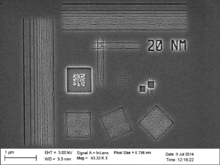

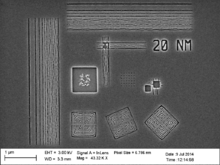

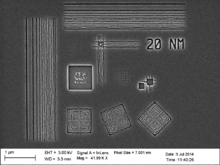

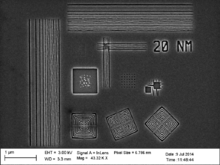

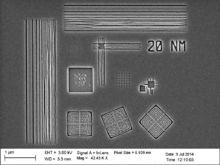

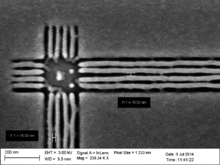

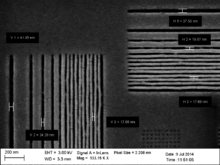

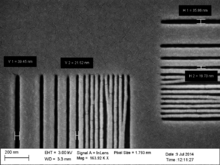

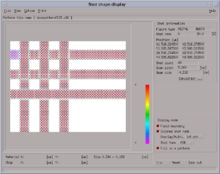

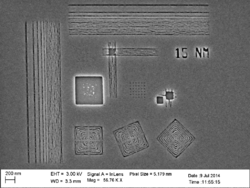

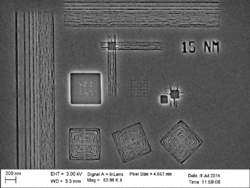

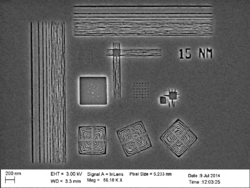

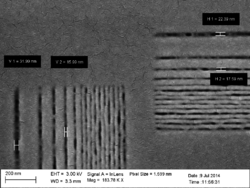

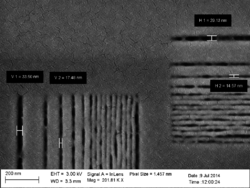

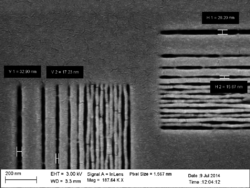

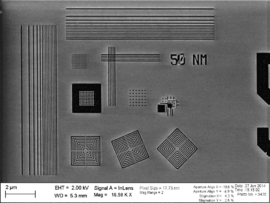

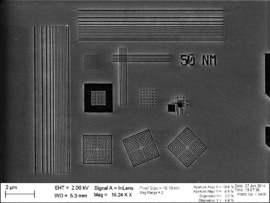

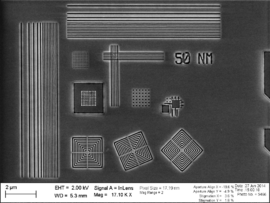

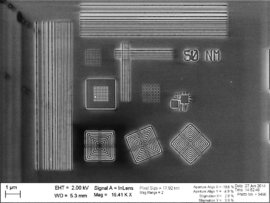

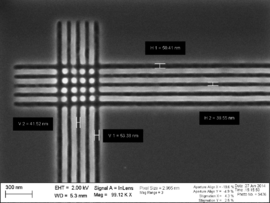

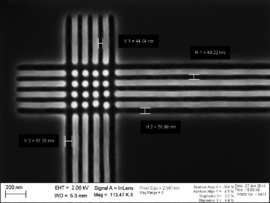

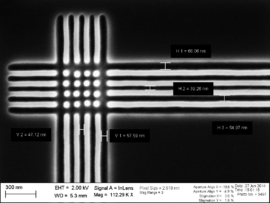

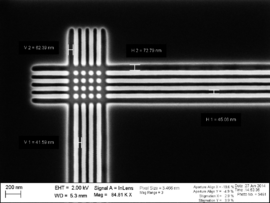

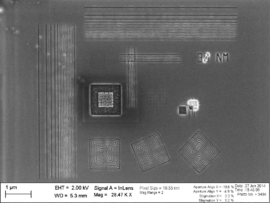

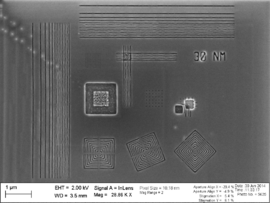

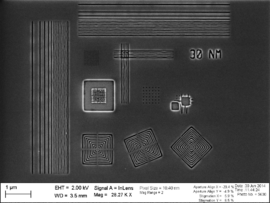

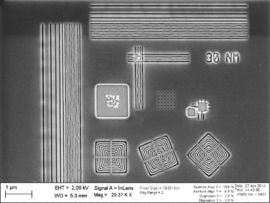

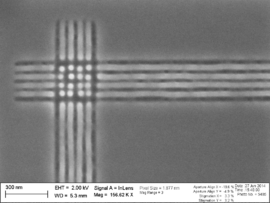

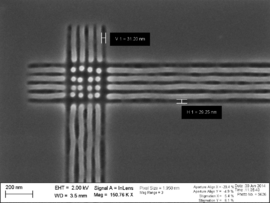

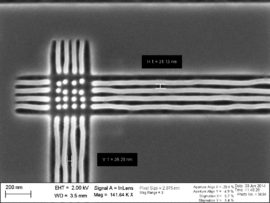

SEM pictures of dosepatterns

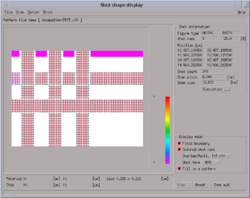

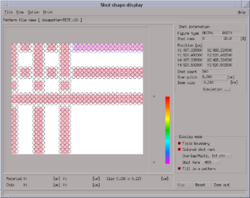

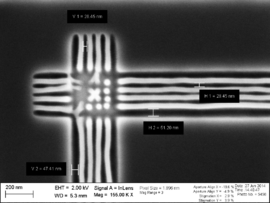

The e-beam exposures presented here are written with 'SHOT A,10', i.e. a shot pitch of 5nm; this pitch works very well for large structures but not so well for 20nm or below. To illustrate this, ACHK screenshot are presented along with SEM inspection picures.

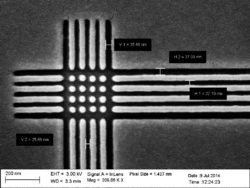

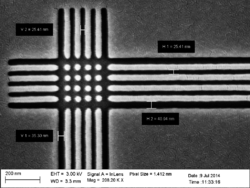

53 nm CSAR

| Process | Equipment | Parameters | Date and initials |

|---|---|---|---|

| Resist | Fumehood D-3 | AR-P 6200/2 AllResist E-beam resist diluted 1:1 in anisole | 16-06-2014 TIGRE |

| Spin Coat | Spin Coater LabSpin A-5 | 1 min @ 5000 rpm, 4000 1/s2, softbake 2 min @ 150 degC, thickness ~53nm | 16-06-2014 TIGRE |

| E-beam exposure | JEOL 9500 E-2 | 0.2 nA, aperture 5, dose 207-242 muC/cm2, SHOT A,10 | 02-07-2014 TIGRE |

| Develop | Fumehood D-3 | SX-AR 600-54/6 60 sec, 60 sec IPA rinse | 08-07-2014 TIGRE |

| Sputter Coat | Cressington 208HR, DTU CEN | 3-5 nm Pt, sputtering | 09-07-2014 TIGRE |

| Characterization | Zeiss SEM Supra 60VP, D-3 | 3 kV, WD below 4mm, conducting tape close to pattern | 09-07-2014, TIGRE |

50nm

| dose [muC/cm2] | 230 | 230 | 230 | 230 | 230 |

|---|---|---|---|---|---|

|

|

|

|

|

30nm

| dose [muC/cm2] | 219 | 230 | 242 | ACHK |

|---|---|---|---|---|

|

|

|

||

|

|

|

|

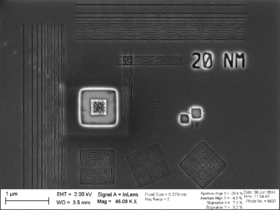

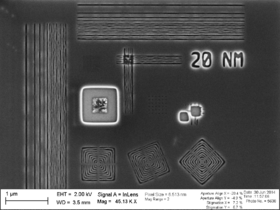

20nm

| dose [muC/cm2] | 207 | 219 | 230 | 242 | 253 | ACHK |

|---|---|---|---|---|---|---|

|

|

|

|

|

||

|

|

|

|

15nm

| dose [muC/cm2] | 242 | 253 | 276 | ACHK |

|---|---|---|---|---|

|

|

|

||

|

|

|

|

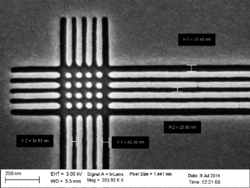

140 nm CSAR

| Process | Equipment | Parameters | Date and initials |

|---|---|---|---|

| Resist | Fumehood D-3 | AR-P 6200/2 AllResist E-beam resist | 2013 (bottle opened) |

| Spin Coat | Spin Coater LabSpin A-5 | 1 min @ 6000 rpm, 4000 1/s2, softbake 5 min @ 150 degC, thickness ~143nm | 09-04-2014 TIGRE |

| E-beam exposure | JEOL 9500 E-2 | 2 nA, aperture 5, dose 207-242 muC/cm2, SHOT A,10 | 10-04-2014 TIGRE |

| Develop | Fumehood D-3 | SX-AR 600-54/6 60 sec, 60 sec IPA rinse | April/May-2014 TIGRE |

| Sputter Coat | Cressington 208HR, DTU CEN | 2-3 nm Pt, sputtering | 22-05-2014 TIGRE |

| Characterization | Zeiss SEM Supra 60VP, D-3 | 2 kV, WD below 4mm, conducting tape close to pattern | 06-06-2014, TIGRE |

50nm

| dose [muC/cm2] | 207 | 219 | 230 | 242 |

|---|---|---|---|---|

|

|

|

| |

|

|

|

|

30nm

| dose [muC/cm2] | 207 | 219 | 230 | 242 |

|---|---|---|---|---|

|

|

|

| |

|

|

|

|

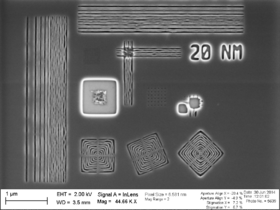

20nm

| dose [muC/cm2] | 230 | 242 | 253 |

|---|---|---|---|

|

|

|