Specific Process Knowledge/Lithography/EBeamLithography/JEOLAlignment

Aligned exposure on JEOL 9500

There is quite a few things to remember in order to align an exposure to an existing pattern. The example below is a step by step guide illustrating global substrate alignment as well as chip alignment. If your job only requires global alignment simply skip the chip alignment part. In the example we assume a layer, L1, is already defined on the substrate and the goal is to align the next layer, L2, to it.

Job preparation

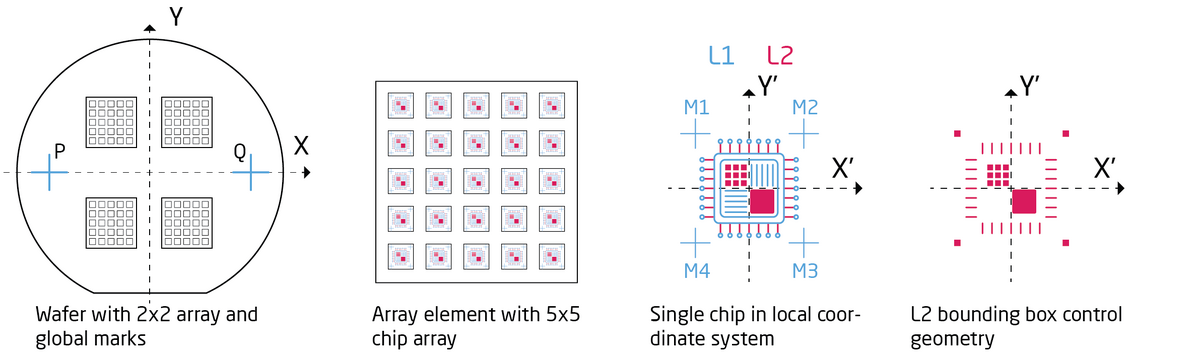

The job illustrated below writes a chip layout in a 5 x 5 matrix into a 2 x 2 matrix as illustrated in the figure. The first layer, L1, has defined global marks at P = (-30000,0) and Q = (30000,0). The local chip marks are placed at M1 = (-450,450), M2 = (450,450), M3 = (450,-450) and M4=(-450,-450). First a global alignment is called via the GLMDET command and subsequently chip alignment is called using the CHIPAL command. The mark positions are stated in the JDF file using the GLMPOS command for PQ marks and the M1 to M4 commands for chip marks. Remember that a V30 file is placed relative to its bounding box center coordinate and hence it might be necessary to control the bounding box extents by adding control geometry (corner marks) if the design is not symmetric around (0,0) in the chip design coordinate system.

The following SDF and JDF files will be used for the example.

;SDF MAGAZIN 'THOPE' #7 %4D JDF 'thope230126',1 ACC 100 CALPRM '6na_ap5' DEFMODE 2 GLMDET A CHIPAL 1 HSWITCH OFF,ON RESIST 250 SHOT A,16 OFFSET(-44,-139) END 7

;JDF

JOB/W 'THOPE',4 ; 4inch wafer

GLMPOS P=(-30000,0),Q=(30000,0)

PATH FT01

ARRAY (-15000,2,30000)/(10000,2,20000)

ASSIGN A(1) -> ((*,*))

1: ARRAY (-4000,5,2000)/(4000,5,2000)

CHMPOS M1=(-450,450),M2=(450,450),M3=(450,-450),M4=(-450,-450)

ASSIGN P(1) -> (*,*)

AEND

PEND

LAYER 1

P(1) 'thope230126.v30'

SPPRM 4.0,,,,1.0,1

STDCUR 6.6

OBJAPT 5

END