Specific Process Knowledge/Lithography/Aligners/Aligner: Maskless 02 processing

Feedback to this page: click here

THIS PAGE IS UNDER CONSTRUCTION

Exposure technology

Aligner: Maskless 02 is not a direct writer. In the maskless aligner, the exposure light is passed through a spatial light modulator, much like in a video projector, and projected onto the substrate, thus exposing an area of the design at a time. The substrate is exposed by scanning the exposure field across the substrate in a succession of stripes.

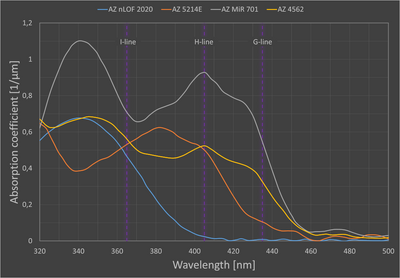

The light source is a laser diode (array) with a wavelength of 375nm (2.8W) or 405nm (8W). The spacial light modulator is a digital micro-mirror device. The individual mirrors of the DMD are switched in order to represent the design, and the laser is flashed in order to yield the desired exposure dose. This image is projected onto the substrate through a lens(system). The projected image yields a pixel size of 160nm X 160nm at wafer scale. The image is scanned across the substrate, in order to expose the entire design, each stripe overlapping (2 or 4 times) in order to minimize uniformity effects and stitching errors.

The writing head of the Aligner: Maskless 02 moves only in the z-direction. Using an optical (or pneumatic) focusing system, the maskless aligner is able to do real-time autofocus. The defocus process parameter is used to compensate offsets in the focusing mechanism, and to optimize printing quality in different resists and varying thicknesses. The stage of the Aligner: Maskless 02 moves only in x and y. It has no theta-axis. All rotation during alignment is thus accomplished by transformation of the input design.

Process Parameters

Exposure dose

Exposure dose relative to exposure at 365nm (Aligner: Maskless 01):

| 375nm | 405nm | |

|---|---|---|

| AZ 5214E | 0.95 | 1.3 |

| AZ 4562 | ? | ? |

| AZ MiR 701 | 1 | 1.2 |

| AZ nLOF 2020 | 3 | NA |

| SU-8 | 10-15 | NA |

Defocus

Exposure mode

(high quality, fast)

Resolution

- 5206E 0.5µm 375nm, dev 2xSP30s

Fast: 60mJ/cm2; defoc -6 (1µm, not optimized)

Quality: 60mJ/cm2; defoc -6 (~750nm, not optimized)

- 5214E 1.5µm 405nm, dev SP60s

Fast: 90mJ/cm2; defoc -2 (1-2µm)

- 5214E 1.5µm 375nm, dev SP60s

Fast: 65mJ/cm2; defoc 2 (~1µm)

Quality: 65mJ/cm2; defoc 2 (~750nm)

- MiR 701 1.5µm 405nm, PEB 60s@110°C dev SP60s

Fast: 200mJ/cm2; defoc -5 (~1µm, not optimized)

- MiR 701 1.5µm 375nm, PEB 60s@110°C dev SP60s

Fast: 170mJ/cm2; defoc -5 (1µm)

Quality: 180mJ/cm2; defoc -6 (750nm)

- nLOF 2020 2µm 375nm, PEB 60s@110°C dev SP60s

Fast: 400mJ/cm2; defoc 5 (~1µm, not optimized)

Quality: 400mJ/cm2; defoc 0 (1µm)

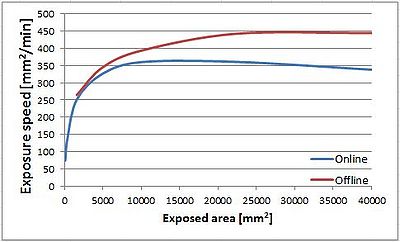

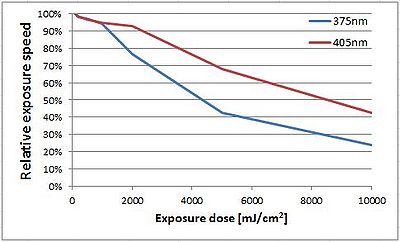

Writing speed

(high quality, fast)

- Speed vs. area (375nm)

- Online

- Offline

- Speed vs. dose (375nm + 405nm)

Features

Substrate centring and flat alignment

During substrate detection, the sample is scanned along the X- and Y-axes, as well as diagonally. From these measurements, the size (diameter) of the substrate is calculated, as well as the stage position matching the center of the substrate. This stage position will be the default origin for the subsequent exposure.

At the end of substrate detection, the sample is scanned twice along the bottom edge (flat), in order to determine the substrate rotation. This angle will be presented in the exposure panel along with the option to expose the design rotated in order to compensate for this angle, i.e. aligned to the flat/edge of the substrate.

- Substrate centering + flat alignment test

Labelling

HIMT\Designs\Labels\labelfile.lbl (tab-delimited ASCII file with special header).

X | Y | UNIT | HEIGHT | UNIT | TITLE

-16000 | -46000 | um | 2000 | um | TARAN DTU Nanolab 20190320

This produces a 2mm high, approximately 32mm long wafer ID at the flat of a 4" wafer.

Some special characters are not allowed (e.g. ';').

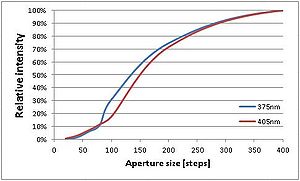

High Aspect Ratio (DOF) mode

Aligner: Maskless 02 is configured with the so-called "Write Mode I", which uses a higher demagnification, higher NA lens system to achieve higher resolution. This reduces the depth of focus (technically depth of field), making it more difficult to achieve good lithographic results in thicker resist coatings. The theoretical DOF of Aligner: Maskless 02 is 0.3µm, compared to 1µm for Aligner: Maskless 01. In order to enable processing of thick resists, the Aligner: Maskless 02 has been configured with the High Aspect Ratio Mode, which uses a variable aperture in the optical path to decrease the (illumination) NA of the system, thus increasing the DOF at the expense of intensity and resolution limit.

Dose factor for different wavelength and aperture settings:

| Wavelength | 375nm | 405nm | ||

|---|---|---|---|---|

| Aperture setting | Large (100) | X-Large (60) | Large (100) | X-Large (60) |

| Intensity measurements | 3.3 | 17.4 | 5.7 | 14.6 |

| 150µm SU-8 dose tests | ~3 | ~10 | NA | NA |

| 1.5µm AZ MiR 701 dose tests | 7.5 | 20.8 | 6.7 | 18.0 |

| 10µm AZ 4562 dose tests | ? | ? | ? | ? |

Results from acceptance test:

| 150µm SU-8 | |

|---|---|

| Standard (800)

6000 mJ/cm2 |

|

| Large (100)

16500 |

|

| X-Large (60)

55000 |

|

Alignment

Top Side Alignment

- 4 marks (before final installation)

- Scaling (375nm, high res camera)

Back Side Alignment

- Tested, 2-3µm error in X observed

- Corrected

Advanced Field alignment (TSA)

- 4 marks, 25 fields (375nm, high res camera)

- Scaled first print, 10 fields (375nm, high res camera)

- 4 marks, 25 fields (405nm, high res camera)