Specific Process Knowledge/Etch/Wet Titanium Etch: Difference between revisions

Created page with "Ething of Titanium can be done either wet or dry. For wet etching please see below on this page. Dry etching can be done either with [[Specific Process Knowledge/Etch/ICP Meta..." |

No edit summary |

||

| Line 1: | Line 1: | ||

'''Feedback to this page''': '''[mailto:wetchemistry@danchip.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.danchip.dtu.dk/index.php/Specific_Process_Knowledge/Etch/Wet_Titanium_Etch click here]''' | |||

Ething of Titanium can be done either wet or dry. For wet etching please see below on this page. Dry etching can be done either with [[Specific Process Knowledge/Etch/ICP Metal Etcher|ICP]] using Chlorine chemistry or with [[Specific Process Knowledge/Etch/IBE/IBSD Ionfab 300|IBE]] by sputtering with Ar ions. | Ething of Titanium can be done either wet or dry. For wet etching please see below on this page. Dry etching can be done either with [[Specific Process Knowledge/Etch/ICP Metal Etcher|ICP]] using Chlorine chemistry or with [[Specific Process Knowledge/Etch/IBE/IBSD Ionfab 300|IBE]] by sputtering with Ar ions. | ||

Revision as of 10:16, 21 March 2013

Feedback to this page: click here

Ething of Titanium can be done either wet or dry. For wet etching please see below on this page. Dry etching can be done either with ICP using Chlorine chemistry or with IBE by sputtering with Ar ions.

Wet etching of Titanium

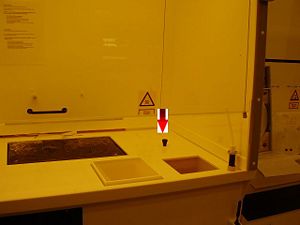

Wet Etch of Titanium can take place in this pp tank or in a beaker in this fume hood

We have two solutions for wet titanium etching:

- BHF

- Cold RCA1

Do it by making your own set up in a beaker in a fume hood - preferably in cleanroom 2 or 4. BHF etching can also take place in the PP-etch bath in the fume hood in cleanroom 2.

Comparing the two solutions

| BHF | Cold RCA1 | |

|---|---|---|

| General description | Etch of titanium with or without photoresist mask. | Etch of titanium (as stripper or with eagle resist). |

| Chemical solution | HF:NH4F | NH3OH:H2O2:H2O - 1:1:5 |

| Process temperature | Room temperature | Room temperature |

| Possible masking materials |

Photoresist (1.5 µm AZ5214E) |

Eagle resist |

| Etch rate |

Not known (it bubbles while etching) |

Not known |

| Batch size |

1-5 4" in beaker 1-25 wafers at a time in PP-etch bath |

1-5 4" wafer at a time |

| Etch bath | Beaker or PP-etch bath in the fume hood in cleanroom 2. | Beaker |

| Allowed materials |

No restrictions when used in beaker or PP-etch bath in the fume hood in cleanroom 2. Make a note on the beaker of which materials have been processed. |

No restrictions when used in beaker. Make a note on the beaker of which materials have been processed. |