Specific Process Knowledge/Etch/IBE⁄IBSD Ionfab 300/IBE magnetic stack etch: Difference between revisions

Appearance

No edit summary |

|||

| Line 51: | Line 51: | ||

{| border="1" cellspacing="1" cellpadding="2" | {| border="1" cellspacing="1" cellpadding="2" | ||

![[image:SIMS_end_point_detection.png|300x300px|thumb| | ![[image:SIMS_end_point_detection.png|300x300px|thumb|center|The endpoint for etching is determined by the integrated SIMS]] | ||

|} | |} | ||

End point detection is achieved by SIMS, and the etch rate is approximately 25 Nm/min. | End point detection is achieved by SIMS, and the etch rate is approximately 25 Nm/min. | ||

Resist stripping can be hard due to burned resist, to remedy this try to lover the current. Changing the currect will chance the sidewall angle and new studies of etch profiles will be necessary. For help, discussion and further info please contact Kristian Hagsted Rasmussen. | Resist stripping can be hard due to burned resist, to remedy this try to lover the current. Changing the currect will chance the sidewall angle and new studies of etch profiles will be necessary. For help, discussion and further info please contact Kristian Hagsted Rasmussen. | ||

Revision as of 14:21, 27 September 2012

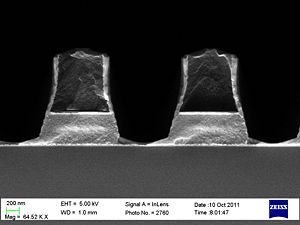

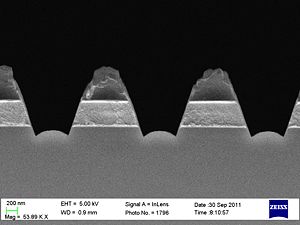

Results of Design of Experiments optimization of magnetic stack etching

Process parameters for the acceptance test

| Parameter | Ti etch acceptance |

|---|---|

| Neutalizer current [mA] | 450 |

| RF Power [W] | 800 |

| Beam current [mA] | 400 |

| Beam voltage [V] | 500 |

| Beam accelerator voltage | 500 |

| Ar flow to neutralizer [sccm] | 5.0 |

| Ar flow to beam [sccm] | 10.0 |

| Rotation speed [rpm] | 20 |

| Stage angle [degrees] | 5 |

| Helium backside cooling [Torr] | 37.5 |

Some SEM profile images of the etched stacks

Endpoint detection with SIMS

|

|---|

End point detection is achieved by SIMS, and the etch rate is approximately 25 Nm/min. Resist stripping can be hard due to burned resist, to remedy this try to lover the current. Changing the currect will chance the sidewall angle and new studies of etch profiles will be necessary. For help, discussion and further info please contact Kristian Hagsted Rasmussen.