| Recipe settings

|

Comments

|

SEM gallery

|

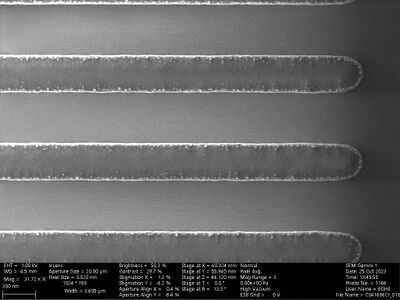

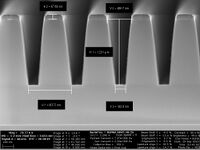

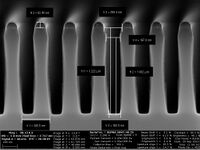

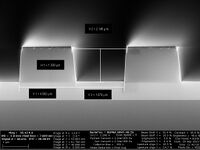

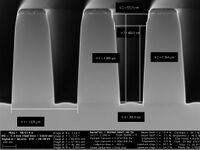

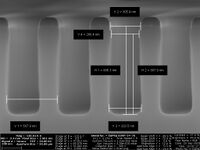

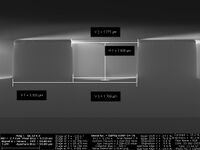

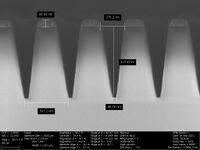

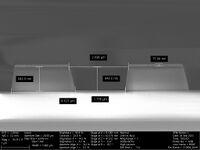

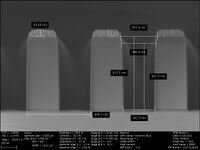

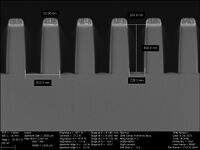

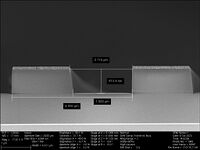

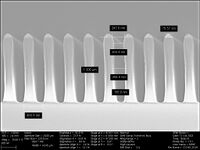

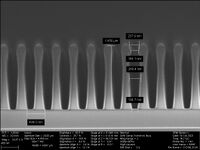

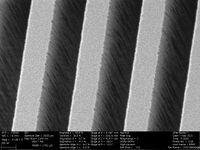

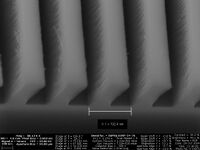

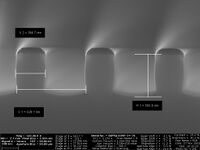

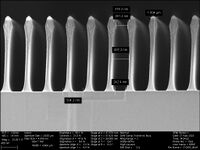

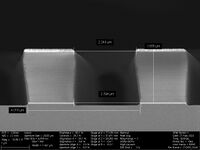

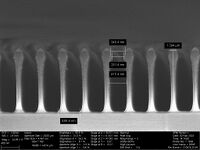

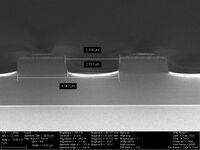

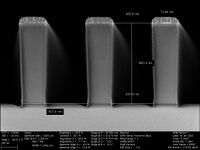

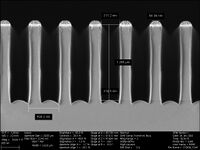

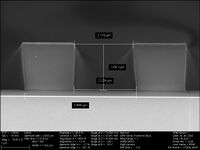

- On 6" wafer

- Coil Power [W]:2500

- Platen Power [W]: 200

- Platen temperature [oC]: 20

- H2 flow [sccm]:25.6

- C4F8 flow [sccm]: 25.6

- He flow [sccm]:448.7

- Pressure:Fully open APC valve (8-9 mTorr)

- Electromagnetic coils (EM) 'outer coil' / 'inner coil':'2 A' / '30 A'

- PLEASE DO NOT RUN WITH THESE SETTINGS FOR MORE THAN 6 MIN

|

text

|

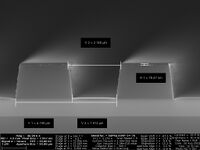

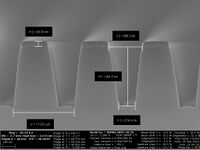

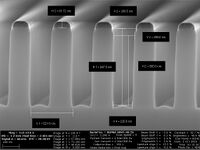

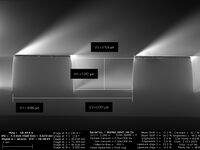

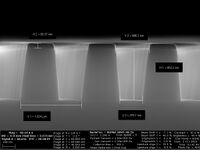

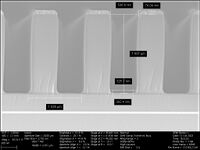

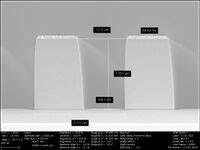

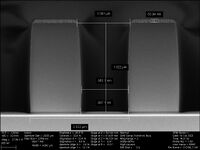

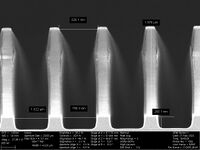

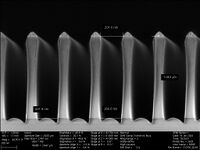

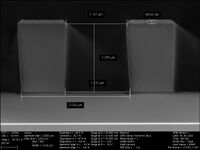

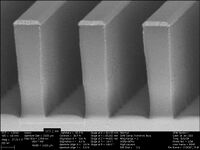

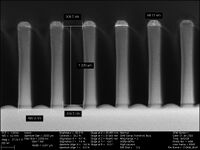

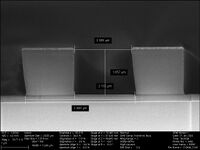

- SiO2 etch with Cr mask on full wafer 6 min etch

-

-

-

-

-

-

|

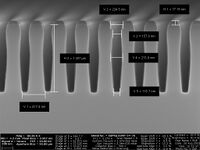

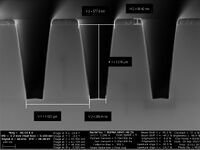

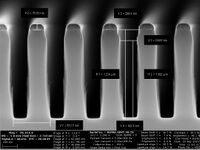

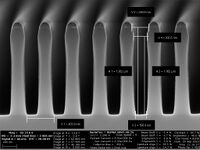

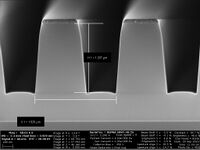

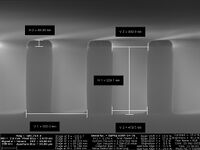

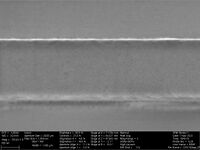

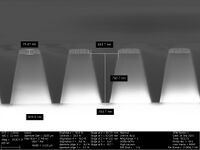

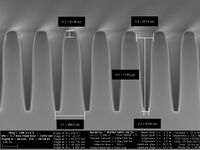

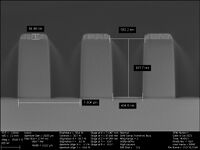

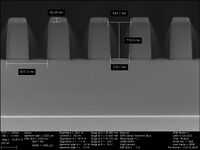

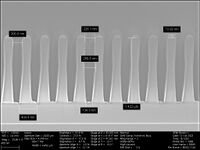

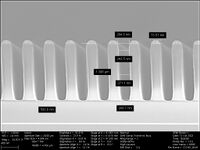

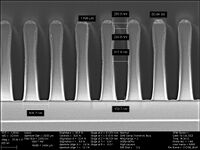

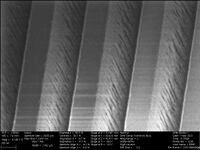

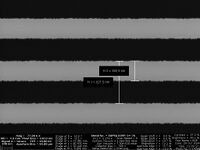

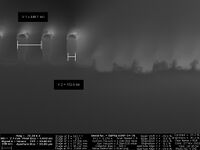

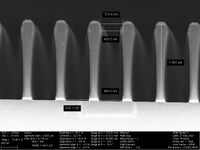

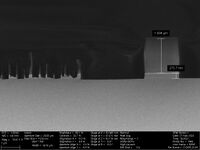

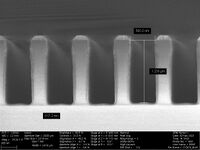

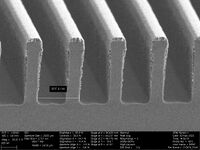

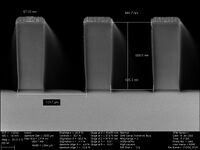

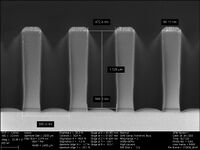

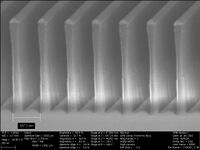

- Piece on Si carrier

- Coil Power [W]:2500

- Platen Power [W]: 200

- Platen temperature [oC]: 20

- H2 flow [sccm]:25.6

- C4F8 flow [sccm]: 25.6

- He flow [sccm]:448.7

- Pressure:Fully open APC valve (8-9 mTorr)

- Electromagnetic coils (EM) 'outer coil' / 'inner coil':'2 A' / '30 A'

- PLEASE DO NOT RUN WITH THESE SETTINGS FOR MORE THAN 6 MIN

|

More sidewall passivation on chip than on full wafer

|

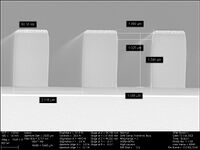

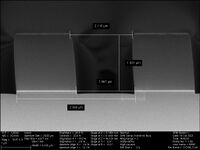

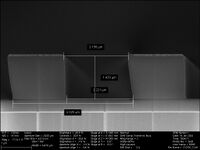

- SiO2 etch with Cr mask on wafer piece on Si carrier 6 min etch

-

-

-

-

-

-

|

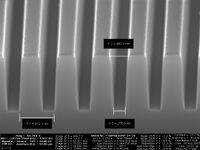

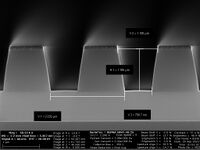

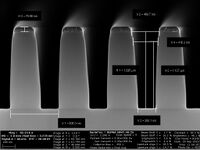

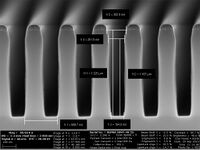

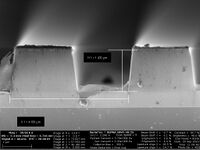

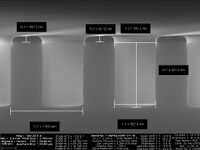

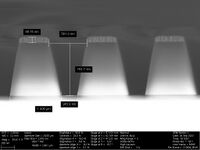

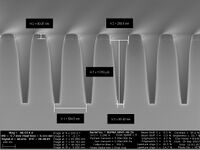

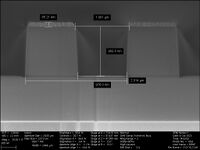

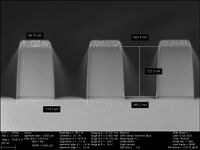

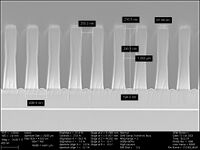

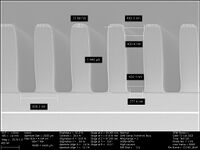

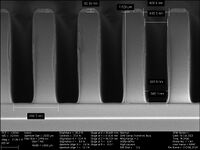

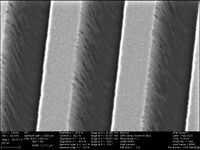

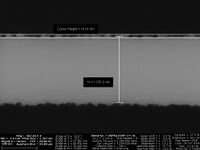

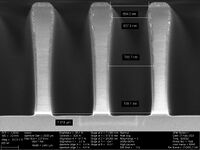

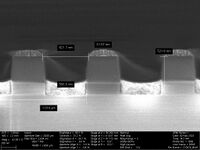

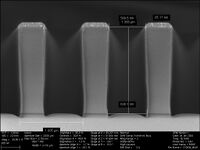

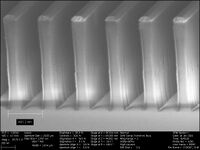

- Coil Power [W]:2500

- Platen Power [W]: 200

- Platen temperature [oC]: 20

- H2 flow [sccm]:0

- C4F8 flow [sccm]: 25.6

- He flow [sccm]:448.7

- Pressure:Fully open APC valve (8-9 mTorr)

- Electromagnetic coils (EM) 'outer coil' / 'inner coil':'2 A' / '30 A'

- PLEASE DO NOT RUN WITH THESE SETTINGS FOR MORE THAN 6 MIN

|

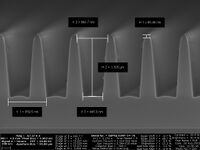

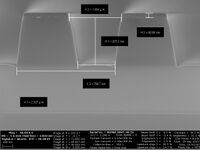

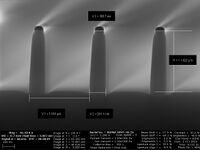

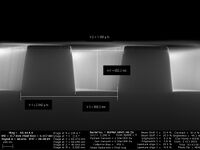

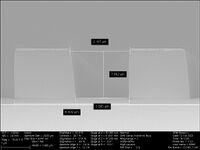

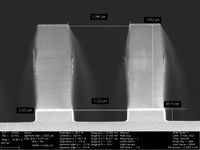

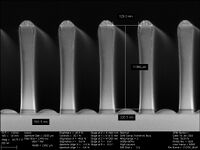

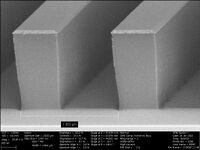

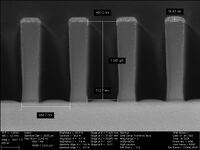

Less sidewall passivation from removing the H2

|

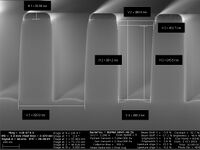

- SiO2 etch with Cr mask on wafer piece on Si carrier 6 min etch, H2:0sccm

-

-

-

-

-

-

|

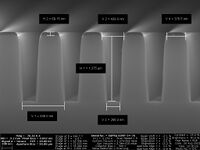

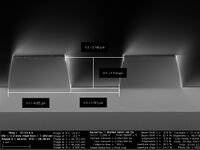

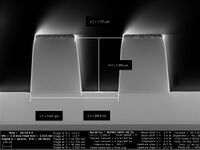

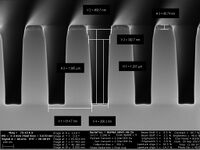

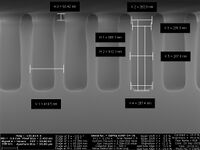

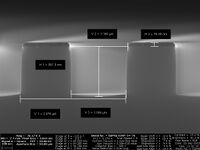

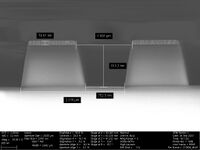

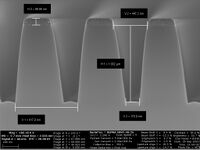

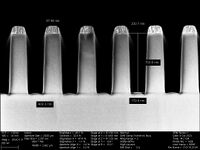

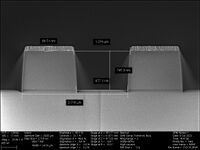

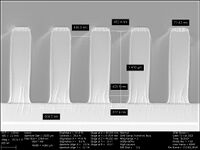

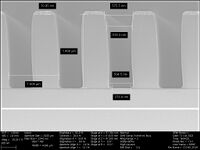

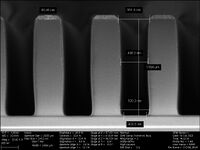

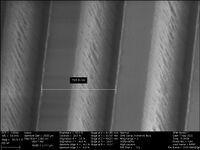

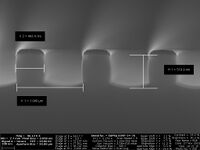

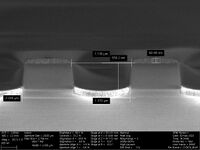

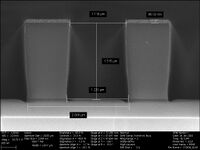

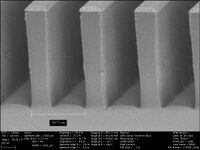

- Coil Power [W]:2500

- Platen Power [W]: 200

- Platen temperature [oC]: 20

- H2 flow [sccm]:0

- O2 flow [sccm]: 5

- C4F8 flow [sccm]: 25.6

- He flow [sccm]:448.7

- Pressure:Fully open APC valve (8-9 mTorr)

- Electromagnetic coils (EM) 'outer coil' / 'inner coil':'2 A' / '30 A'

- PLEASE DO NOT RUN WITH THESE SETTINGS FOR MORE THAN 6 MIN

|

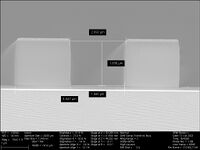

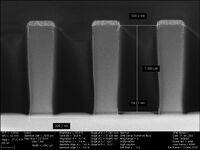

Not a large effect from adding a little O2

|

- SiO2 etch with Cr mask on wafer piece on Si carrier 6 min etch, H2:0sccm, O2:5sccm

-

-

-

-

-

-

|

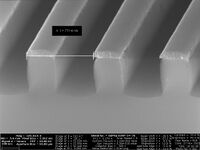

- Coil Power [W]:2500

- Platen Power [W]: 200

- Platen temperature [oC]: 20

- H2 flow [sccm]:0

- O2 flow [sccm]: 0

- C4F8 flow [sccm]: 13.0

- He flow [sccm]:225

- Pressure:Fully open APC valve (3.35 mTorr)

- Electromagnetic coils (EM) 'outer coil' / 'inner coil':'2 A' / '30 A'

- PLEASE DO NOT RUN WITH THESE SETTINGS FOR MORE THAN 6 MIN

|

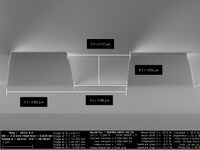

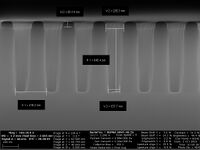

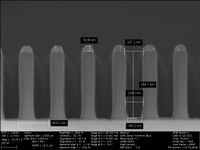

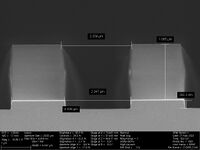

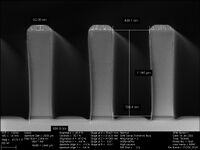

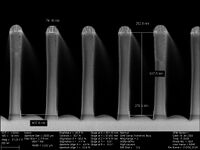

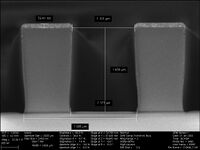

Reducing total flow rate and thereby the pressure gives less passivation/redeposition. Sidewall roughness not so bad.

|

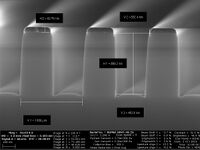

- SiO2 etch with Cr mask on wafer piece on Si carrier 6 min etch, H2:0sccm, C4F8:13sccm He:225sccm, Pressure:3.35mTorr

-

-

-

-

-

-

-

-

-

|

- Coil Power [W]:1200

- Platen Power [W]: 150

- Platen temperature [oC]: 20

- H2 flow [sccm]:0

- O2 flow [sccm]: 0

- C4F8 flow [sccm]: 13.0

- He flow [sccm]:225

- Pressure:Fully open APC valve (3.35 mTorr)

- Electromagnetic coils (EM) 'outer coil' / 'inner coil':'2 A' / '30 A'

- PLEASE DO NOT RUN WITH THESE SETTINGS FOR MORE THAN 6 MIN

|

Reducing the coil power a lot and platen power a little gives more sidewall passivation/redeposition

|

- SiO2 etch with Cr mask on wafer piece on Si carrier 6 min etch, H2:0sccm, C4F8:13sccm He:225sccm, Pressure:3.35mTorr; platen power 150W, coil power:1200W

-

-

-

-

-

-

|

- Coil Power [W]:1200

- Platen Power [W]: 150

- Platen temperature [oC]: 20

- H2 flow [sccm]:0

- O2 flow [sccm]: 10

- C4F8 flow [sccm]: 13.0

- He flow [sccm]:215

- Pressure:Fully open APC valve (3.35 mTorr)

- Electromagnetic coils (EM) 'outer coil' / 'inner coil':'2 A' / '30 A'

- PLEASE DO NOT RUN WITH THESE SETTINGS FOR MORE THAN 6 MIN

|

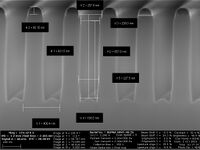

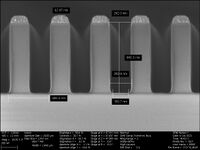

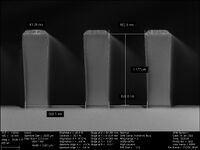

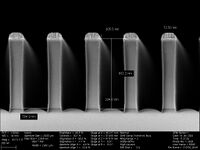

Adding oxygen reduces the passivation/redeposition

|

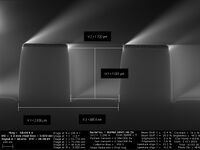

- SiO2 etch with Cr mask on wafer piece on Si carrier 6 min etch, H2:0sccm, C4F8:13sccm He:215sccm O2:10sccm, Pressure:3.6mTorr; platen power 150W, coil power:1200W

-

-

-

-

-

-

|

- Coil Power [W]:1200

- Platen Power [W]: 150

- Platen temperature [oC]: 20

- H2 flow [sccm]:0

- O2 flow [sccm]: 20

- C4F8 flow [sccm]: 13.0

- He flow [sccm]:205

- Pressure:Fully open APC valve (3.35 mTorr)

- Electromagnetic coils (EM) 'outer coil' / 'inner coil':'2 A' / '30 A'

- PLEASE DO NOT RUN WITH THESE SETTINGS FOR MORE THAN 6 MIN

|

Adding more oxygen reduces further the passivation/redeposition but some trenching appears.

|

- SiO2 etch with Cr mask on wafer piece on Si carrier 6 min etch, H2:0sccm, C4F8:13sccm He:205sccm O2:20sccm, Pressure:3.6mTorr; platen power 150W, coil power:1200W

-

-

-

-

-

-

-

|

- Coil Power [W]:1800

- Platen Power [W]: 150

- Platen temperature [oC]: 20

- H2 flow [sccm]:0

- O2 flow [sccm]: 10

- C4F8 flow [sccm]: 13.0

- He flow [sccm]:215

- Pressure:Fully open APC valve (3.35 mTorr)

- Electromagnetic coils (EM) 'outer coil' / 'inner coil':'2 A' / '30 A'

- PLEASE DO NOT RUN WITH THESE SETTINGS FOR MORE THAN 6 MIN

|

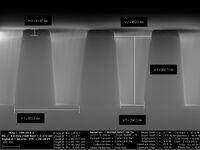

Increasing coil power reduces trenching but increases passivation/redeposition

|

- SiO2 etch with Cr mask on wafer piece on Si carrier 6 min etch, H2:0sccm, C4F8:13sccm He:215sccm O2:10sccm, Pressure:3.6mTorr; platen power 150W, coil power:1800W

-

-

-

-

-

-

|

- Coil Power [W]:1800

- Platen Power [W]: 150

- Platen temperature [oC]: 20

- H2 flow [sccm]:0

- O2 flow [sccm]: 20

- C4F8 flow [sccm]: 13.0

- He flow [sccm]:205

- Pressure:Fully open APC valve (3.6 mTorr)

- Electromagnetic coils (EM) 'outer coil' / 'inner coil':'2 A' / '30 A'

- PLEASE DO NOT RUN WITH THESE SETTINGS FOR MORE THAN 6 MIN

|

Adding more O2 reduces the sidewall passivation/redeposition

|

|

- Coil Power [W]:1200

- Platen Power [W]: 100

- Platen temperature [oC]: 20

- H2 flow [sccm]:0

- O2 flow [sccm]: 20

- C4F8 flow [sccm]: 13.0

- He flow [sccm]:205

- Pressure:Fully open APC valve (3.6 mTorr)

- Electromagnetic coils (EM) 'outer coil' / 'inner coil':'2 A' / '30 A'

- PLEASE DO NOT RUN WITH THESE SETTINGS FOR MORE THAN 6 MIN

|

Running with the lower coil power and reducing the platen power also seems to reduced the sidewall passivatin/redeposition, but etch rate goes down

|

|

- Coil Power [W]:1200

- Platen Power [W]: 100

- Platen temperature [oC]: 20

- H2 flow [sccm]:0

- O2 flow [sccm]: 20

- C4F8 flow [sccm]: 13.0

- He flow [sccm]:205

- Pressure:Fully open APC valve (3.6 mTorr)

- Electromagnetic coils (EM) 'outer coil' / 'inner coil':'2 A' / '30 A'

- PLEASE DO NOT RUN WITH THESE SETTINGS FOR MORE THAN 6 MIN

|

Repeating with longer etch time to etch 1500 nm down. Unfortunately this damaged the hardware due to the EM coils getting too hot.

|

|

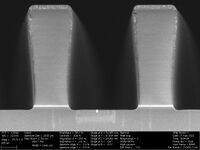

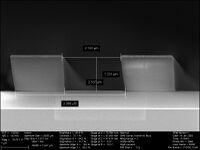

- Coil Power [W]:1800

- Platen Power [W]: 150

- Platen temperature [oC]: 20

- H2 flow [sccm]:0

- O2 flow [sccm]: 20

- C4F8 flow [sccm]: 13.0

- He flow [sccm]:205

- Pressure:Fully open APC valve (3.6 mTorr)

- Electromagnetic coils (EM) 'outer coil' / 'inner coil':'2 A' / '30 A'

- PLEASE DO NOT RUN WITH THESE SETTINGS FOR MORE THAN 6 MIN

|

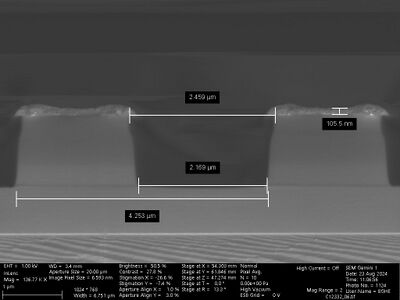

Running 1800W/150W at increased time to etch down to 1500 nm.

|

- C10161 SiO2 etch with Cr mask on wafer piece on Si carrier 10 min etch, H2:0sccm, C4F8:13sccm He:205sccm O2:20sccm, Pressure:3.6mTorr; platen power 150W, coil power:1800W

-

-

-

-

-

-

-

-

|

- Coil Power [W]:1200

- Platen Power [W]: 100

- Platen temperature [oC]: 20

- H2 flow [sccm]:0

- O2 flow [sccm]: 20

- C4F8 flow [sccm]: 13.0

- He flow [sccm]:205

- Pressure:Fully open APC valve (3.9 mTorr)

- Electromagnetic coils (EM) 'outer coil' / 'inner coil':'0 A' / '0 A'

|

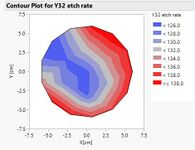

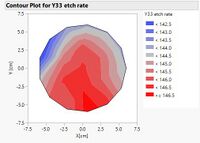

Repeating the 1200W/100W recipes at 14 min but without the EM coils. For this recipe the uniformity over the wafer improved from removing the EM coils, so no need for those and now the recipe could run 14 min without damaging the hardware. The profile looked as before. After removing the Cr I looked from the top and with a tilted view and saw the the sidewall roughness was very bad.

|

|

- Coil Power [W]:2500

- Platen Power [W]: 100

- Platen temperature [oC]: 20

- H2 flow [sccm]:0

- O2 flow [sccm]: 20

- C4F8 flow [sccm]: 13.0

- He flow [sccm]:205

- Pressure:Fully open APC valve (3.9 mTorr)

- Electromagnetic coils (EM) 'outer coil' / 'inner coil':'0 A' / '0 A'

|

Tried high coil power and low platen power. This seemed to give som undercutting,especially on the narrow lines. The smallest has been etched away. The etch rate was very low

|

- SiO2 etch with Cr mask on wafer piece on Si carrier 14 min etch, EM:0/0 H2:0sccm, C4F8:13sccm He:205sccm O2:20sccm, Pressure:3.9mTorr; platen power 100W, coil power:2500W

-

-

-

-

-

|

- Coil Power [W]:2500

- Platen Power [W]: 200

- Platen temperature [oC]: 20

- H2 flow [sccm]:0

- O2 flow [sccm]: 0

- C4F8 flow [sccm]: 13.0

- He flow [sccm]:225

- Pressure:Fully open APC valve (3.9 mTorr)

- Electromagnetic coils (EM) 'outer coil' / 'inner coil':'0 A' / '0 A'

|

Increasing the platen power and and removing the oxygen helped on the under cutting but the lines are still very narrow at the bottom. It also increased the etch rate

|

- SiO2 etch with Cr mask on wafer piece on Si carrier 14 min etch, EM:0/0 H2:0sccm, C4F8:13sccm He:225sccm O2:0sccm, Pressure:3.9mTorr; platen power 200W, coil power:2500W

-

-

-

-

-

-

-

|

- 14 min

- Coil Power [W]:2500

- Platen Power [W]: 200

- Platen temperature [oC]: 20

- H2 flow [sccm]:0

- O2 flow [sccm]: 20

- C4F8 flow [sccm]: 13.0

- He flow [sccm]:205

- Pressure:Fully open APC valve (3.9 mTorr)

- Electromagnetic coils (EM) 'outer coil' / 'inner coil':'0 A' / '0 A'

|

Adding the oxygen again further increased the etch rate and reduced the CD (Critical Dimension) of the Cr mask.

|

- SiO2 etch with Cr mask on wafer piece on Si carrier 14 min etch, EM:0/0 H2:0sccm, C4F8:13sccm He:205sccm O2:20sccm, Pressure:3.9mTorr; platen power 200W, coil power:2500W

-

-

-

-

-

-

|

- Back to start setting without EM coils - 14 min

- Coil Power [W]:2500

- Platen Power [W]: 200

- Platen temperature [oC]: 20

- H2 flow [sccm]:25.6

- O2 flow [sccm]: 0

- C4F8 flow [sccm]: 25.6

- He flow [sccm]:448.7

- Pressure:Fully open APC valve (8-9 mTorr)

- Electromagnetic coils (EM) 'outer coil' / 'inner coil':'0 A' / '0 A'

|

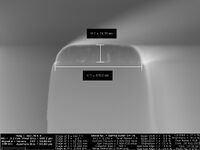

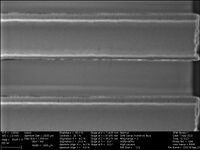

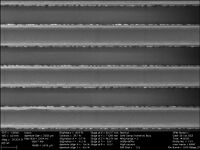

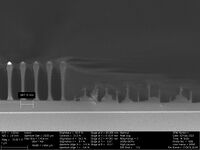

I repeated the start setting but without the EM coils. This gives a very none uniform etch over the wafer where in some parts it deposites instead of etching. The profile of 800 nm oitch look fairly good but a closer look reveals the the sidewall is very rough from either redeposition or polymerization. this cannot be removed with a O2 plasma.

|

- SiO2 etch with Cr mask on wafer piece on Si carrier 14 min etch, EM:0/0

-

-

-

-

-

-

-

-

-

|

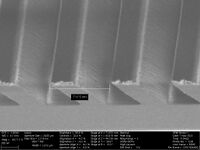

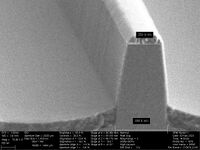

- Coil Power [W]:600

- Platen Power [W]: 50

- Platen temperature [oC]: 20

- H2 flow [sccm]:0

- O2 flow [sccm]: 10

- C4F8 flow [sccm]: 6.5

- He flow [sccm]:100

- Pressure:Fully open APC valve (<2 mTorr)

- Electromagnetic coils (EM) 'outer coil' / 'inner coil':'0 A' / '0 A'

|

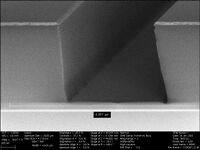

Due to the large sidewall roughness I decided to try and run at lower powers because it looked at some images like an ionbonbardment effect. First try with 600W/50W. The profile looks fairly good but still with some sidewall roughness. there is also some trenching and the Cr mask looks has a facet all the way down to the SiO2. The is also some bowing.

|

- C10751: SiO2 etch with Cr mask on wafer piece on Si carrier 20 min etch, EM:0/0 H2:0sccm, C4F8:6.5sccm He:100sccm O2:10sccm, Pressure:?mTorr; platen power 50W, coil power:600W

-

-

-

-

-

-

|

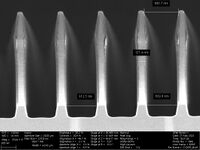

- Coil Power [W]:300

- Platen Power [W]: 25

- Platen temperature [oC]: 20

- H2 flow [sccm]:0

- O2 flow [sccm]: 10

- C4F8 flow [sccm]: 6.5

- He flow [sccm]:100

- Pressure:Fully open APC valve (<2 mTorr)

- Electromagnetic coils (EM) 'outer coil' / 'inner coil':'0 A' / '0 A'

|

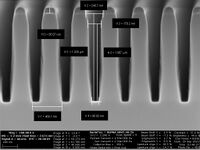

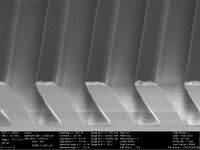

Even lower powers: 300W/25W. The profiles looks better with less roughness but also mush slower etch rate, so not as deep as the previous.

|

- C10752: SiO2 etch with Cr mask on wafer piece on Si carrier 30 min etch, EM:0/0 H2:0sccm, C4F8:6.5sccm He:100sccm O2:10sccm, Pressure:?mTorr; platen power 25W, coil power:300W

-

-

-

-

-

-

|

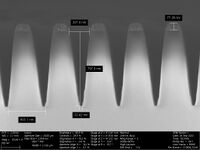

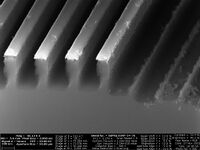

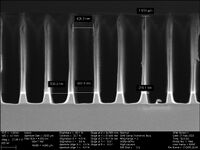

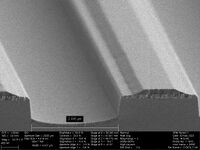

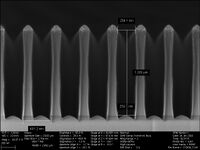

- 45 min

- Coil Power [W]:300

- Platen Power [W]: 25

- Platen temperature [oC]: 20

- H2 flow [sccm]:0

- O2 flow [sccm]: 10

- C4F8 flow [sccm]: 6.5

- He flow [sccm]:100

- Pressure:Fully open APC valve (<2 mTorr)

- Electromagnetic coils (EM) 'outer coil' / 'inner coil':'0 A' / '0 A'

|

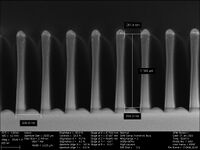

Repeating with longer etch time. Low sidewall roughness, less faceting of the Cr mask. Still some trenching and bowing or negative tapering of the profile.

|

- C10834: SiO2 etch with Cr mask on wafer piece on Si carrier 45 min etch, EM:0/0 H2:0sccm, C4F8:6.5sccm He:100sccm O2:10sccm, Pressure:?mTorr; platen power 25W, coil power:300W

-

-

-

-

-

-

-

-

-

-

-

-

|

- Coil Power [W]:300

- Platen Power [W]: 20

- Platen temperature [oC]: 20

- H2 flow [sccm]:0

- O2 flow [sccm]: 10

- C4F8 flow [sccm]: 6.5

- He flow [sccm]:100

- Pressure:Fully open APC valve (<2 mTorr)

- Electromagnetic coils (EM) 'outer coil' / 'inner coil':'0 A' / '0 A'

|

Decreased the platen power a little to see if this could remove the trenching. Not much different from the last.

|

- C10844: SiO2 etch with Cr mask on wafer piece on Si carrier 50 min etch, EM:0/0 H2:0sccm, C4F8:6.5sccm He:100sccm O2:10sccm, Pressure:?mTorr; platen power 20W, coil power:300W

-

-

-

-

-

-

|