Specific Process Knowledge/Lithography/EBeamLithography/AR-P 617: Difference between revisions

Appearance

| Line 37: | Line 37: | ||

{| style="border: none; border-spacing: 0; margin: 1em auto; text-align: center;" | {| style="border: none; border-spacing: 0; margin: 1em auto; text-align: center;" | ||

|- | |- | ||

| [[image: | | [[image:Arp617contrastcurve.png|800px]] | ||

|- | |- | ||

| colspan="1" style="text-align: center;| | | colspan="1" style="text-align: center;| | ||

Revision as of 12:51, 7 February 2024

AR-P 617 is a positive PMMA based E-beam resist from Allresist. Process information provided by Allresist can be found here.

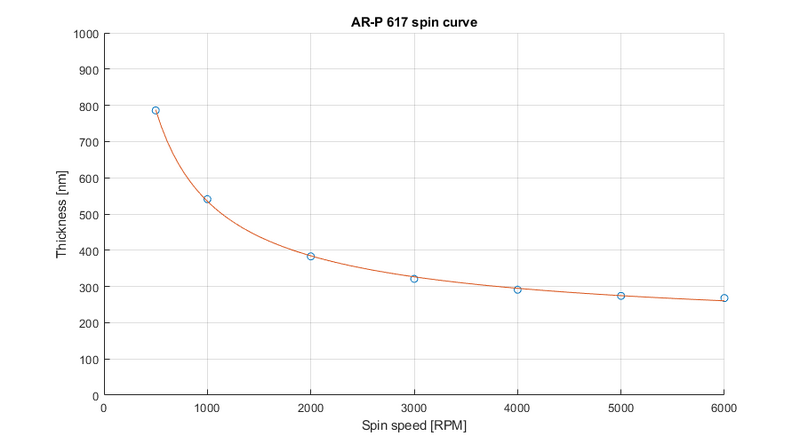

Spin coating

AR-P 617 can be spin coated on LabSpin 2 and 3 using the CSAR/PMMA bowlset. A spin curve for AR-P 617.06 is provided below. Process parameters are:

- Date: January 22nd 2024

- Coater: LabSpin 3

- Substrate: 2" Si

- Acceleration: 1000 RPM/s

- Time: 60 s

- Baking temperature: 200C (setpoint at 222C)

- Baking time: 120 s

|

|

AR-P 617.06 spin curve. |

Resulting resist thickness can be determined as y = axb+c, where y is thickness [nm], x is spin speed [RPM], a = 65274, b = -0.748 and c = 163.1.

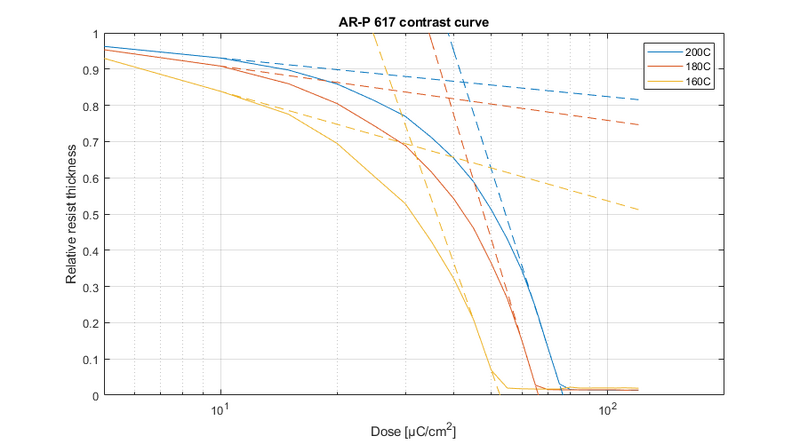

Contrast curve

A contrast curve for AR-P 617.06 is provided below based on exposure at 100 kV for doses from 2.5 to 200 µC/cm2. The dose clear is dependent on softbake temperature, in this case 200C and 180C is used. Process parameters are:

- Date: February 5th 2024

- Coater: LabSpin 2

- Substrate: 2" Si

- Acceleration: 1000 RPM/s

- Time: 60 s

- Baking temperature: 200C, 180C and 160C

- Baking time: 120 s

- Exposure: 100 kV (JEOL 9500)

- Development: AR 600-50 for 90 seconds

- Stopper: IPA for 30 seconds + blow dry with nitrogen

|

|

AR-P 617.06 contrast curve. |