Specific Process Knowledge/Etch/DRIE-Pegasus/Pegasus-4/SiO2 Etch/Cr mask: Difference between revisions

Appearance

| Line 364: | Line 364: | ||

|- | |- | ||

| | | | ||

*Coil Power [W]:1200 | *'''Coil Power [W]:1200''' | ||

*Platen Power [W]: 100 | *'''Platen Power [W]: 100''' | ||

*Platen temperature [<sup>o</sup>C]: 20 | *Platen temperature [<sup>o</sup>C]: 20 | ||

*H2 flow [sccm]:0 | *H2 flow [sccm]:0 | ||

| Line 372: | Line 372: | ||

*He flow [sccm]:205 | *He flow [sccm]:205 | ||

*Pressure:Fully open APC valve (3.9 mTorr) | *Pressure:Fully open APC valve (3.9 mTorr) | ||

*Electromagnetic coils (EM) 'outer coil' / 'inner coil':'0 A' / '0 A' | *'''Electromagnetic coils (EM) 'outer coil' / 'inner coil':'0 A' / '0 A'''' | ||

| | | | ||

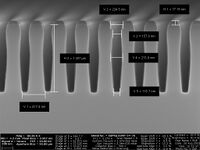

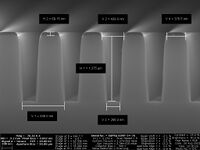

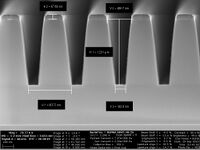

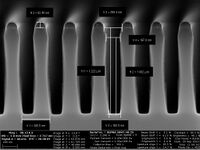

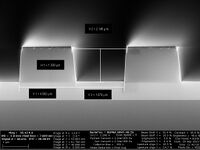

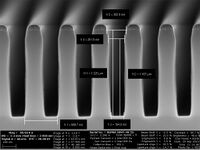

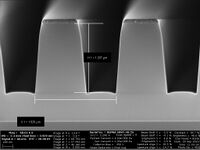

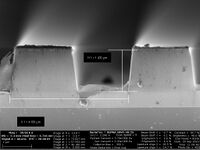

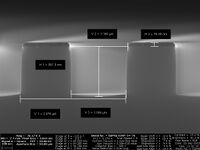

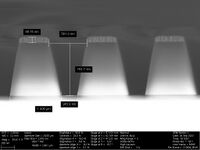

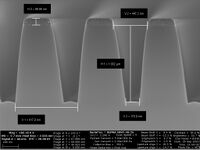

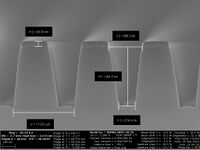

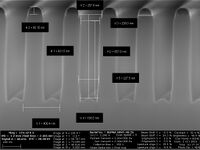

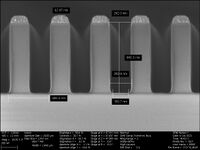

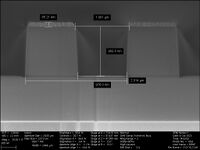

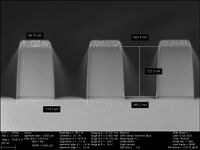

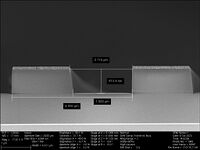

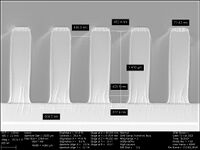

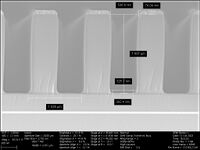

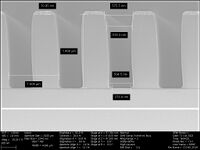

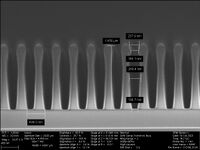

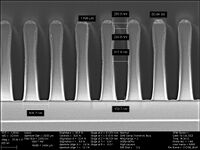

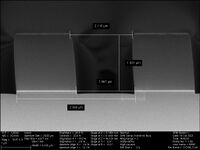

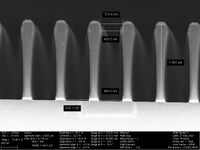

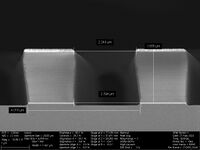

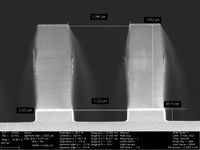

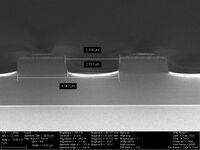

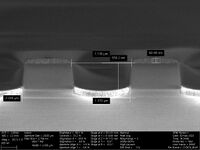

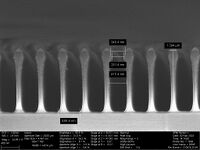

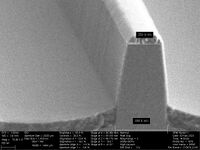

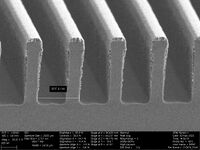

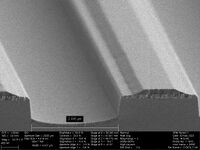

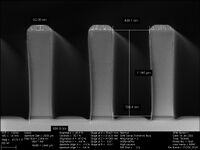

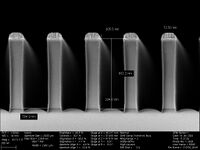

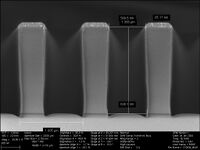

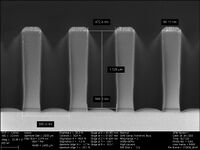

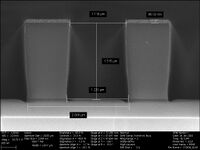

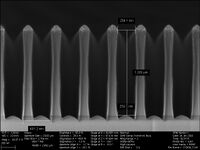

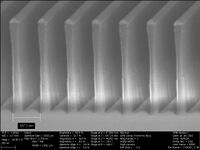

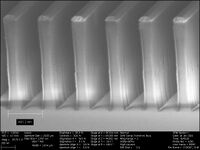

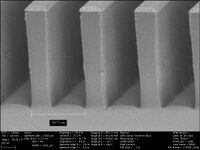

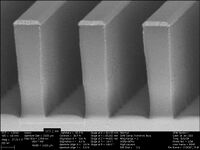

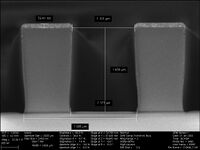

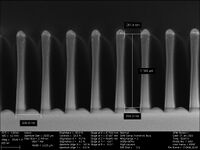

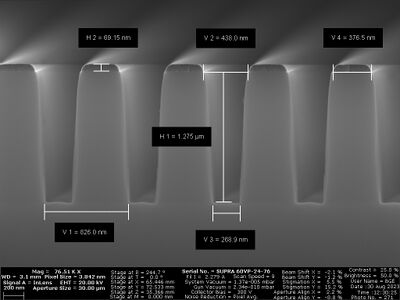

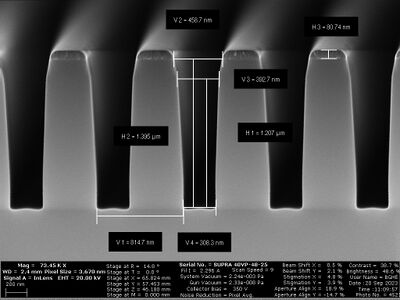

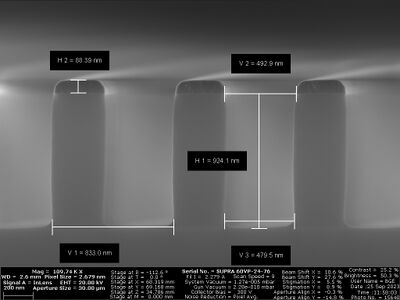

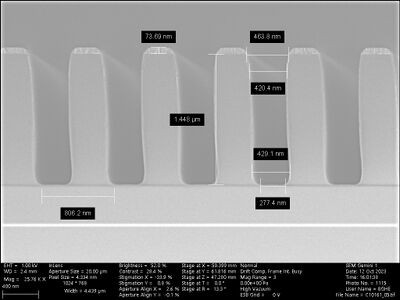

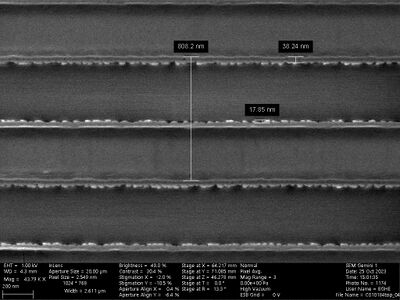

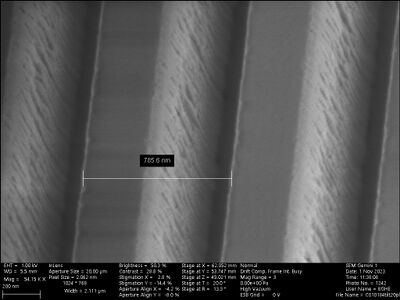

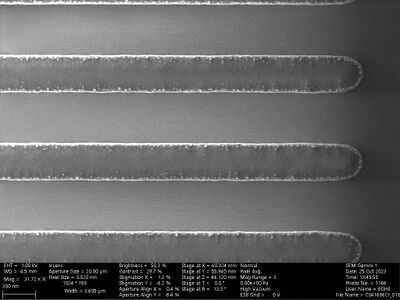

<gallery caption="SiO2 etch with Cr mask on wafer piece on Si carrier 14 min etch, EM:0/0 H2:0sccm, C4F8:13sccm He:205sccm O2:20sccm, Pressure:3.9mTorr; platen power 100W, coil power:1200W" perrow="7" widths="200px" heights="150px"> | <gallery caption="SiO2 etch with Cr mask on wafer piece on Si carrier 14 min etch, EM:0/0 H2:0sccm, C4F8:13sccm He:205sccm O2:20sccm, Pressure:3.9mTorr; platen power 100W, coil power:1200W" perrow="7" widths="200px" heights="150px"> | ||

| Line 385: | Line 385: | ||

|- | |- | ||

| | | | ||

*Coil Power [W]:2500 | *'''Coil Power [W]:2500''' | ||

*Platen Power [W]: 100 | *Platen Power [W]: 100 | ||

*Platen temperature [<sup>o</sup>C]: 20 | *Platen temperature [<sup>o</sup>C]: 20 | ||

| Line 405: | Line 405: | ||

| | | | ||

*Coil Power [W]:2500 | *Coil Power [W]:2500 | ||

*Platen Power [W]: 200 | *'''Platen Power [W]: 200''' | ||

*Platen temperature [<sup>o</sup>C]: 20 | *Platen temperature [<sup>o</sup>C]: 20 | ||

*H2 flow [sccm]:0 | *H2 flow [sccm]:0 | ||

| Line 425: | Line 425: | ||

|- | |- | ||

| | | | ||

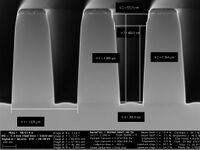

*'''14 min''' | |||

*Coil Power [W]:2500 | *Coil Power [W]:2500 | ||

*Platen Power [W]: 200 | *Platen Power [W]: 200 | ||

| Line 445: | Line 446: | ||

|- | |- | ||

| | | | ||

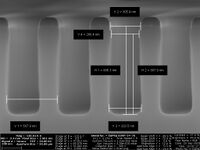

*'''Back to start setting without EM coils - 14 min''' | |||

*Coil Power [W]:2500 | *Coil Power [W]:2500 | ||

*Platen Power [W]: 200 | *Platen Power [W]: 200 | ||

| Line 468: | Line 470: | ||

|- | |- | ||

| | | | ||

*Coil Power [W]:600 | *'''Coil Power [W]:600''' | ||

*Platen Power [W]: 50 | *'''Platen Power [W]: 50''' | ||

*Platen temperature [<sup>o</sup>C]: 20 | *Platen temperature [<sup>o</sup>C]: 20 | ||

*H2 flow [sccm]:0 | *H2 flow [sccm]:0 | ||

*O2 flow [sccm]: 10 | *'''O2 flow [sccm]: 10''' | ||

*C<sub>4</sub>F<sub>8</sub> flow [sccm]: 6.5 | *'''C<sub>4</sub>F<sub>8</sub> flow [sccm]: 6.5''' | ||

*He flow [sccm]:100 | *'''He flow [sccm]:100''' | ||

*Pressure:Fully open APC valve (<2 mTorr) | *Pressure:Fully open APC valve ('''<2 mTorr''') | ||

*Electromagnetic coils (EM) 'outer coil' / 'inner coil':'0 A' / '0 A' | *Electromagnetic coils (EM) 'outer coil' / 'inner coil':'0 A' / '0 A' | ||

| | | | ||

| Line 488: | Line 490: | ||

|- | |- | ||

| | | | ||

*Coil Power [W]:300 | *'''Coil Power [W]:300''' | ||

*Platen Power [W]: 25 | *'''Platen Power [W]: 25''' | ||

*Platen temperature [<sup>o</sup>C]: 20 | *Platen temperature [<sup>o</sup>C]: 20 | ||

*H2 flow [sccm]:0 | *H2 flow [sccm]:0 | ||

| Line 508: | Line 510: | ||

|- | |- | ||

| | | | ||

*'''45 min''' | |||

*Coil Power [W]:300 | *Coil Power [W]:300 | ||

*Platen Power [W]: 25 | *Platen Power [W]: 25 | ||

| Line 535: | Line 538: | ||

| | | | ||

*Coil Power [W]:300 | *Coil Power [W]:300 | ||

*Platen Power [W]: 20 | *'''Platen Power [W]: 20''' | ||

*Platen temperature [<sup>o</sup>C]: 20 | *Platen temperature [<sup>o</sup>C]: 20 | ||

*H2 flow [sccm]:0 | *H2 flow [sccm]:0 | ||

Revision as of 13:57, 6 February 2024

Feedback to this page: click here

Unless otherwise stated, all content in this section was done by Berit Herstrøm, DTU Nanolab

SiO2 trench etching with Cr mask

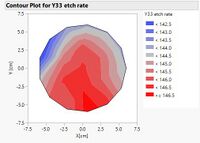

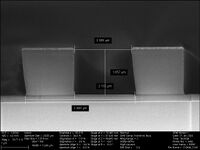

| Start parameters, variations noted in the gallery headline | Recipe name: no 10 with lower platen power |

|---|---|

| Coil Power [W] | 2500 |

| Platen Power [W] | 200 |

| Platen temperature [oC] | 20 |

| H2 flow [sccm] | 25.6 |

| C4F8 flow [sccm] | 25.6 |

| He flow [sccm] | 448.7 |

| Pressure | Fully open APC valve (8-9 mTorr) |

| Electromagnetic coils (EM) 'outer coil' / 'inner coil' | '2 A' / '30 A' (PLEASE DO NOT RUN WITH THESE SETTINGS FOR MORE THAN 6 MIN) |

- 100 nm Cr mask etched in ICP metal with 500nm DUV neg resist (NUV 2300-0.5) and 65 nm barc.

Results

| Temporary conclusions on how the process parameters affect the results in this study: | What process parameters affect the results? |

|

|

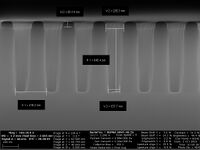

Profile SEM images

| Recipe settings | SEM gallery |

|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

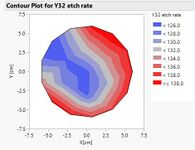

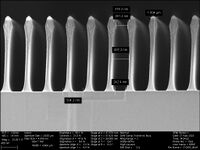

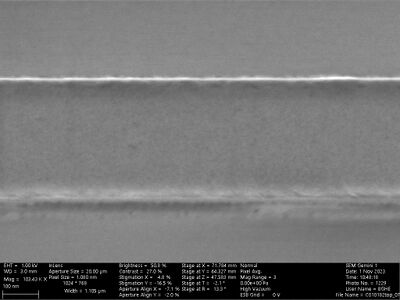

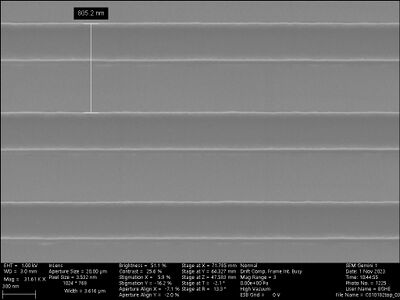

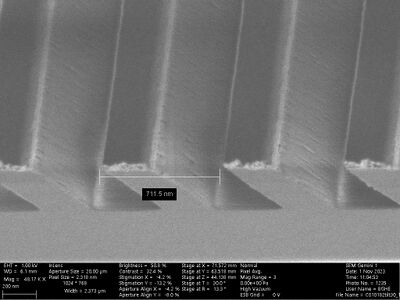

Profile, top view at tilted SEM images on 800 nm pitch and 50% duty cycle ( look at the Cr mask in top of the page

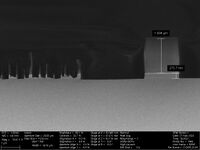

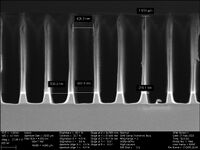

- SiO2 etch with Cr mask on full wafer 6 min etch

- SiO2 etch with Cr mask on wafer piece on Si carrier 6 min etch

- SiO2 etch with Cr mask on wafer piece on Si carrier 6 min etch, H2:0sccm

- SiO2 etch with Cr mask on wafer piece on Si carrier 6 min etch, H2:0sccm, O2:5sccm

- SiO2 etch with Cr mask on wafer piece on Si carrier 6 min etch, H2:0sccm, C4F8:13sccm He:225sccm, Pressure:3.35mTorr

- SiO2 etch with Cr mask on wafer piece on Si carrier 6 min etch, H2:0sccm, C4F8:13sccm He:225sccm, Pressure:3.35mTorr; platen power 150W, coil power:1200W

- SiO2 etch with Cr mask on wafer piece on Si carrier 6 min etch, H2:0sccm, C4F8:13sccm He:215sccm O2:10sccm, Pressure:3.6mTorr; platen power 150W, coil power:1200W

- SiO2 etch with Cr mask on wafer piece on Si carrier 6 min etch, H2:0sccm, C4F8:13sccm He:205sccm O2:20sccm, Pressure:3.6mTorr; platen power 150W, coil power:1200W

- SiO2 etch with Cr mask on wafer piece on Si carrier 6 min etch, H2:0sccm, C4F8:13sccm He:215sccm O2:10sccm, Pressure:3.6mTorr; platen power 150W, coil power:1800W

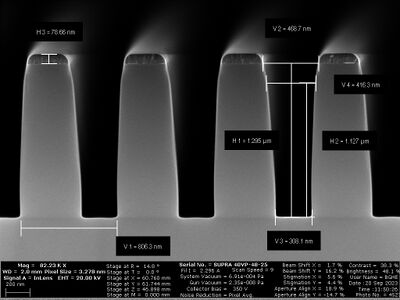

- SiO2 etch with Cr mask on wafer piece on Si carrier 6 min etch, H2:0sccm, C4F8:13sccm He:205sccm O2:20sccm, Pressure:3.6mTorr; platen power 150W, coil power:1800W

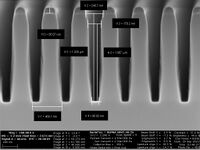

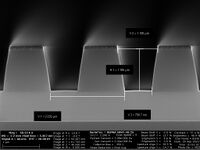

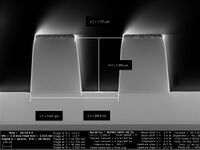

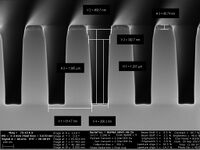

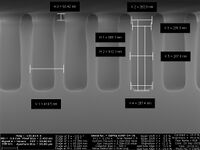

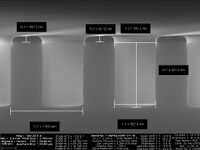

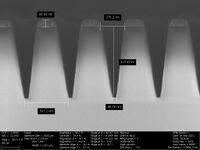

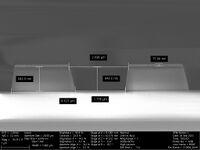

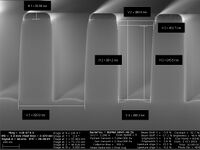

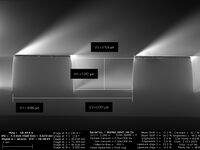

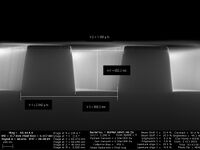

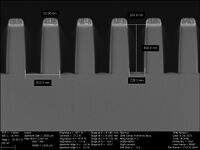

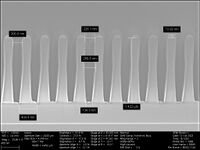

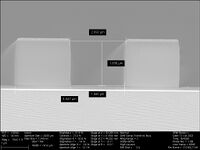

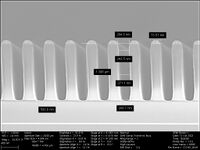

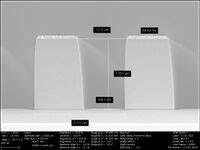

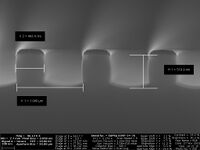

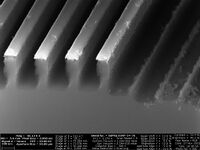

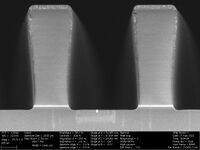

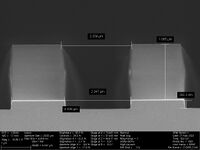

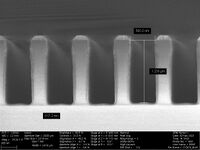

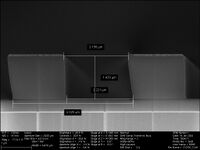

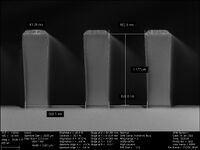

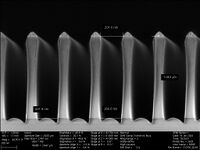

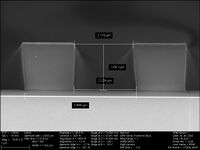

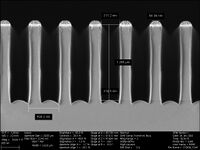

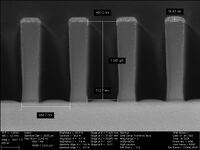

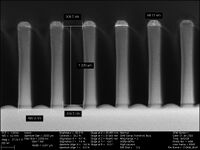

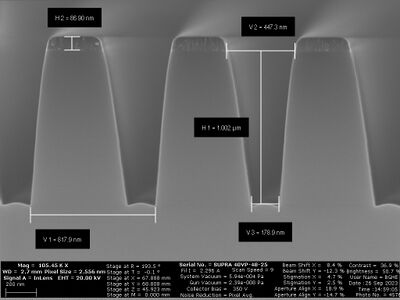

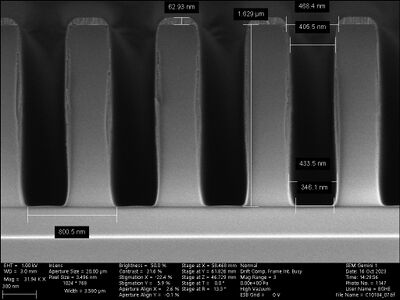

-

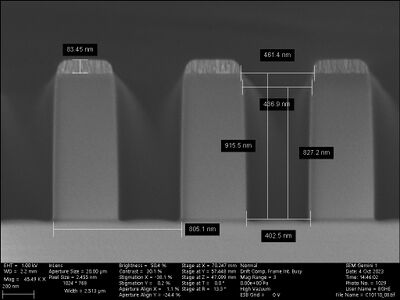

pitch 800 nm

Top 461 nm

@edge 437 nm

bottom 402 nm

height 916 nm

height from edge 827 nm

Cr left 83.5 nm

selectivity 55.5

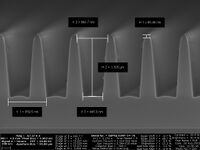

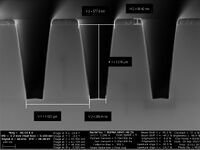

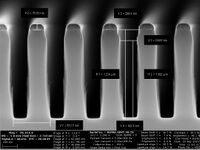

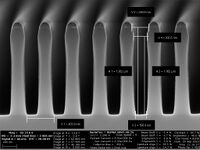

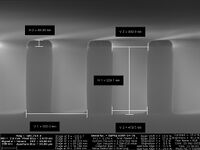

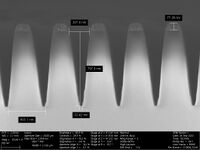

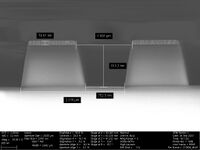

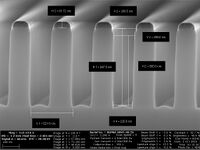

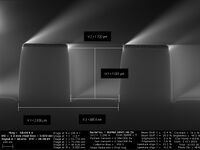

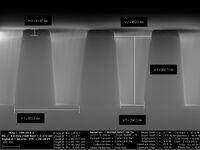

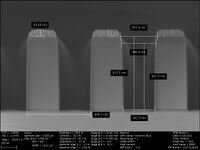

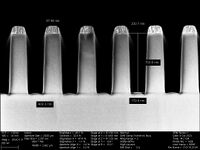

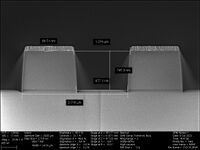

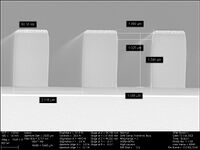

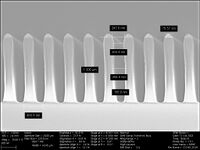

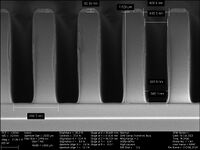

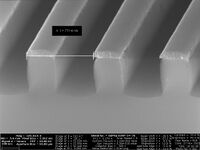

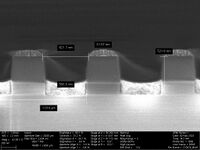

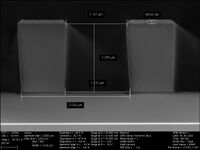

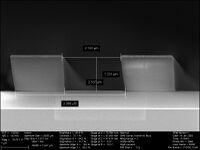

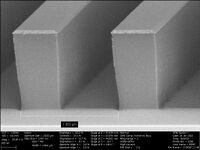

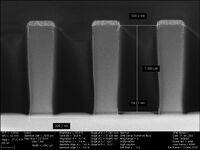

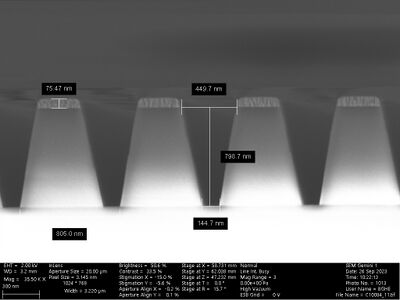

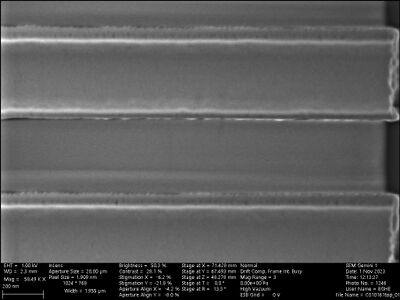

- SiO2 etch with Cr mask on wafer piece on Si carrier 6 min etch, H2:0sccm, C4F8:13sccm He:205sccm O2:20sccm, Pressure:3.6mTorr; platen power 100W, coil power:1200W

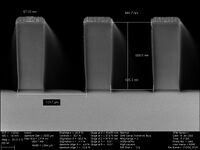

-

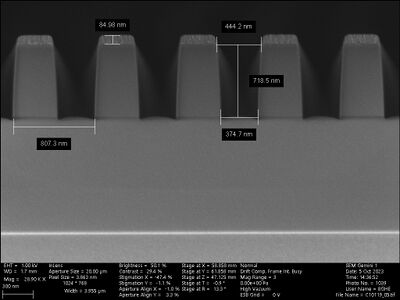

pitch 800 nm

Top 444 nm

bottom 374 nm

height 718 nm

Cr left 85 nm

selectivity 48

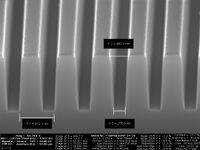

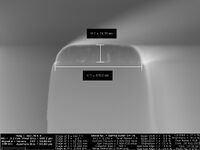

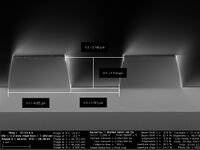

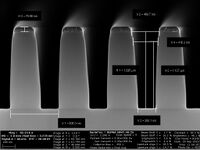

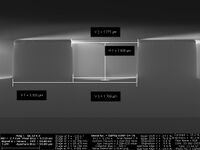

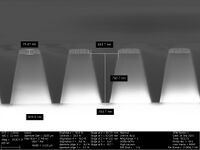

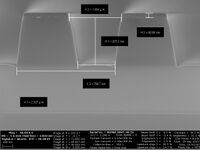

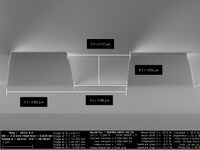

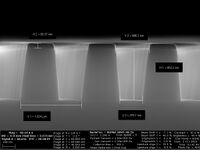

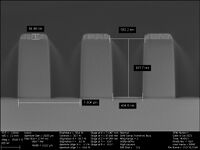

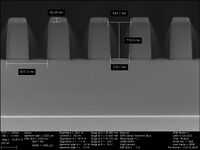

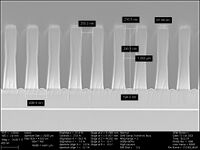

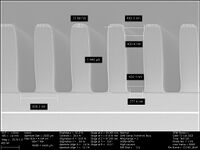

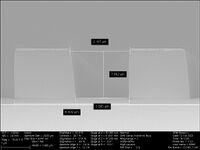

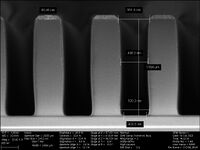

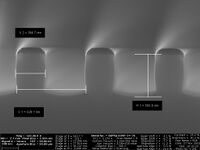

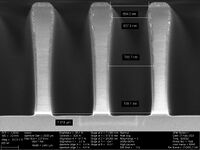

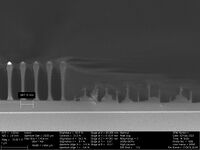

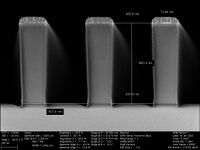

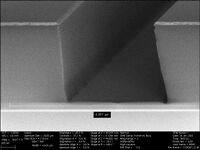

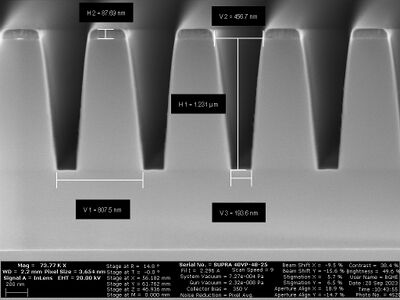

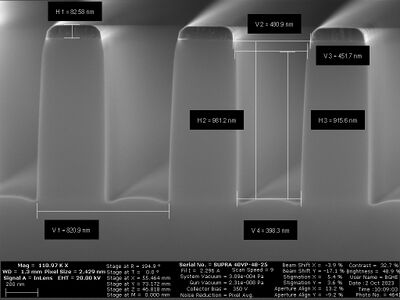

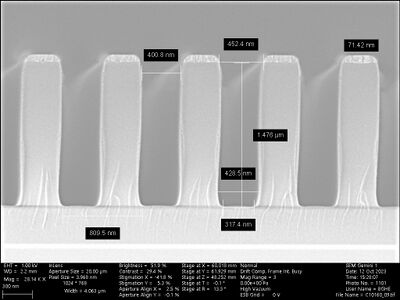

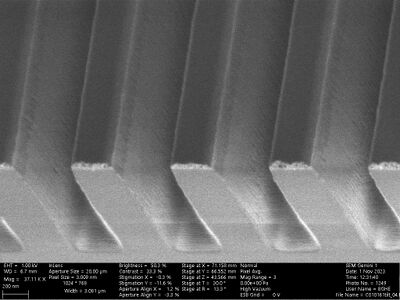

- SiO2 etch with Cr mask on wafer piece on Si carrier 14 min etch (PLEASE DO NOT REPEAT THIS LONG TIME), H2:0sccm, C4F8:13sccm He:205sccm O2:20sccm, Pressure:3.6mTorr; platen power 100W, coil power:1200W

- SiO2 etch with Cr mask on wafer piece on Si carrier 10 min etch, H2:0sccm, C4F8:13sccm He:205sccm O2:20sccm, Pressure:3.6mTorr; platen power 150W, coil power:1800W

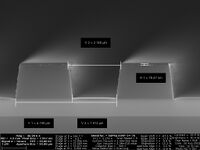

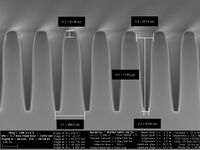

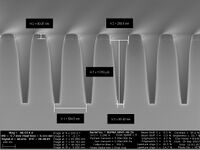

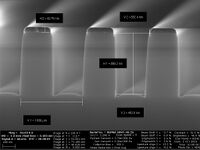

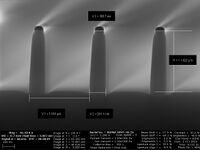

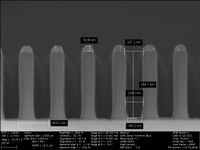

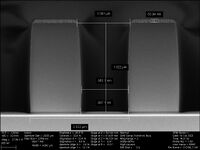

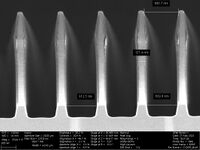

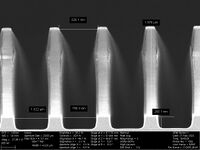

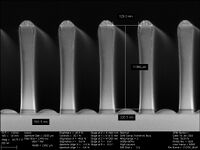

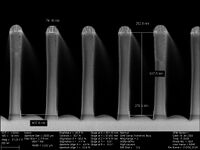

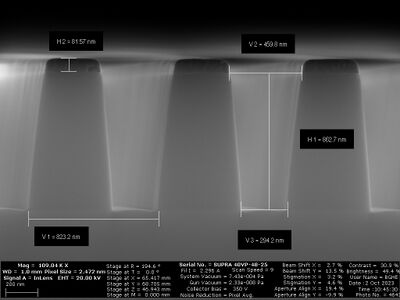

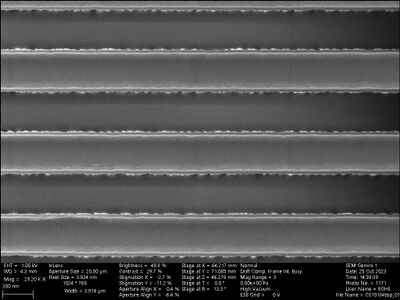

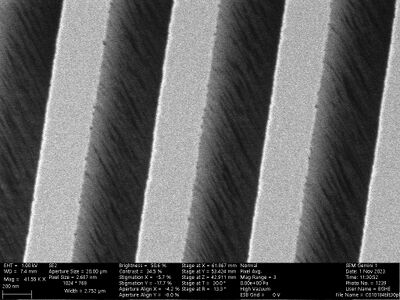

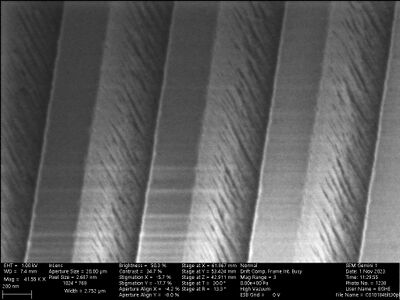

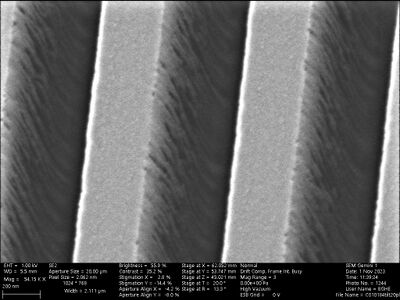

- SiO2 etch with Cr mask on wafer piece on Si carrier 14 min etch, EM:0/0 H2:0sccm, C4F8:13sccm He:205sccm O2:20sccm, Pressure:3.9mTorr; platen power 100W, coil power:1200W, the mask is removed by plasma ashing on top view and tilted view

-

tilt 30 degrees

-

tilt 30 degrees

-

tilt 20 degrees

-

tilt 20 degrees