Specific Process Knowledge/Etch/ICP Metal Etcher: Difference between revisions

Appearance

New page: ==Etching of nanostructures in silicon using the ICP Metal Etcher== === s === Two recipes have been optimized for the ASE. Their specification is on a 10 % etch load wafer with trenches... |

No edit summary |

||

| Line 2: | Line 2: | ||

{| border="2" cellpadding="2" cellspacing="1" | {| border="2" cellpadding="2" cellspacing="1" | ||

| Line 41: | Line 27: | ||

! rowspan="6" align="center"| Main | ! rowspan="6" align="center"| Main | ||

| Gas | | Gas | ||

| | | HBr 20 sccm | ||

|- | |- | ||

| Pressure | | Pressure | ||

| Line 47: | Line 33: | ||

|- | |- | ||

| Power | | Power | ||

| | | 900 W CP, 50 W PP | ||

|- | |- | ||

| Temperature | | Temperature | ||

| Line 56: | Line 42: | ||

|- | |- | ||

| Time | | Time | ||

| | | ? secs | ||

|- | |- | ||

|} | |} | ||

ER 200 nm/min, 3:1 over resist. Vertical profile. To improve selectivity to oxide under-layers you can add a small amount of O2 ( e.g 2 sccm if the MFC is small enough). This should not give an undercut. | |||

<gallery caption="Standardization images of the shallolr recipe" widths="300px" heights="300px" perrow="2"> | <gallery caption="Standardization images of the shallolr recipe" widths="300px" heights="300px" perrow="2"> | ||

Revision as of 15:10, 23 February 2011

Etching of nanostructures in silicon using the ICP Metal Etcher

| Break | Gas | Cl2 20 sccm |

|---|---|---|

| Pressure | 2 mTorr, Strike 3 secs @ 5 mTorr | |

| Power | 600 W CP, 200 W PP | |

| Temperature | 20 degs | |

| Hardware | 100 mm Spacers | |

| Time | 15 secs | |

| Main | Gas | HBr 20 sccm |

| Pressure | 2 mTorr, Strike 3 secs @ 5 mTorr | |

| Power | 900 W CP, 50 W PP | |

| Temperature | 20 degs | |

| Hardware | 100 mm Spacers | |

| Time | ? secs |

ER 200 nm/min, 3:1 over resist. Vertical profile. To improve selectivity to oxide under-layers you can add a small amount of O2 ( e.g 2 sccm if the MFC is small enough). This should not give an undercut.

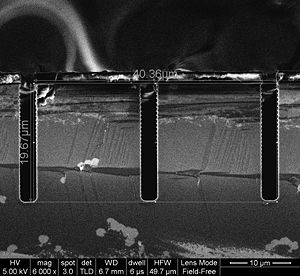

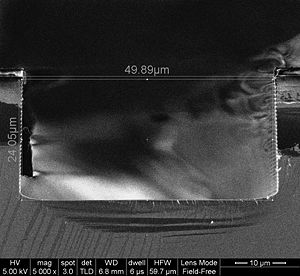

- Standardization images of the shallolr recipe

-

The profile of a 2 m trench

-

The profile of a 50 m trench