Specific Process Knowledge/Lithography/EBeamLithography/Cassettes: Difference between revisions

| Line 23: | Line 23: | ||

== Coordinate system == | == Coordinate system == | ||

When placing a substrate in a cassette it is essential to know the relation between the cassette coordinate system and the design coordinate system. On wafer cassettes this is very obvious as they have a flat pin where the flat of the wafer will sit. On chip cassettes the substrate can however be placed at any rotation and hence the exposed pattern can end up upside down if one does not pay attention to this. | When placing a substrate in a cassette it is essential to know the relation between the cassette coordinate system and the design coordinate system. On wafer cassettes this is very obvious as they have a flat pin where the flat of the wafer will sit. On chip cassettes the substrate can however be placed at any rotation and hence the exposed pattern can end up upside down if one does not pay attention to this. The pattern coordinate system x' and y' is illustrated below. Notice that the is when the cassette is viewed from the front side with the hook placed to the right. | ||

{| style="border: none; border-spacing: 0; margin: 1em auto; text-align: center;" | {| style="border: none; border-spacing: 0; margin: 1em auto; text-align: center;" | ||

Revision as of 13:45, 8 March 2023

JEOL 9500 cassette specifications page

General information

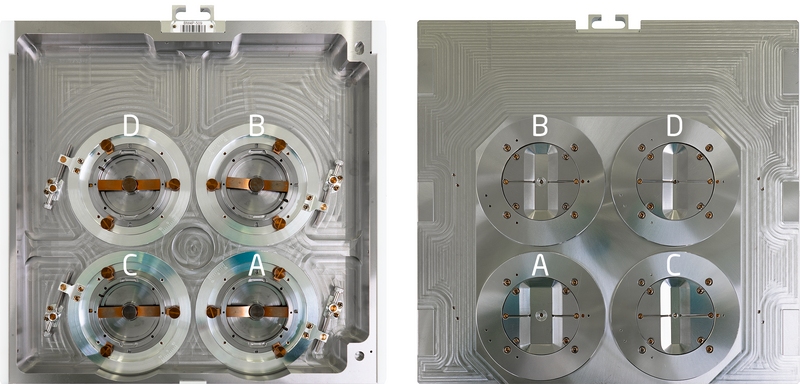

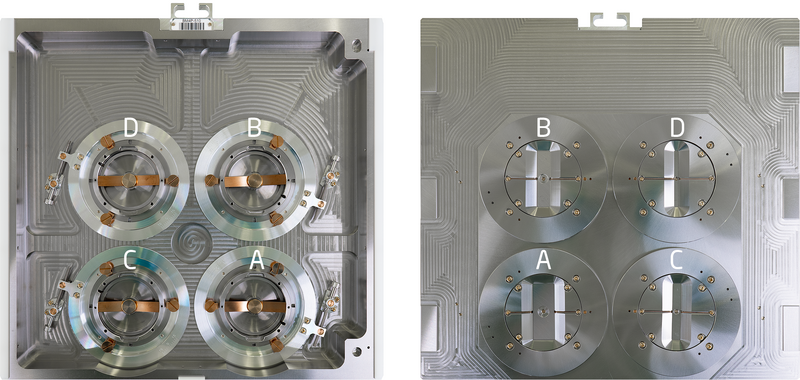

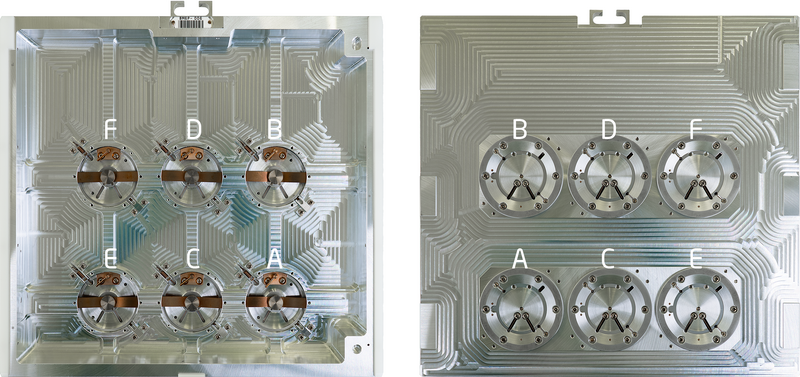

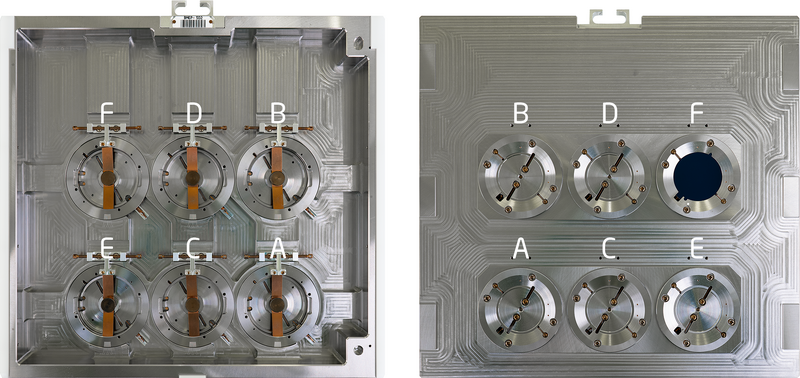

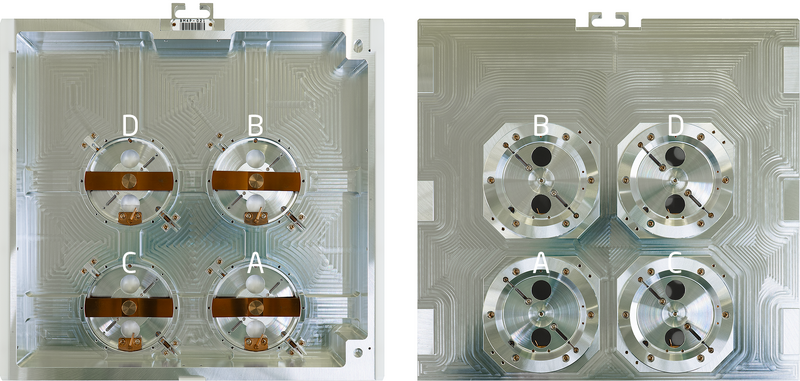

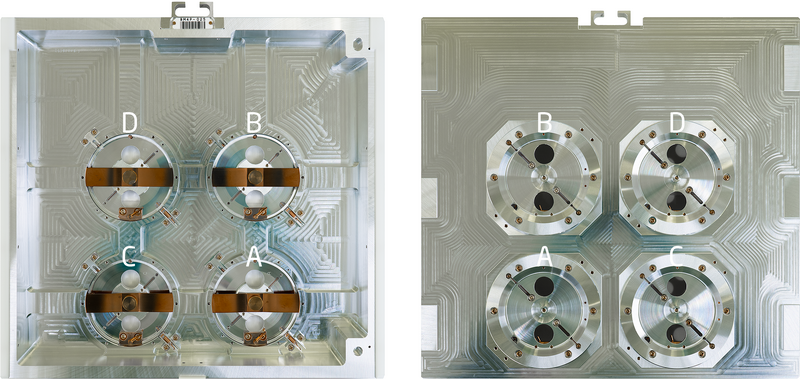

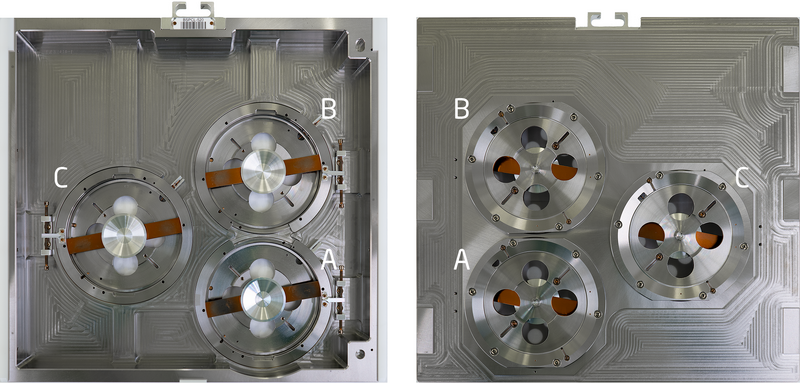

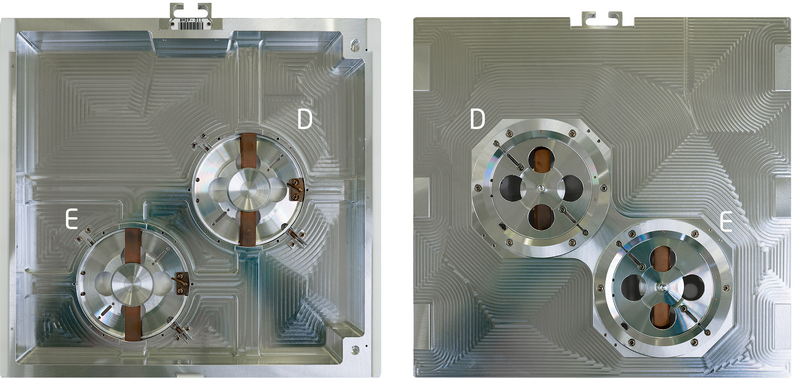

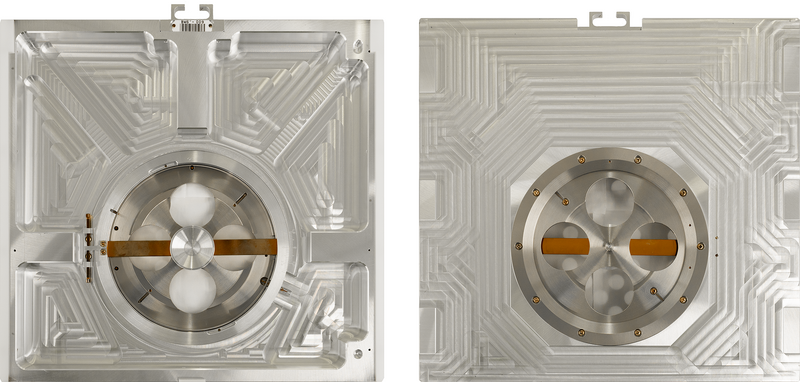

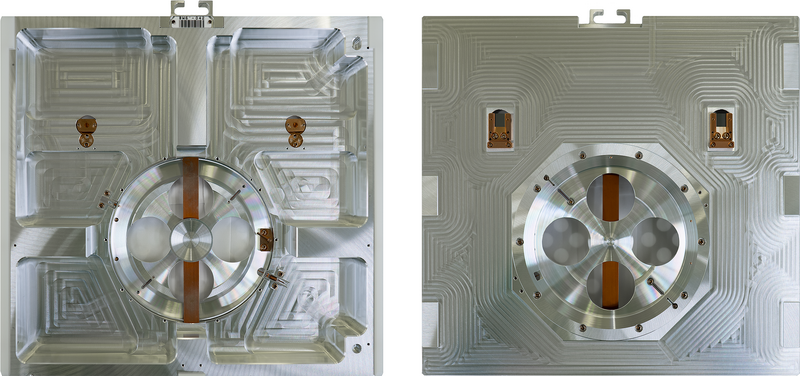

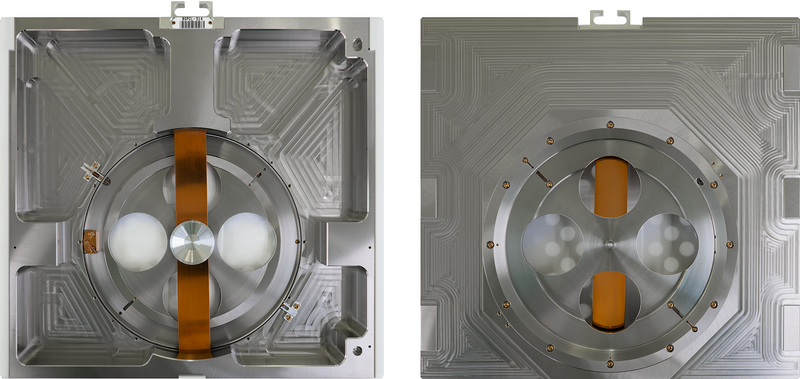

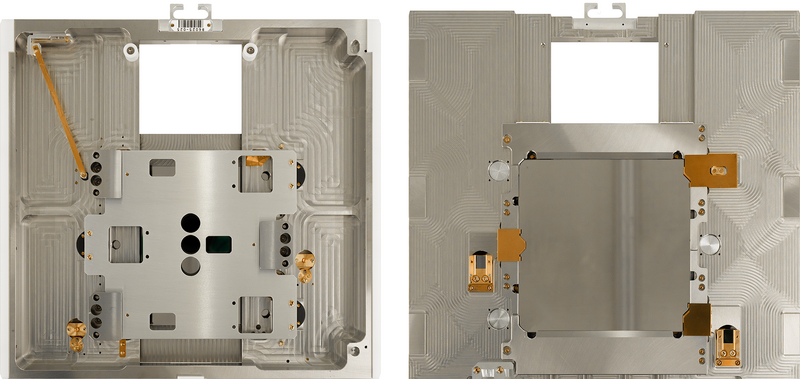

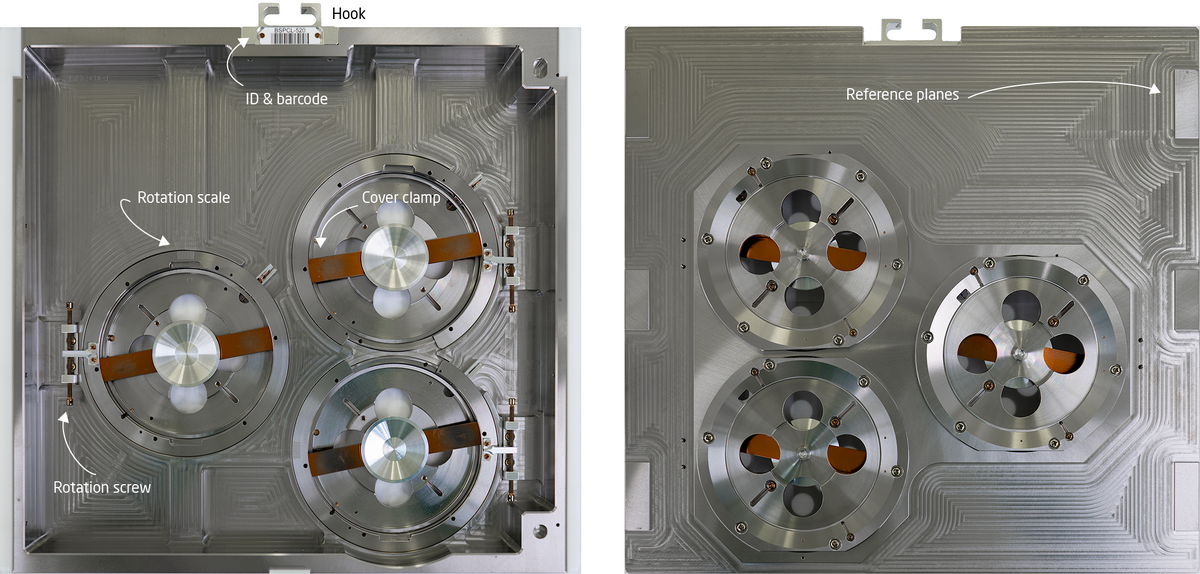

Wafer cassettes are available for 2", 4", 6" and 8" wafers. Wafers must be intact, i.e. fractions of wafers can not be exposed in these cassettes. Cassettes dedicated chip exposure are also available. While cassettes are individually adapted to a specific substrate type they naturally share a set of features as illustrated below.

- The front side has six reference planes. One should avoid touching these to preserver them as clean and scratch free as possible.

- One should also avoid touching the hook.

- On the back side each cassettes has a unique ID and barcode. The barcode is read by the cassette transfer system.

- Substrates are held in place by a cover ring that locks with a copper spring clamp. To unlock a cover simply press down on the copper clamp and turn to the open position.

- Most cassettes have a set screw that can be used to precisely rotate the entire substrate slot. This is mostly used for alignment on the pre-aligner.

- Cassettes with a rotation set screw also has a rotation scale.

- Some cassettes have engraved slot ID's

Cassettes are either made in aluminium or titanium. The thermal expansion coefficient of titanium is about one third of that of aluminium. Hence thermal drift is reduced on titanium cassettes.

|

|

Back side (left )and front side view (right) of the 4" wafer titanium cassette (BSPCL-520). |

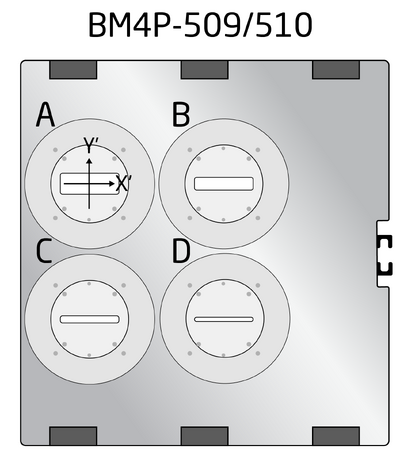

Coordinate system

When placing a substrate in a cassette it is essential to know the relation between the cassette coordinate system and the design coordinate system. On wafer cassettes this is very obvious as they have a flat pin where the flat of the wafer will sit. On chip cassettes the substrate can however be placed at any rotation and hence the exposed pattern can end up upside down if one does not pay attention to this. The pattern coordinate system x' and y' is illustrated below. Notice that the is when the cassette is viewed from the front side with the hook placed to the right.

|

|

Coordinate system is regular orientation when cassette is viewed from the front and hook placed to the right. |