Specific Process Knowledge/Etch/DRIE-Pegasus/Pegasus-4/Barc Etch: Difference between revisions

Appearance

No edit summary |

|||

| Line 1: | Line 1: | ||

==Barc etch with O2== | ==Barc etch with O2== | ||

{{CC-bghe2}}''June 2020'' | {{CC-bghe2}}, ''June 2020'' | ||

===Sample=== | ===Sample=== | ||

*6" Si | *6" Si | ||

Revision as of 11:23, 3 February 2023

Barc etch with O2

Unless otherwise stated, all content in this section was done by Berit Herstrøm, DTU Nanolab, June 2020

Sample

- 6" Si

- 2µm SiO2 from C1

- 90nm barc

- 907 nm UVN 2030-0,5

- Reticle: Pegreticle

- Dose: 200 J/m2

Pegasus 4 settings

- Recipe: Barc O2

- With 30 mm spacers

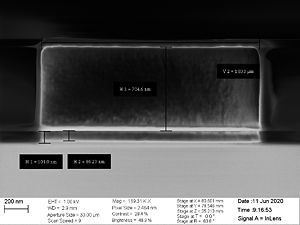

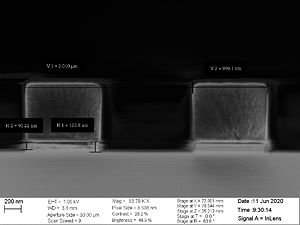

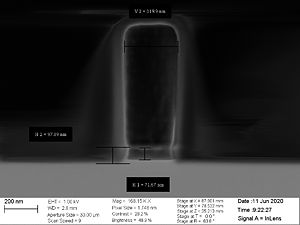

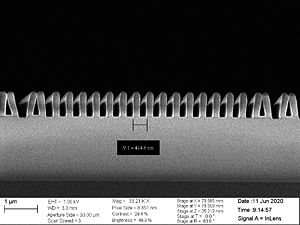

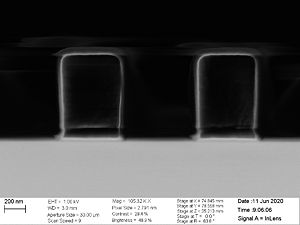

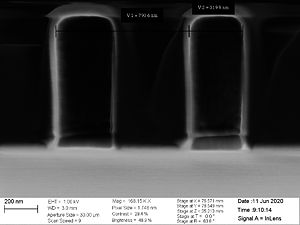

SEM images after barc etching

- C06207_02 Barc O2 30s

-

50% load, 4000 nm pitch, barc has been etched with a little undercut

-

50% load, 2000 nm pitch, barc has been etched with a little undercut

-

75% load, 1600 nm pitch, barc has been etched with a little undercut

-

50% load, 400 nm pitch, barc has been etched with a little undercut expect where the lines have collided

-

50% load, 1300 nm pitch

-

50% load, 800 nm pitch