Specific Process Knowledge/Lithography/5214E: Difference between revisions

| Line 18: | Line 18: | ||

*Reversal bake time: 60-120 s | *Reversal bake time: 60-120 s | ||

*Flood exposure: 200-500 mJ/cm<sup>2</sup> | *Flood exposure: 200-500 mJ/cm<sup>2</sup> | ||

If 5214E is baked after exposure, the exposed resist will cross-link, making it insoluble in the developer. This is called the "Reversal bake", or sometimes the post-exposure bake. The reversal bake activates cross-linking of the exposed areas, which "reverses" the polarity of the design. | If 5214E is baked after exposure, the exposed resist will cross-link, making it insoluble in the developer. This is called the "Reversal bake", or sometimes the post-exposure bake. The reversal bake activates cross-linking of the exposed areas, which "reverses" the polarity of the design. | ||

Revision as of 14:52, 30 January 2023

Resist description

AZ 5214E is a positive UV photoresist with image reversal capability. It is considered to have good adhesion when wet etching.

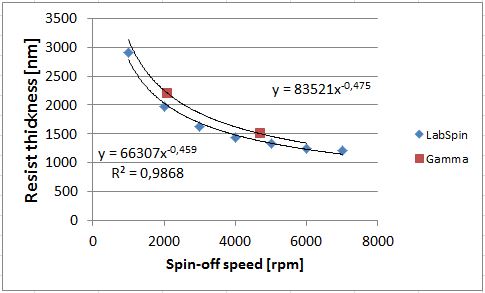

Spin coating

Typical spin parameters:

- Spin off: 30-60 s

- Soft bake: 60s @ 90°C

Image reversal

Typical image reversal parameters:

- Reversal bake temperature: 110°C

- Reversal bake time: 60-120 s

- Flood exposure: 200-500 mJ/cm2

If 5214E is baked after exposure, the exposed resist will cross-link, making it insoluble in the developer. This is called the "Reversal bake", or sometimes the post-exposure bake. The reversal bake activates cross-linking of the exposed areas, which "reverses" the polarity of the design.

If the substrate is flood exposed after the reversal bake, the previously unexposed areas become soluble, and will be removed in the subsequent development. The reversal procedure effectively makes AZ 5214E a negative resist.

The image reversal process greatly increases the sensitivity of AZ 5214E, and the dose of the image exposure is a critical parameter, especially if negative angled resist sidewalls are desired.

Half dose of the normal, positive process is a good starting point for optimization. Similarly, the reversal bake is also a critical step, and must be tightly controlled in order to achieve consistent results. If negative sidewalls are desired, 60-120s at 110°C is recommended (as well as a resist thickness above 2 µm), but if straight sidewalls are desired, 60-120s at 120°C can be used.

The flood exposure, on the other hand, is uncritical, and 2-5 times the normal positive process dose is generally used.

Development

Development speed:

- Puddle development in 2.38% TMAH (AZ 726 MIF): ~2 µm/min