Specific Process Knowledge/Back-end processing/Disco Saw: Difference between revisions

| Line 132: | Line 132: | ||

===Comparing dicing parameters for different materials '''DAD 321'''=== | ===Comparing dicing parameters for different materials '''DAD 321'''=== | ||

Do not mix blades for the DAD 321 with the blades for the DAD 3241. They have different outer diameters | |||

{| border="2" cellspacing="0" cellpadding="4" align="center" | {| border="2" cellspacing="0" cellpadding="4" align="center" | ||

| Line 161: | Line 163: | ||

This leaves 125µm uncut since blue tape is 75µm.<br> | This leaves 125µm uncut since blue tape is 75µm.<br> | ||

It is possible to cut through the sample. | It is possible to cut through the sample. | ||

|-valign="top" | |||

|'''Max. sample thickness''' | |||

|1.5 mm | |||

|2.0 mm | |||

|- | |||

|} | |||

===Comparing dicing parameters for different materials '''DAD 3241'''=== | |||

Do not mix blades for the DAD 321 with the blades for the DAD 3241. They have different outer diameters | |||

{| border="2" cellspacing="0" cellpadding="4" align="center" | |||

! | |||

!Silicon | |||

!Other materials | |||

|- valign="top" | |||

|'''Bladetype''' | |||

|HUB Blade | |||

|ASK! (HUBless) | |||

|-valign="top" | |||

|'''Blade width''' | |||

|50 µm | |||

|ask | |||

|-valign="top" | |||

|'''Cutlinewidth''' | |||

|50 µm | |||

|ask | |||

|-valign="top" | |||

|'''Recommended feed speed''' | |||

|Up to 40 mm/sec | |||

|ask | |||

|-valign="top" | |||

|'''Recommended dice depth''' | |||

|We usually cut all way through the wafer with a blade height of 50µm (preferred).<br> | |||

|ask! | |||

|-valign="top" | |-valign="top" | ||

|'''Max. sample thickness''' | |'''Max. sample thickness''' | ||

Revision as of 10:52, 19 July 2022

Feedback to this page: click here

Disco Automatic dicing saw, model DAD321 (old) and DAD3241 (new 2021)

The dicers feature versatile processing capabilities, compact designs, and high precision and reliability. Users perform workpiece loading, alignment, and unloading manually.

The dicers at DTU Nanolab is placed in room 157 on the first floor in bldg. 346. Please notice that this is not a cleanroom and that the dicing process is very dirty.

In general it is not allowed to bring back your samples into the Cleanroom. You need approval from DTU Nanolab staff to do this. Your samples have to be thoroughly cleaned in the gowning area and get a Piranha cleaning. You will only be allowed to use a limited number of tools for the processing after dicing.

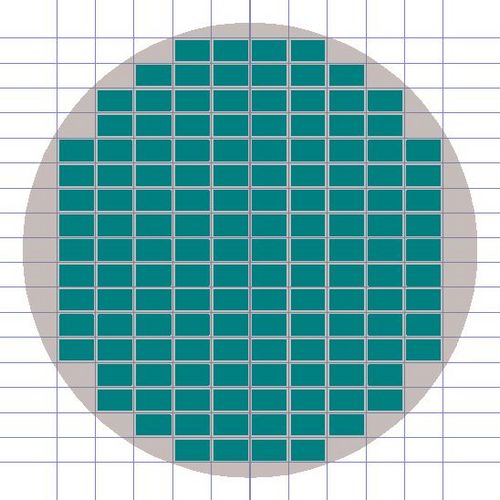

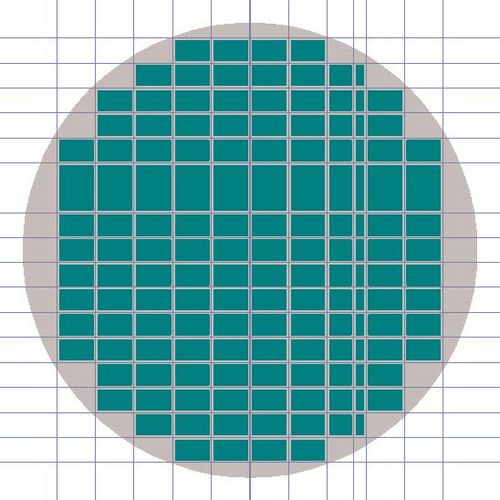

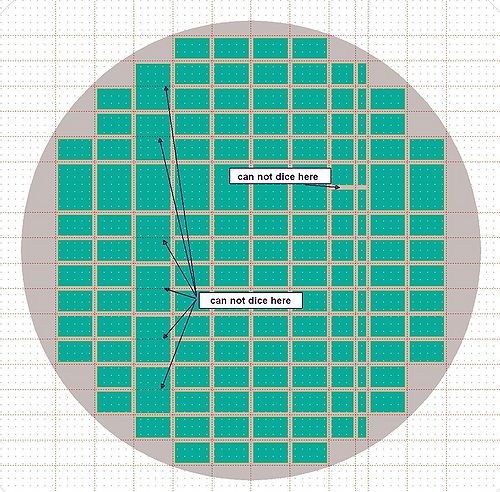

Please consider your layout of dies on your wafer. The dicer can only cut straight lines across the wafer and you can not end a line in the middle of the wafer. Please see the illustrations for a good and a bad design.

| GOOD design - simple | GOOD design - complex | BAD design | |

|

|

|

|

| GOOD design - simple | GOOD design - complex | BAD design |

The user manual, user APV, technical information and contact information can be found in LabManager:

DAD 321 Saw in LabManager

DAD 3241 Saw in LabManager

Process information

- Comparing dicing parameters for different materials

- Images of diced samples

- Dicing work sheet: Dicing.doc Fill out before requesting dicing.

Overview of the performance Disco DAD321 Dicer

| Purpose | Dicer |

DAD 321 (old)| |

DAD 3241 (new 2021)| |

|---|---|---|---|

| Purpose | Equipment for dicing out samples |

|

|

| Performance | X-axis cutting range |

192 mm |

2xx mm |

| X-axis cut speed |

0.1 - 300 mm/sec |

??? mm/sec | |

| Y-axis cutting range |

162 mm |

2xx mm | |

| Y-axis index step |

0.0002 mm |

0.0002 mm | |

| Y-axis single error |

0.003 or less |

0.003 or less | |

| Hardware settings | Maximum blade size |

ø76.2 mm |

ø76.2 mm |

| Substrates | Substrate size |

up to 6" |

up to 8" |

| Layers that can't be diced |

|

|

Comparing dicing parameters for different materials DAD 321

Do not mix blades for the DAD 321 with the blades for the DAD 3241. They have different outer diameters

| Silicon | Pyrex or bonded Si/Pyrex | |

|---|---|---|

| Bladetype | HUB Blade ZH05 (27HEEF) | HUBless Blade B1A862 |

| Blade width | 50 µm | 150 µm |

| Cutlinewidth | 60 µm | 180 - 200 µm |

| Recommended feed speed | Up to 20 mm/sec | Up to 2 mm/sec (0.5 mm/sec) |

| Recommended dice depth | Set blade height to 200µm (preferred). This leaves 125µm uncut since blue tape is 75µm. It is possible to cut through the sample. |

Do not cut deeper than 500 µm in each pass (for fused Silica and SiC 200 µm). If you have thicker wafers then use several passes decreasing the blade height for each pass. |

| Max. sample thickness | 1.5 mm | 2.0 mm |

Comparing dicing parameters for different materials DAD 3241

Do not mix blades for the DAD 321 with the blades for the DAD 3241. They have different outer diameters

| Silicon | Other materials | |

|---|---|---|

| Bladetype | HUB Blade | ASK! (HUBless) |

| Blade width | 50 µm | ask |

| Cutlinewidth | 50 µm | ask |

| Recommended feed speed | Up to 40 mm/sec | ask |

| Recommended dice depth | We usually cut all way through the wafer with a blade height of 50µm (preferred). |

ask! |

| Max. sample thickness | 1.5 mm | 2.0 mm |

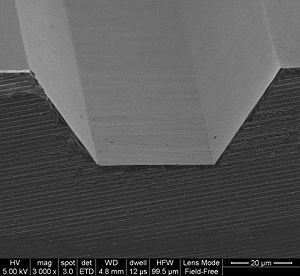

Images of diced samples