Specific Process Knowledge/Lithography/ARN8200: Difference between revisions

Appearance

| Line 28: | Line 28: | ||

|- | |- | ||

|-style="background:WhiteSmoke; color:black" | |-style="background:WhiteSmoke; color:black" | ||

|AR-N8200.06 | |AR-N8200.06 | ||

|LabSpin | |LabSpin 2, 4000 rpm for 60s, softbake 10 min @ 150 degC | ||

| | |JBX9500, 60 nA, doses 100-1600 µC/cm2, 150 µm x 300 µm rectangles | ||

| | |Labspin 2 hotplate, 130, 150, 160 or 170 degC for 10 min | ||

| | |EBL development fumehood, 60 sec development in AR300-47:DIW (1:1), 30 sec rinse in DIW, nitrogen gun dry | ||

|- | |- | ||

Revision as of 09:32, 17 March 2022

AR-N 8200

AR-N 8200 is a negative E-beam resist from Allresist, it is also known as "Medusa 82". A product presentation from Allresist is available here AR-N8200 presentation.

Allresist also provides these processing guidelines.

Contrast curve

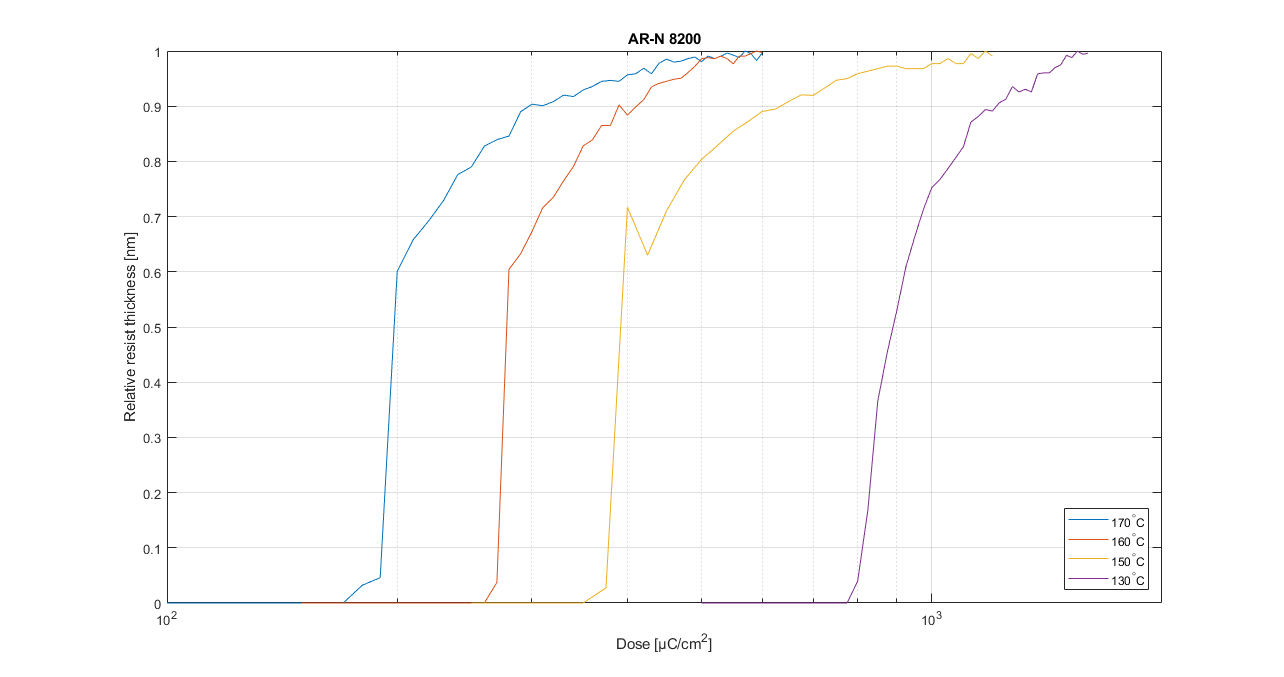

Exposure dose for AR-N 8200 is very dependent on Post Exposure Bake (PEB) temperature. A contrast curve for four different PEB processes were obtained with the following process parameters.

| AR-N 8200 Contrast Curve, Processed by THOPE, FEB 2022 | ||||

|---|---|---|---|---|

| Resist | Spin Coat | E-beam exposure | PEB | Development |

| AR-N8200.06 | LabSpin 2, 4000 rpm for 60s, softbake 10 min @ 150 degC | JBX9500, 60 nA, doses 100-1600 µC/cm2, 150 µm x 300 µm rectangles | Labspin 2 hotplate, 130, 150, 160 or 170 degC for 10 min | EBL development fumehood, 60 sec development in AR300-47:DIW (1:1), 30 sec rinse in DIW, nitrogen gun dry |

Spin coating Labspin 2