Specific Process Knowledge/Back-end processing/Disco Saw: Difference between revisions

Appearance

No edit summary |

|||

| Line 90: | Line 90: | ||

|1.5 mm | |1.5 mm | ||

|2.0 mm | |2.0 mm | ||

|- | |- | ||

|} | |} | ||

Revision as of 09:49, 20 February 2010

Disco Automatic dicing saw, model DAD321

The dicer feature versatile processing capabilities, compact designs, and high precision and reliability. Users perform workpiece loading, alignment, and unloading manually.

The dicer at DANCHIP is placed in room 157 on the first floor in bldg. 346. Please notice that this is not a cleanroom and that the dicing process is very dirty. Think about how to clean your samples if you want to bring them back in the cleanroom.

Overview of the performance Disco DAD321 Dicer

| Purpose | Equipment for dicing out samples |

|

|---|---|---|

| Performance | X-axis cutting range |

192 mm |

| X-axis cut speed |

0.1 - 300 mm/sec | |

| Y-axis cutting range |

162 µm | |

| Y-axis index step |

0.0002 mm | |

| Y-axis single error |

0.003 or less | |

| Hardware settings | Maximum blade size |

ø76.2 mm |

| Substrates | Substrate size |

up to 6" |

| Layers that can't be diced |

|

Comparing dicing parameters for different materials

| Silicon | Pyrex or bonded Si/Pyrex | |

|---|---|---|

| Bladetype | HUB Blade ZH05 (27HEEF) | HUBless Blade B1A862 |

| Cutlinewidth | 60 µm | 150 µm |

| Recommended feed speed | Up to 5 mm/sec | Up to 2 mm/sec (0.5 mm/sec) |

| Recommended dice depth | Leave 200 µm uncut. It's possible to cut through the sample. | Leave 200 µm uncut. It's possible to cut through the sample. |

| Max. sample thickness | 1.5 mm | 2.0 mm |

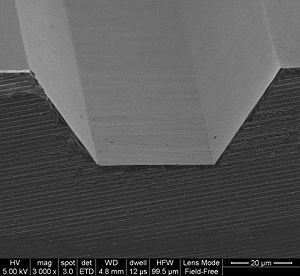

Images of diced samples