Specific Process Knowledge/Etch/KOH Etch/ProcessInfo: Difference between revisions

| Line 68: | Line 68: | ||

Nanolabs standard solution in the KOH baths has a concentration of 28 wt% and is mixed of 1 liter of a premade 50wt% KOH solution to 1.2 l of water. | Nanolabs standard solution in the KOH baths has a concentration of 28 wt% and is mixed of 1 liter of a premade 50wt% KOH solution to 1.2 l of water. | ||

Revision as of 14:44, 7 September 2021

Feedback to this page: click here

QC

Quality Control (QC) for the KOH Si etching baths.

| Quality Control (QC) for Si Etch 01, and Si Etch 02 | ||||||||||||||||||||||||||||||||

|

Mixing KOH

Nanolabs standard solution in the KOH baths has a concentration of 28 wt% and is mixed of 1 liter of a premade 50wt% KOH solution to 1.2 l of water.

If you use the 50wt% premade KOH solution you can calculate the amount of solution X you need to add 1 liter of water to achieve a concentration of Y wt% by:

where 1.509 g/ml is the density of a 50wt% solution KOH at 20 °C.

So for a 10 wt% solution you will need 165 ml of KOH (50wt%) to 1 l of water.

Backside protection

It is possible to protect the backside of the wafer against the KOH etch using special wafer holder.

Theory

Definition of structures

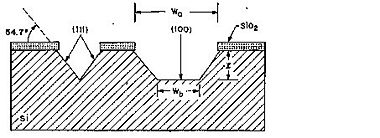

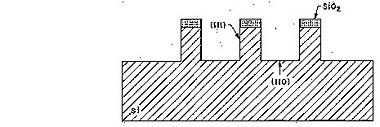

Due to the almost inert (111)-planes it is possible by KOH etching to realize high aspect ratio structures in sigle crytalline silicon using the (111)-planes as sidewalls. In Si(100) these sidewalls are inclined - 54.7o with respect to the (100) surface - whereas in Si(110) the sidewalls are vertical (see figures below).

- Anisotropic wet silicon etch: dependency on crystal orientation

-

Etched profile when etching Si(100).

-

Etched profile when etching Si(110).

For Si(100), the relation between the width of the bottom of the etched groove (Wb) and the width of the opening (Wo) at the wafer surface in a groove etched to the depth l is given by:

Definition of <110> alignment structures

The etch rate dependence on the crystallographic planes can be used to determine the <110> crystal directions with high precision (better than +/- 0.05 o). A fast method for doing this, using the symmetric under-etching behavior around but not at the <110>-directions, was described by Vangbo and Bäcklund in J. Micromech. Microeng.6 (1996), 279-284. High-precision control of the <110>-direction during alignment can be necessary in order to control the dimensions of KOH-etched structures (e.g. precise control of V-groove dimensions). A dedicated mask (MASK NAME) has been designed for this purpose.

Etch rates: Empirical formula (Seidl et al)

The following empirical formula can be used for concentrations in the range of 10-60 wt%:

R = k0 [H2O]4 [KOH]0.25 e-Ea/kT,

where k0 = 2480 µm/hr (mol/l)-4.25, Ea = 0.595 eV for Si(100)

and k0 = 4500 µm/hr (mol/l)-4.25, Ea = 0.60 eV for Si(110)