Specific Process Knowledge/Etch/DRIE-Pegasus/Pegasus-4/SiO2 Etch: Difference between revisions

Appearance

| Line 3: | Line 3: | ||

/Berit Herstrøm bghe@dtu.dk (Nanolab) | /Berit Herstrøm bghe@dtu.dk (Nanolab) | ||

*Click here for more results on the process development on SiO2 etch with DUV resist mask | *[[/SiO2 etch with resist mask|Click here for more results on the process development on SiO2 etch with DUV resist mask]] | ||

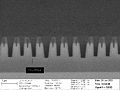

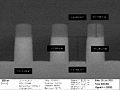

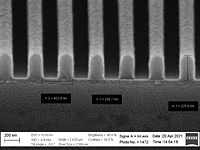

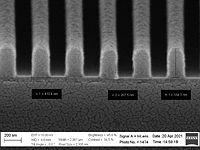

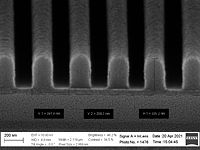

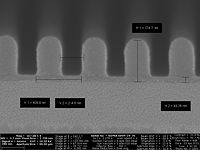

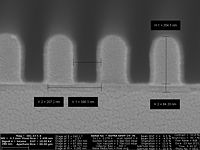

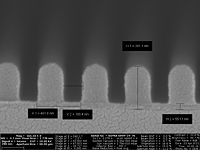

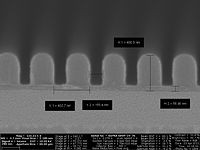

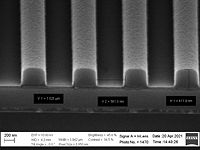

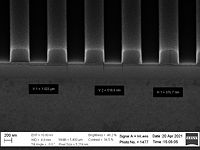

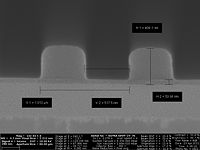

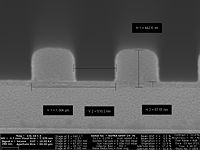

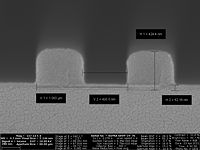

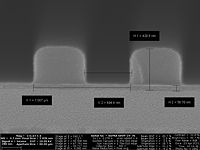

<gallery caption="Recipe name: SiO2_res_10, Recipe no. 10: C06445_02 coil_2500W, platen:300W, He/C4F8= 17.5, C4F8/H2=1, Pressure:8.8mTorr, C4F8:25.6sccm, He:448.7sccm, H2:25.6sccm, 3:56 min " perrow="4"> | <gallery caption="Recipe name: SiO2_res_10, Recipe no. 10: C06445_02 coil_2500W, platen:300W, He/C4F8= 17.5, C4F8/H2=1, Pressure:8.8mTorr, C4F8:25.6sccm, He:448.7sccm, H2:25.6sccm, 3:56 min " perrow="4"> | ||

Revision as of 14:39, 27 April 2021

SiO2 Etch using resist as masking material

I am in the process of doing some development of a SiO2 etch. So far I have found this fairly good recipe. For now it is the standard SiO2 etch recipes but I might change the "Standard recipe" a a later time if I find a better one. You are welcome to contact me see more result. I will add them to Labadviser at a later time. /Berit Herstrøm bghe@dtu.dk (Nanolab)

- Recipe name: SiO2_res_10, Recipe no. 10: C06445_02 coil_2500W, platen:300W, He/C4F8= 17.5, C4F8/H2=1, Pressure:8.8mTorr, C4F8:25.6sccm, He:448.7sccm, H2:25.6sccm, 3:56 min

-

0.4µ/0.2µ

Bad lithography -

0.5/0.25µ

Etch depth: 652 nm

Resist left: 456 nm -

1µ/0.5µ:

Etch depth: 855 nm

Resist left: 487 nm -

2µ/1µ:

Etch depth: 952 nm

Resist left: 487 nm -

4µ/2µ:

Etch depth: 1106 nm

Resist left: 487 nm -

0.8µ/0.2µ

Etch depth: 867 nm

Resist left: 426 nm -

1.0µ/0.25µ:

Etch depth: 893 nm

Resist left: 460 nm -

4µ/1µ:

Etch depth: 1033 nm

Resist left: 473 nm

SiO2 Etch using aSi as masking material

I am now starting up development of SiO2 etch using aSi as masking material.

The samples I use are:

- 6" Si afters with oxide (2µm),

- aSi (~300nm),

- Neg. DUV reist (~60nm barc, ~350 nm resist)

- Reticle: Danchip/Triple-D

- Dose 230 J/m2

First I need to make sure that the resist work for pattering the aSi layer is good. If the resist is not good the final etch will also not be good.

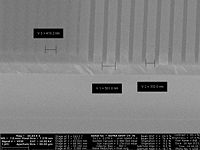

DUV optimization

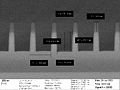

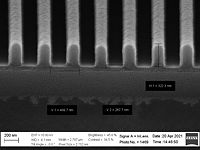

Dose test with the doses (J/m2): 200, 210, 220, 230, 240, 250, 270, 280 The aim was to get good line for 400nm pitch/200nm lines

- 400nm pitch 200 nm lines

-

200 J/m2 400nm/268nm

-

210 J/m2 400nm/239nm

-

220 J/m2 400nm/208nm

-

230 J/m2 400nm/209nm

-

240 J/m2 400nm/215nm

-

250 J/m2 400nm/207nm

-

260 J/m2 400nm/188nm

-

270 J/m2 400nm/155nm

-

280 J/m2 400nm/0nm

- 1000nm pitch 500 nm lines

-

210 J/m2 1000nm/581nm

-

230 J/m2 1000nm/517nm

-

240 J/m2 1000nm/518nm

-

250 J/m2 1000nm/510nm

-

260 J/m2 1000nm/493nm

-

270 J/m2 1000nm/494nm