Specific Process Knowledge/Etch/DRIE-Pegasus/DREM/DREM 3kW 100%: Difference between revisions

Appearance

Created page with "{| border="2" cellpadding="0" cellspacing="0" style="text-align:center;" |- ! rowspan="2" width="40"| Date ! colspan="2" width="120"| Substrate Information ! colspan="4" | Pro..." |

No edit summary |

||

| Line 56: | Line 56: | ||

{| {{table}} | {| {{table}} | ||

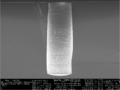

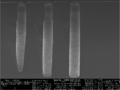

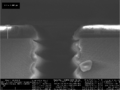

| align="center" style="background:#f0f0f0;"|'''SEM image:''' | | align="center" style="background:#f0f0f0;"|'''SEM image:''' | ||

| align="center" style="background:#f0f0f0;"|'''[http:// | | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S018605a580.png a580]''' | ||

| align="center" style="background:#f0f0f0;"|'''[http:// | | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S018605a582.png a582]''' | ||

| align="center" style="background:#f0f0f0;"|'''[http:// | | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S018605a583.png a583]''' | ||

| align="center" style="background:#f0f0f0;"|'''[http:// | | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S018605a584.png a584]''' | ||

| align="center" style="background:#f0f0f0;"|'''[http:// | | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S018605a586.png a586]''' | ||

| align="center" style="background:#f0f0f0;"|'''[http:// | | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S018605a587.png a587]''' | ||

| align="center" style="background:#f0f0f0;"|'''[http:// | | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S018605a588.png a588]''' | ||

| align="center" style="background:#f0f0f0;"|'''[http:// | | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S018605a589.png a589]''' | ||

| align="center" style="background:#f0f0f0;"|'''[http:// | | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S018605a591.png a591]''' | ||

| align="center" style="background:#f0f0f0;"|'''[http:// | | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S018605a592.png a592]''' | ||

| align="center" style="background:#f0f0f0;"|'''[http:// | | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S018605a593.png a593]''' | ||

|- | |- | ||

| Trench width (um)||250.32||160.36||80.48||40.42||25.42||16.66||10.43||8.38||5.02||2.95||3 | | Trench width (um)||250.32||160.36||80.48||40.42||25.42||16.66||10.43||8.38||5.02||2.95||3 | ||

Revision as of 11:02, 20 March 2020

| Date | Substrate Information | Process Information | Results | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wafer info | Material/ Exposed area | Condi- tioning | Recipe | Wafer ID | Comments | SEM images | Picoscope | Numbers | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 27/11-2019 | Medusa One AZ Mir | Si / 10% | stab-19 TDESC clean5, RF MU runs | nanolab/ vy / DREM / DREM 3kW 100% 120 cycles or 10:0 minutes | S018605 | Process log entry |

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||