Specific Process Knowledge/Etch/DRIE-Pegasus/picoscope: Difference between revisions

Appearance

| Line 13: | Line 13: | ||

|- | |- | ||

! Gas flow (sccm) | ! Gas flow (sccm) | ||

| SF<sub>6</sub> 350 (1.5 s) 550 | | SF<sub>6</sub> 350 (1.5 s), 550 | ||

| C<sub>4</sub>F<sub>8</sub> 200 | | C<sub>4</sub>F<sub>8</sub> 200 | ||

|- | |- | ||

| Line 21: | Line 21: | ||

|- | |- | ||

! Pressure (mtorr) | ! Pressure (mtorr) | ||

| 25 (1.5 s) 150 | | 25 (1.5 s), 150 | ||

| 25 | | 25 | ||

|- | |- | ||

| Line 31: | Line 31: | ||

| 140 (1.5) 45 | | 140 (1.5) 45 | ||

| 0 | | 0 | ||

|- | |- | ||

! Common | ! Common | ||

| colspan="2" | Temperature 20 degs | | colspan="2" | Temperature 20 degs | ||

|- | |- | ||

|} | |} | ||

Revision as of 12:11, 17 March 2020

Process optimization using the Picoscope

The original standard recipes on Pegasus 1 differ in many ways. The second step of one of them is listed below:

| Process A Step 2 parameters | ||

|---|---|---|

| Parameter | Etch | Dep |

| Gas flow (sccm) | SF6 350 (1.5 s), 550 | C4F8 200 |

| Cycle time (secs) | 7.0 | 4.0 |

| Pressure (mtorr) | 25 (1.5 s), 150 | 25 |

| Coil power (W) | 2800 | 2000 |

| Platen power (W) | 140 (1.5) 45 | 0 |

| Common | Temperature 20 degs | |

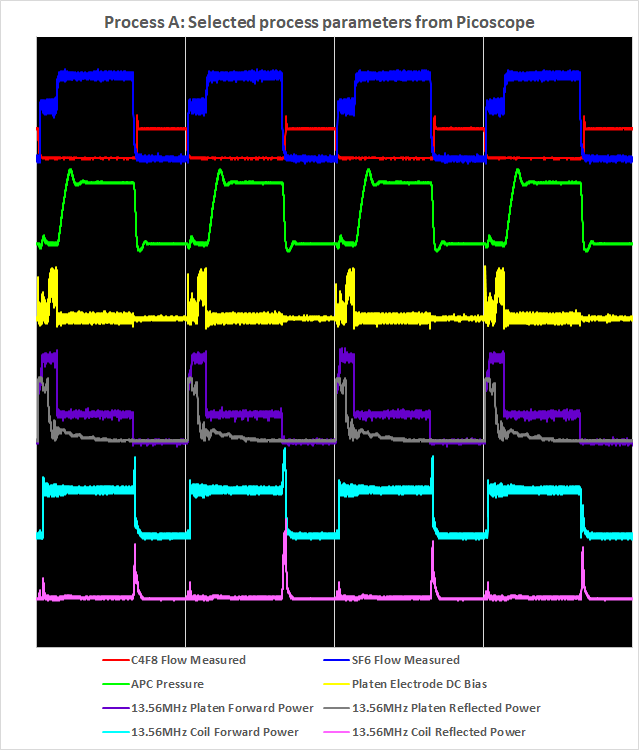

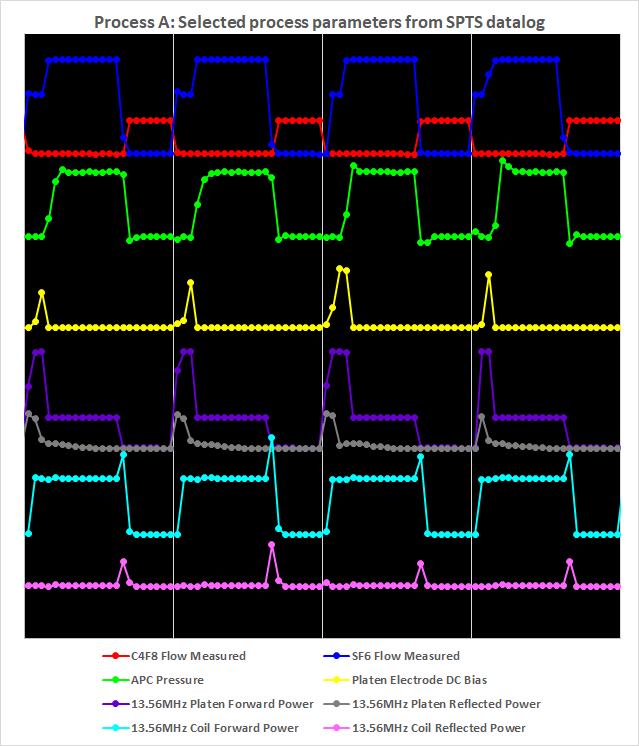

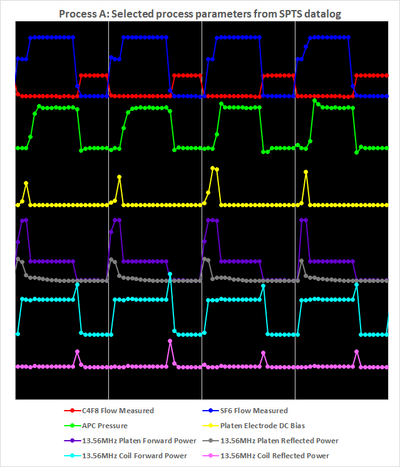

- 4 cycles of Process A

-

Recorded with the SPTS software

-

Recorded with the Picoscope

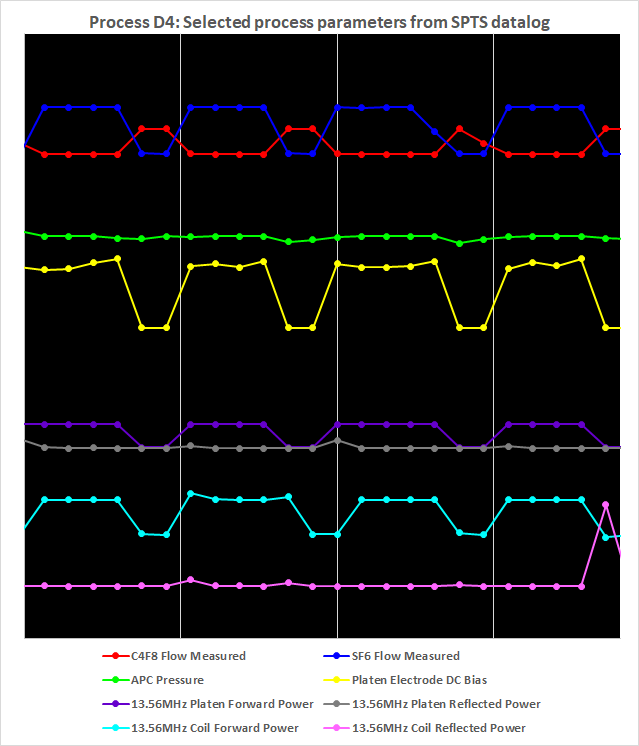

- 4 cycles of Process D4

-

Recorded with the SPTS software

-

Recorded with the Picoscope