Specific Process Knowledge/Lithography/EBeamLithography/High resolution patterning with HSQ: Difference between revisions

No edit summary |

No edit summary |

||

| Line 15: | Line 15: | ||

In most cases the time from taking HSQ out of the fridge to spin coat, and between spin coat and exposure as well as the time between exposure and development impacts on the resolution achieved. | In most cases the time from taking HSQ out of the fridge to spin coat, and between spin coat and exposure as well as the time between exposure and development impacts on the resolution achieved. | ||

It is therefore not recommended to use HSQ as a trainings resist. | It is therefore not recommended to use HSQ as a trainings resist. | ||

/BR | /BR | ||

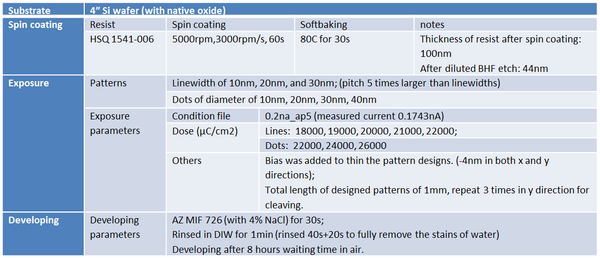

The details of the process is shown below in the table: | The details of the process is shown below in the table: | ||

Revision as of 10:25, 27 January 2020

Feedback to this page: click here

- This work was done by Bingdong Chang and Xiaoli Zhu in 2016;

- This page was edited by Bingdong Chang 23 October 2017.

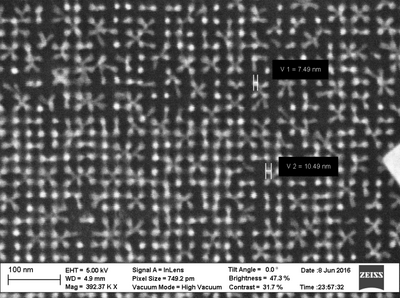

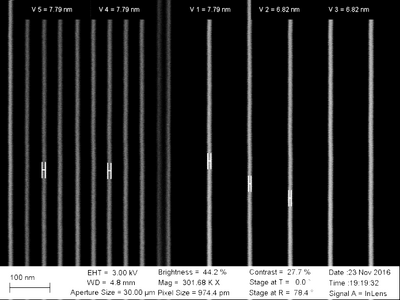

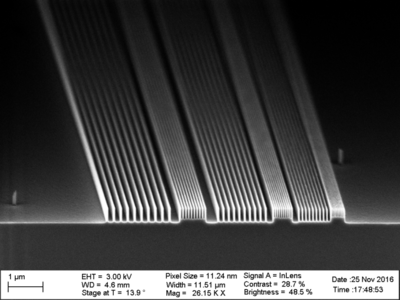

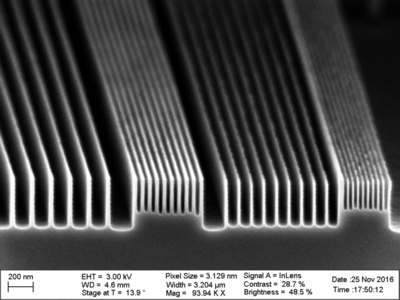

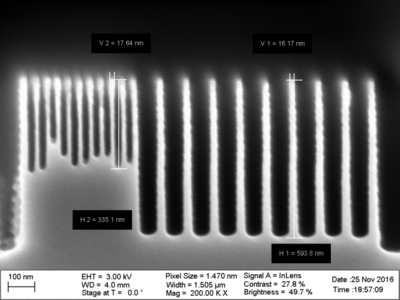

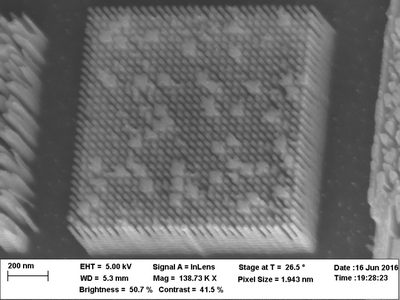

High resolution patterns (sub-10nm dots with 20nm pitch, sub-10nm lines with 50nm pitch) can be patterned with HSQ resist. Some SEM images are shown as below:

- SEM images of high resolution HSQ patterns

-

Dots with sub-10nm diameters

-

Lines with sub-10nm linewidths

In most cases the time from taking HSQ out of the fridge to spin coat, and between spin coat and exposure as well as the time between exposure and development impacts on the resolution achieved. It is therefore not recommended to use HSQ as a trainings resist.

/BR The details of the process is shown below in the table:

- Processing parameters for high resolution HSQ patterning

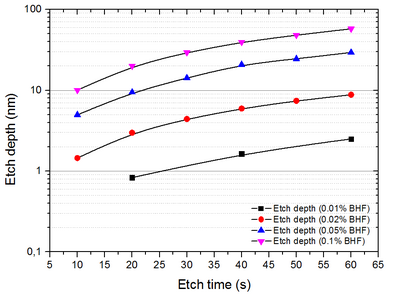

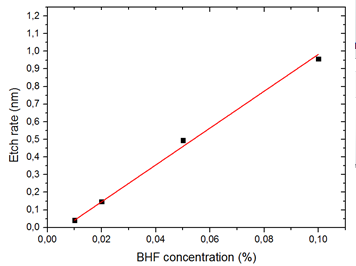

It should be noticed that to reduce the broadening of patterns caused by forward and backward scattered electrons, the HSQ resist was first thinned down to below 50nm using BHF before exposure. PEC could also improve the resolution. The etch rate of HSQ with different concentration of BHF is shown as below.

The details of the process is shown below in the table:

- Etch rate of HSQ (XR-1541 006) with BHF

The patterns were successfully transferred into silicon by dry etching (with ASE, recipe Pxnano2)

- Etch rate of HSQ (XR-1541 006) with BHF

Notice that roughness could be generated during etch by redeposition of HSQ hard mask. For more details, please contact Bingdong Chang (bincha@dtu.dk).