Specific Process Knowledge/Etch/Etching of SU-8: Difference between revisions

No edit summary |

No edit summary |

||

| Line 12: | Line 12: | ||

{| border="2" cellpadding="2" cellspacing="1" style="text-align:center;" | {| border="2" cellpadding="2" cellspacing="1" style="text-align:center;" | ||

|+ '''SU8aniso and SU8iso etches''' by khara@ | |+ '''SU8aniso and SU8iso etches''' by khara@nanolab | ||

|- | |- | ||

! Parameter | ! Parameter | ||

Revision as of 19:15, 25 November 2019

Etching of SU-8

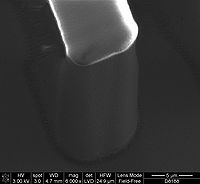

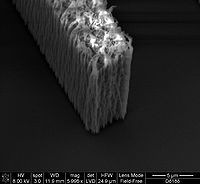

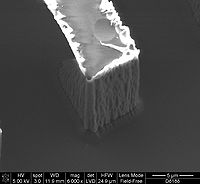

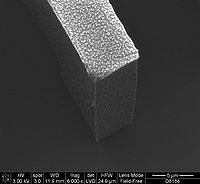

SU-8 can be etched by a oxygen plasma with a small amount of SF6 to remove the antimony present from the photo initiator. Etching of SU-8 has been developed on the ASE and was tested as a mask less reduction of patterns defined by photo lithography. Two processes are available, a high and a low anisotropic etch for use as etching or thinning of structures.

- High anisotropic etch: etch rate ~400nm/min, anisotropy ~0.8

- Low anisotropic etch: etch rate ~170nm/min, anisotropy ~0.3

Recipes in ASE

SU8aniso

The anisotropic SU8aniso etch was design to etch structures in SU-8 with a low roughness of the etched surface, however it has not been tested with any mask material. For a polymeric mask a low selectivity is expected. The etch rate was measured to around 400 nm/min, but will depend on wafer coverage. The surface layer concentration of antimony (Sb) after etch is expected to be below 2%.

| Parameter | SU8aniso etch | SU8iso etch |

|---|---|---|

| O2 (sccm) | 99 | 99 |

| SF6 (sccm) | 17 | 14 |

| Pressure (mTorr) | 40 | 20 |

| Coil power (W) | 800 | 800 |

| Platen power (W) | 30 | 0 |

| Temperature (oC) | 30 | 10 |

| Etch rate (nm/min) | ~400 | ~170 |

| anisotropy | ~0.8 | ~0.3 |

| Sb in surface layer (%) | <2 | <2.75 |

SU8iso

The SU8iso etch was developed for thinning of lithography defined structures to gain higher aspect ratio or thinner structures than possible with photo lithography.