Specific Process Knowledge/Etch/Aluminum Oxide/Al2O3 Etch using HF: Difference between revisions

| Line 10: | Line 10: | ||

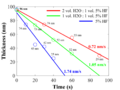

Si samples with about 100 nm of [[Specific_Process_Knowledge/Thin_film_deposition/ALD_Picosun_R200|ALD]] deposited Al<sub>2</sub>O<sub>3</sub> (1000 cycles at 300<sup>o</sup>C) has been etched in different HF concentrations. After the etching, the thickness of the Al<sub>2</sub>O<sub>3</sub> layer has been measured, and the thickness as function of time has been plotted as shown in the graph below. | Si samples with about 100 nm of [[Specific_Process_Knowledge/Thin_film_deposition/ALD_Picosun_R200|ALD]] deposited Al<sub>2</sub>O<sub>3</sub> (1000 cycles at 300<sup>o</sup>C) has been etched in different HF concentrations. After the etching, the thickness of the Al<sub>2</sub>O<sub>3</sub> layer has been measured, and the thickness as function of time has been plotted as shown in the graph below. | ||

<gallery caption="attempt to dissolve Al<sub>2</sub>O<sub>3</sub> with HF." widths=" | <gallery caption="attempt to dissolve Al<sub>2</sub>O<sub>3</sub> with HF." widths="500px" heights="500px"> | ||

image:AL203_Hf_etch.jpg | image:AL203_Hf_etch.jpg | ||

</gallery> | </gallery> | ||

Revision as of 10:14, 26 August 2019

Feedback to this page: click here

THIS PAGE IS UNDER CONSTRUCTION

A wet chemical etch of Al2O3 can be done with HF. The etch rate depends on the HF concentration.

Experiment and results

Si samples with about 100 nm of ALD deposited Al2O3 (1000 cycles at 300oC) has been etched in different HF concentrations. After the etching, the thickness of the Al2O3 layer has been measured, and the thickness as function of time has been plotted as shown in the graph below.

- attempt to dissolve Al<sub

The etch rates:

- 5% HF: 1.74 nm/s

- 1vol. H2O : 1vol. 5% HF 1.05 nm/s

- 2vol. H2O : 1vol. 5% HF 0.723 nm/s

Be aware of that the 5% HF etches quite fast - Actually so fast that it can be tricky to control the etch. Just imagine, you take a sample out of solution and place it in a bigger water container to rinse, and during that movement, the etch continues… So the handling things around the fumehood can be a source of errors.

Evgeniy Shkondin, DTU Nanolab, June 2019