Specific Process Knowledge/Etch/III-V ICP/InP-InGaAsP-InGaAs: Difference between revisions

Appearance

No edit summary |

|||

| Line 61: | Line 61: | ||

===With InP piece on Si carrier=== | ===With InP piece on Si carrier=== | ||

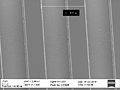

InP piece patterned with SiO2. The pice was etched on topof a Siwafer with out bonding. The InP etch was used. | InP piece patterned with SiO2. The pice was etched on topof a Siwafer with out bonding. The InP etch was used. | ||

<gallery | <gallery caption="Result of InP etching." width="5000px" height="4000px" perrow="3"> | ||

caption="Result of InP etching." | |||

Image:S1_00.jpg | Image:S1_00.jpg | ||

Image:S1_30dg_01.jpg | Image:S1_30dg_01.jpg | ||

Revision as of 12:14, 19 June 2018

Feedback to this page: click here

InP/InGaAsP/InGaAs etch

Unselective etch for large sized features and small aspect ratios by David Larsson, DTU Photonics, 2011

| Recipe | InP Etch 1/InP Precond 1 |

| Cl2 flow | 20 sccm |

| N2 flow | 40 sccm |

| Ar flow | 10 sccm |

| Platen power | 100 W |

| Coil power | 500 W |

| Pressure | 2 mTorr |

| Platen chiller temperature | 180 oC |

| Results (InP Etch 1) | |

| Etch rate | 500-600 nm/min |

| Sidewall angle | 86-87 o |

| Selectivity (InP:SiO2, InP:HSQ) | 50:1 |

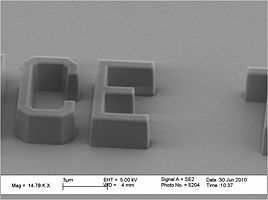

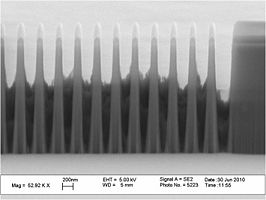

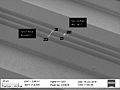

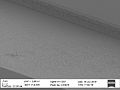

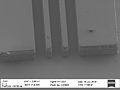

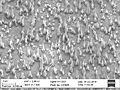

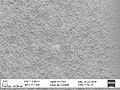

- Result of InP etching. David Larsson, DTU Photonics, 2011

InP etching June 2018

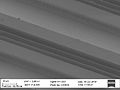

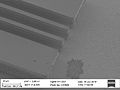

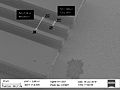

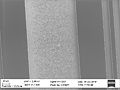

With InP piece on Si carrier

InP piece patterned with SiO2. The pice was etched on topof a Siwafer with out bonding. The InP etch was used.

- Result of InP etching.