Specific Process Knowledge/Etch/ICP Metal Etcher/silicon oxide: Difference between revisions

| Line 87: | Line 87: | ||

*[[/By BGHE|Tests done by Berit]] | *[[/By BGHE|Tests done by Berit]] | ||

*Test by Zhibo Li @Danchip ''dec. 2016'' - based on the work of Peixiong and Berit: [[:File:Zhibo Li SiO2 ICP etch (dose205).docx]] | *Test by Zhibo Li @Danchip ''dec. 2016'' - based on the work of Peixiong and Berit: [[:File:Zhibo Li SiO2 ICP etch (dose205).docx]] | ||

<br/> | |||

[[Image:section under construction.jpg|70px]] | |||

{| border="2" cellspacing="2" cellpadding="3" | |||

|-style="background:Gray; color:White" | |||

!Parameter | |||

!Recipe on ICP metal: A SiO2 etch with C4F8 with resist mask | |||

|- | |||

|Coil Power [W] | |||

|200 | |||

|- | |||

|Platen Power [W] | |||

|25 | |||

|- | |||

|Platen temperature [<sup>o</sup>C] | |||

|0 | |||

|- | |||

|C<sub>4</sub>F<sub>8</sub> flow [sccm] | |||

|20 | |||

|- | |||

|H<sub>2</sub> flow [sccm] | |||

|10 | |||

|- | |||

|Pressure [mTorr] | |||

|3 | |||

|- | |||

|} | |||

{| border="2" cellspacing="2" cellpadding="3" | |||

|-style="background:Black; color:White" | |||

!Results | |||

!Test on wafer with 50% load (Travka 50), by BGHE @danchip | |||

!100% load on 100mm wafers with Barc and KRF (no mask) | |||

|- | |||

|Etch rate of thermal oxide | |||

|'''145 nm/min ''' ''by Martin Lind Ommen (fall 2016)'' | |||

| | |||

|- | |||

|Selectivity to resist [:1] | |||

| (SiO2:resist) | |||

| | |||

|- | |||

|Cr etch rate | |||

|1.6 nm/min (1:90 to SiO2) ''by Martin Lind Ommen (fall 2016)'' | |||

| | |||

|- | |||

|Profile [<sup>o</sup>] | |||

| | |||

| | |||

|- | |||

|Wafer uniformity map (click on the image to view a larger image) | |||

| | |||

| | |||

|- | |||

|SEM profile images | |||

| | |||

| | |||

|- | |||

|Etch rate in barc | |||

| | |||

| | |||

|- | |||

|Etch rate in KRF resist | |||

| | |||

|- | |||

|} | |||

<br/> | <br/> | ||

Revision as of 13:47, 16 January 2017

Feedback to this page: click here

It is possible to etch SiO2 in the ICP metal etcher but it is not designed for it and the results are not fantastic. It is a challenge to get a good selectivity to resist (typically in the range of 1:1 or worse) and it is probably not possible to get a profile angle of 90 degrees. More likely about 75-85 degrees. Different chemistries can be applied either based on CF4 or C4F8. If seems that C4F8 can give the best selectivity to resist (best case I have seem was 1:11 but it depends a lot on the process parameters)). If low coil power is needed CF4 chemistry is used because C4F8 needs a higher power to generate a plasma. /bghe 2016-04-25

Slow etch of SiO2 with resist as masking material - using a 6" carrier wafer with recess

This recipe can be used for slow etching of SiO2 with resist as masking material. Here are some test results presented.

| Parameter | Resist mask |

|---|---|

| Coil Power [W] | 200 |

| Platen Power [W] | 25 |

| Platen temperature [oC] | 0 |

| CF4 flow [sccm] | 20 |

| H2 flow [sccm] | 10 |

| Pressure [mTorr] | 3 |

SiO2 etch using DUV mask

Two chemistry regimes has been explored: One using CF4 and one using C4F8

- CF4: bad selectivity to the resist mask.

- C4F8: Better selectivity to the resist mask can be achieved

- Tests done by Peixiong

- Tests done by Berit

- Test by Zhibo Li @Danchip dec. 2016 - based on the work of Peixiong and Berit: File:Zhibo Li SiO2 ICP etch (dose205).docx

| Parameter | Recipe on ICP metal: A SiO2 etch with C4F8 with resist mask |

|---|---|

| Coil Power [W] | 200 |

| Platen Power [W] | 25 |

| Platen temperature [oC] | 0 |

| C4F8 flow [sccm] | 20 |

| H2 flow [sccm] | 10 |

| Pressure [mTorr] | 3 |

| Results | Test on wafer with 50% load (Travka 50), by BGHE @danchip | 100% load on 100mm wafers with Barc and KRF (no mask) |

|---|---|---|

| Etch rate of thermal oxide | 145 nm/min by Martin Lind Ommen (fall 2016) | |

| Selectivity to resist [:1] | (SiO2:resist) | |

| Cr etch rate | 1.6 nm/min (1:90 to SiO2) by Martin Lind Ommen (fall 2016) | |

| Profile [o] | ||

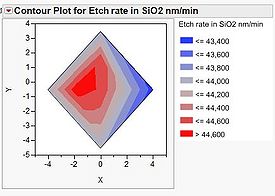

| Wafer uniformity map (click on the image to view a larger image) | ||

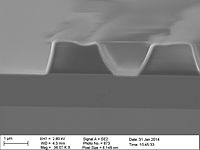

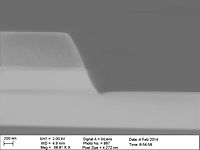

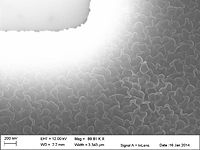

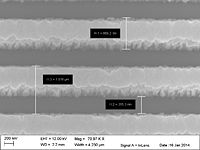

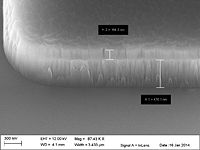

| SEM profile images | ||

| Etch rate in barc | ||

| Etch rate in KRF resist |

SiO2 etch nLOF

| Parameter | Resist mask |

|---|---|

| Coil Power [W] | 800 |

| Platen Power [W] | 100 |

| Platen temperature [oC] | 0 |

| CF4 flow [sccm] | 30 |

| H2 flow [sccm] | 10 |

| Pressure [mTorr] | 4 |

| Results | Test on wafer with 50% load (Travka 50), by BGHE @danchip |

|---|---|

| Etch rate of thermal oxide | >110 nm/min (50% etch load) (09-03-2015) |

| Selectivity to resist [:1] | <0.7:1 (SiO2:resist) |

| Wafer uniformity (100mm) | Not known |

| Profile [o] | Not known |

| Wafer uniformity map (click on the image to view a larger image) | Not known |

| SEM profile images | NONE |

| Etch rate in nLOF resist | 1.6µm was removed after 10min |

| Comment | After 10min etch the resist was gone and the etch depth as 1.145µm in the oxide |

SiO2 etch with e-beam resist

| Process flow |

|---|

px1283lablejan1542014t1 250uc at 40mm x y pxline400p1000jan142014dt2 y= -40 -45 -50 -55mm dose 200 240 280 320uc

|

| Parameter | Resist mask |

|---|---|

| Coil Power [W] | 800 |

| Platen Power [W] | 150 |

| Platen temperature [oC] | -10 |

| C4F8 flow [sccm] | 8 |

| H2 flow [sccm] | 30 |

| Pressure [mTorr] | 2.5 |

| Results | Test on 6" wafer, by Peixiong Shi@danchip |

|---|---|

| Etch rate of thermal oxide | 131 nm/min (15-01-2014) |

| Selectivity to resist [:1] | ~1.8:1 (SiO2:resist) |

| Profile [o] | Not measured |

| Wafer uniformity map (click on the image to view a larger image) | Not known |

| SEM images |

|