Specific Process Knowledge/Lithography/mrEBL6000: Difference between revisions

Appearance

No edit summary |

|||

| Line 36: | Line 36: | ||

== 3 week project on mrEBL6000 by William Tiddi == | == 3 week project on mrEBL6000 by William Tiddi == | ||

mrEBL6000 was studied April 2015 by William Tiddi; the report can be found | mrEBL6000 was studied April 2015 by William Tiddi; the report can be found here: |[[media:Report (2).pdf]] | ||

|[[media:Report (2).pdf]] | |||

<br> | <br> | ||

<br> | <br> | ||

Revision as of 10:57, 6 July 2016

| Resist | Polarity | Manufacturer | Comments | Technical reports | Developer | Rinse | Remover | Process flows (in docx-format) |

| mr EBL 6000.1 | Positive | MicroResist | Standard negative resist | mrEBL6000 processing Guidelines.pdf | mr DEV | IPA | mr REM | Process_Flow_mrEBL6000.docx |

3 week project on mrEBL6000 by William Tiddi

mrEBL6000 was studied April 2015 by William Tiddi; the report can be found here: |media:Report (2).pdf

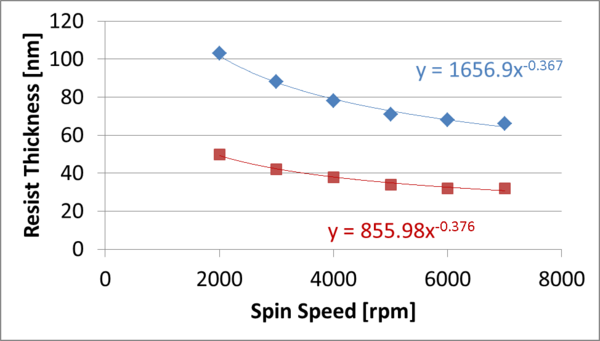

Spin Curve

The thickness is measured on VASE Ellipsometer using a simple Cauchy model for a transparent polymer on Si. The measurements are performed at one incidence angle (70 degrees) only.

9 points on each 4" wafer has been measured; the standard deviation thus representing the homogeinity of the film on the 4" wafers.

| MicroResist mr EBL 6000. Spin coated on Spin Coater: Manual LabSpin A-5, WILTID, 2015. Softbake 3 min @ 110 degC. | ||

|---|---|---|

| Spin Speed [rpm] | Thickness [nm] | St Dev |

| 2000 | 103 | 0.5 |

| 3000 | 88 | 0.4 |

| 4000 | 78 | 0.4 |

| 5000 | 71 | 0.7 |

| 6000 | 68 | 0.5 |

| 7000 | 66 | 0.6 |

| MicroResist mr EBL 6000 diluted 1:1 in anisole. Spin coated on Spin Coater: Manual LabSpin A-5, WILTID, 2015. Softbake 3 min @ 110 degC. | ||

|---|---|---|

| Spin Speed [rpm] | Thickness [nm] | St Dev |

| 2000 | 50 | 0.2 |

| 3000 | 42 | 0.5 |

| 4000 | 38 | 0.5 |

| 5000 | 34 | 0.3 |

| 6000 | 32 | 0.3 |

| 7000 | 32 | 0.3 |