LabAdviser: Difference between revisions

No edit summary |

No edit summary |

||

| Line 7: | Line 7: | ||

'''News in LabAdviser:''' <br/> | '''News in LabAdviser:''' <br/> | ||

The latest monthly LabAdviser update: [[Media: | The latest monthly LabAdviser update: [[Media:Monthly_LabAdviser_update_20160212.docx|LabAdviser update send out 2016-02-12]] <br> | ||

Slides from the customer meeting December 2015: [[media:stormøde 2015 v1.pdf|2015 Customer meeting]] | Slides from the customer meeting December 2015: [[media:stormøde 2015 v1.pdf|2015 Customer meeting]] | ||

<br/> | <br/> | ||

Revision as of 11:36, 12 February 2016

LabAdviser is a process handbook for equipment and processes at the DTU Danchip cleanroom facilities and DTU CEN. The function and capacity of each piece of equipment is described and general process steps, eg photolithography procedures, are clarified. LabAdviser is meant to advise you to a good starting point for your cleanroom process for further optimization to meet your needs. To enter LabAdviser you need to log in with your DTU login. LabAdviser is only editable for Danchip and CEN employees. If you need further information about certain machinery or processes, please contact the Danchip or CEN personnel. Any feedback you might have on LabAdviser is welcome and can be given by mail to the LabAdviser mailbox: labadviser@danchip.dtu.dk

News in LabAdviser:

The latest monthly LabAdviser update: LabAdviser update send out 2016-02-12

Slides from the customer meeting December 2015: 2015 Customer meeting

Contents

- Danchip contact information

- Introduction to LabAdviser and Processing

- Introduction to LabManager

- Process flow approval

- Specific Process Knowledge

- New equipment in the pipeline and old equipment for decommissioning

- Surveys, statistics, monthly LabAdviser updates and other info.

- How to add information to LabAdviser

- CEN overview

Overview of processing steps - a guide to where you can find process information in LabAdviser:

Danchip Contact Info

In order to get the quickest response to training requests, process approvals, questions etc. please use the following mailboxes to DTU Nanolab (formerly known as Danchip).

| Subject | Description | |

| Training and Process Flow | training@nanolab.dtu.dk | All requests regarding equipment training and process flows. Please add your Name to the subject line. Note: Requests are commonly answered within 2 workdays. |

| E-beam training | e-beam@nanolab.dtu.dk | Requests regarding training on JEOL JBX-9500FSZ or Raith Eline e-beam systems. Please study the material on the EBL Labadviser pages beforehand. |

| E-beam Cassette loading | e-beamload@nanolab.dtu.dk | Requests regarding cassette loading on JEOL JBX-9500FSZ. |

| General inquiries | nanolabsupport@nanolab.dtu.dk | Inquiries related to machines, cleanroom access, Mask review, tool changes, and others. Please add your Name to the subject line. Note: Requests are commonly answered within 2 workdays. |

| Metal Wishes | metal@nanolab.dtu.dk | Requests for change of metal in Thin Film Deposition equipment. See current and future materials in statuslog of the respective machines.

|

| Gas-related Requests | DCH-Gas@nanolab.dtu.dk | All topics gas-related (issues, information regarding ordering, delivery, changing etc). Mostly for internal DTU Nanolab use. |

| LabAdviser Mailbox | labadviser@nanolab.dtu.dk | Any questions or feedback to LabAdviser. |

| Commercial Inquiries | sales@nanolab.dtu.dk | For all inquiries regarding in-sourcing, commercial applications, rent of cleanroom space, etc |

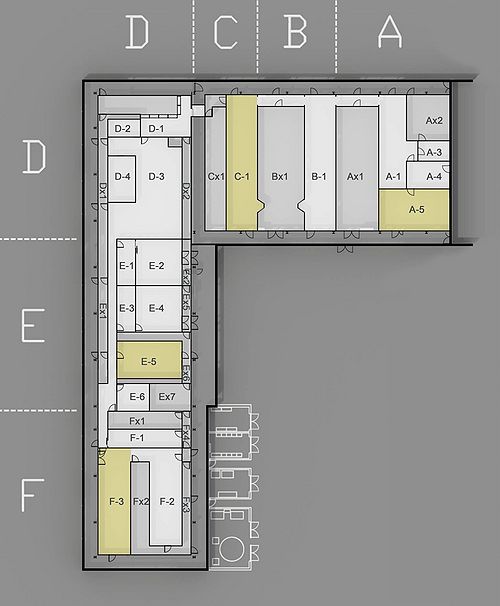

Cleanroom naming and phone numbers

|

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||