Specific Process Knowledge/Thermal Process/Dope with Boron: Difference between revisions

| Line 15: | Line 15: | ||

<gallery caption="Boron deffusion depth vs. pre-deposition time" widths="400px" heights="300px" perrow="3"> | <gallery caption="Boron deffusion depth vs. pre-deposition time" widths="400px" heights="300px" perrow="3"> | ||

image:borDiffusionDepthtable.jpg | image:borDiffusionDepthtable.jpg | ||

image: | image:B_Diff_depth_vs_time_.jpg | ||

<!--image:borDiffusionDepthplot.jpg --> | <!--image:borDiffusionDepthplot.jpg --> | ||

Revision as of 11:49, 7 December 2015

Feedback to this page: click here

Dope with boron

The furnace A1 Boron Drive-in and Pre-dep can be used to pre-deposit silicon wafers with boron. The silicon wafers are positioned in a silicon carbide boat just next to wafers of boron nitride. Pre-deposit of boron is a diffusion process on the silicon wafers.

The concentration of boron in the wafer depends on the process temperature. The depth profile depends of the process time.

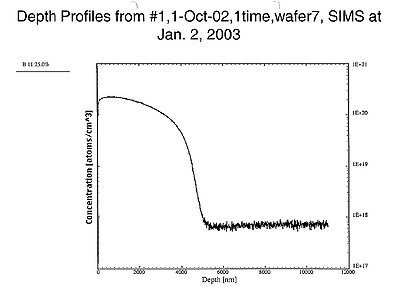

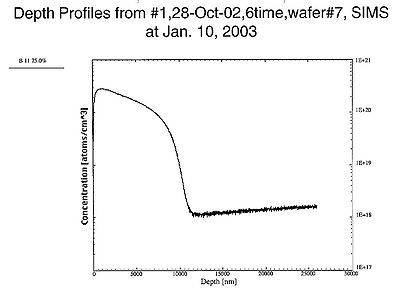

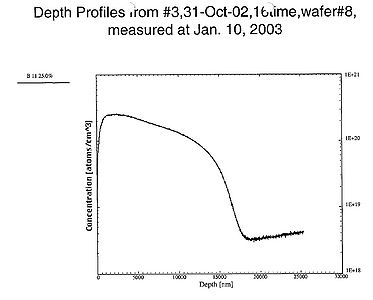

All this figures have been made at the time where there was a furnace only for Boron Pre-dep (furnace A2). The process was done with the temperature at 1125 oC and a flow of 5 slm N2 and 0.2 slm of O2.

- Boron profiles from SIMS

-

Pre-depostion time at 1125 °C 1 hour

-

6 hours

-

16 hours

<gallery caption="Boron deffusion depth vs. pre-deposition time" widths="400px" heights="300px" perrow="3"> image:borDiffusionDepthtable.jpg image:B_Diff_depth_vs_time_.jpg