Specific Process Knowledge/Etch/DRIE-Pegasus/nanobosch/nb-1.0: Difference between revisions

Appearance

Created page with "== Trial runs on HTF stepper wafers 22/6-2012 == {| border="2" cellpadding="2" cellspacing="1" |+ '''Process conditions''' |- ! rowspan="4" align="center"| Substrate informa..." |

|||

| Line 1: | Line 1: | ||

== Trial runs on HTF stepper wafers 22/6-2012 == | == Trial runs on HTF stepper wafers 22/6-2012 == | ||

<!-- revised 1/6-2015 by jmli --> | |||

{| border="2" cellpadding="2" cellspacing="1" | {| border="2" cellpadding="2" cellspacing="1" | ||

|+ '''Process conditions''' | |+ '''Process conditions''' | ||

Revision as of 13:11, 1 June 2015

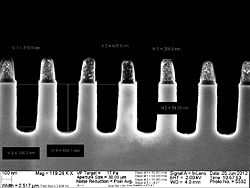

Trial runs on HTF stepper wafers 22/6-2012

| Substrate information | Wafer | S002872 |

|---|---|---|

| Substrate description | 200 nm wide trenches with 400 nm pitch in Barc+stepper resist on quarter 6" wafer CB on oxide carrier | |

| Date | 22/6-2012 | |

| Tool | Pegasus | |

| Process | Recipe | nb-1.0 |

| Tool conditioning | TDESC clean (?) then 30 second barc etch step before etch | |

| Process duration | 3:45 minutes | |

| Purpose | test | |

| Characterisation | SEM Zeiss |

- SEM images

-

-

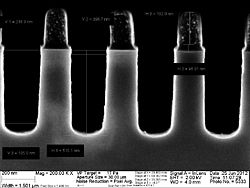

Improved matching 11/9-2012

| Substrate information | Wafer | S003051 |

|---|---|---|

| Substrate description | 200 nm wide trenches with 400 nm pitch in Barc+stepper resist on quarter 6" wafer CB on oxide carrier | |

| Date | 11/9-2012 | |

| Tool | Pegasus | |

| Process | Recipe | nb-1.0 |

| Tool conditioning | TDESC clean (?) then 30 second barc etch step before etch | |

| Process duration | 8:00 minutes or 60 cycles | |

| Purpose | Improved matching | |

| Characterisation | SEM Zeiss |

- SEM images

-

-

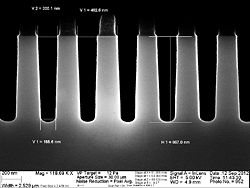

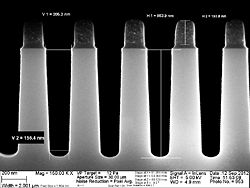

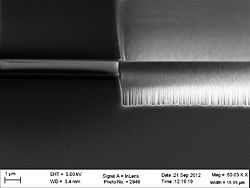

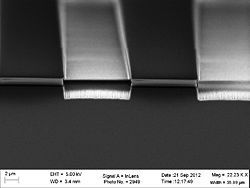

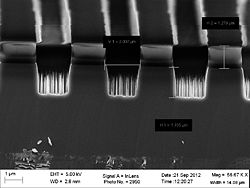

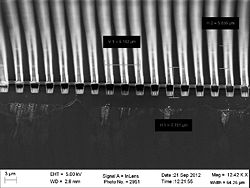

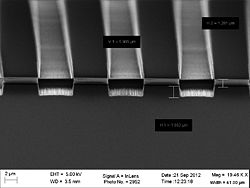

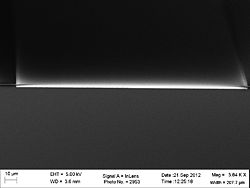

Test run on AZ resist to see if it behaves well, 21/9-2012

| Substrate information | Wafer | C01290.03 |

|---|---|---|

| Mask | 2.2 µm AZ resist | |

| Date | 21/9-2012 | |

| Tool | Pegasus | |

| Process | Run ID | C12090.03 |

| Tool conditioning | 5 minute TDESC clean | |

| Mask description | Travka50 mask | |

| Purpose | See how the nb-1.0 behaves on AZ resist | |

| Characterisation | SEM Leo |

- SEM images

-

-

-

-

-

-