Specific Process Knowledge/Back-end processing/Disco Saw: Difference between revisions

Appearance

No edit summary |

|||

| Line 1: | Line 1: | ||

==Disco Automatic dicing saw, model DAD321== | |||

[[Image:Disco_DAD_321_Dicer.jpg|300x300px|thumb|Dicer positioned on 1. floor bldg 346 room|right]] | [[Image:Disco_DAD_321_Dicer.jpg|300x300px|thumb|Dicer positioned on 1. floor bldg 346 room|right]] | ||

The dicer feature versatile processing capabilities, compact designs, and high precision and reliability. Users perform workpiece loading, alignment, and unloading manually. | The dicer feature versatile processing capabilities, compact designs, and high precision and reliability. Users perform workpiece loading, alignment, and unloading manually. | ||

| Line 65: | Line 64: | ||

==Overview of dicing paramters for different materials== | |||

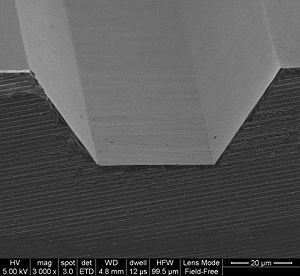

[[Image:Dicetest_001.jpg|300x300px|thumb|test|left]] | [[Image:Dicetest_001.jpg|300x300px|thumb|test|left]] | ||

Revision as of 15:00, 19 February 2008

Disco Automatic dicing saw, model DAD321

The dicer feature versatile processing capabilities, compact designs, and high precision and reliability. Users perform workpiece loading, alignment, and unloading manually.

The dicer at DANCHIP is placed in room ?? on the first floor in bldg. 346. Please notice that this is not a cleanroom and that the dicingproces is very dirty. Think about how to clean your samples if you want to bring them back in the cleanroom.

The dicer can handle up to 6” wafers and 160x160 mm square samples and has a 192 mm cutting range.

A rough overview of the performance Disco DAD321 Dicer

| Purpose | Equipment for dicing out samples. |

|

|---|---|---|

| Performance | Scan range xy |

Line scan x: 50 µm to 200 mm |

| . | Scan range z |

50 Å to 262 µm |

| . | Resolution xy |

down to 0.067 µm |

| . | Resolution z |

1Å, 10Å or 20Å |

| . | Max. scan depth as a function of trench width W |

1.2(W[µm]-5µm) |

| Hardware settings | Tip radius |

|

| Substrates | Substrate size |

|

| . | Substrate material allowed |

|

Overview of dicing paramters for different materials