Specific Process Knowledge/Etch/DRIE-Pegasus/showerheadchange/polySi/Cpoly5: Difference between revisions

Appearance

Created page with " {| border="2" cellpadding="0" cellspacing="0" style="text-align:center;" |+ '''Process runs''' |- ! rowspan="2" width="40"| Date ! colspan="4" width="120"| Substrate Informat..." |

No edit summary |

||

| Line 28: | Line 28: | ||

| | | | ||

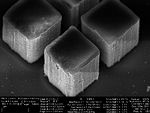

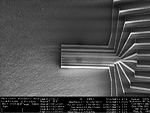

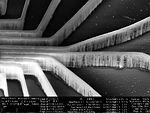

[[file:S004734-01.jpg|150px|frameless ]] | [[file:S004734-01.jpg|150px|frameless ]] | ||

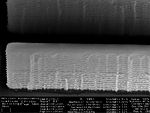

[[file:S004734-03.jpg|150px|frameless ]] | [[file:S004734-03.jpg|150px|frameless ]] | ||

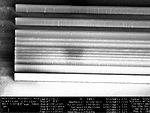

[[file:S004734-04.jpg|150px|frameless ]] | [[file:S004734-04.jpg|150px|frameless ]] | ||

Revision as of 14:03, 11 December 2014

| Date | Substrate Information | Process Information | SEM Images | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Wafer info | Mask | Material/ Exposed area | Tool / Operator | Conditioning | Recipe | Wafer ID | Comments | ||

| 3/12-2014 | 1/4 6" Wafer with 210 nm oxide and 1800 nm polysilicon CB on oxide carrier | standard stepper mask (50 nm barc + 320 nm krf) | Si / 50+ % | Pegasus/jmli | 10 minute TDESC clean + 45 sec barc etch | danchip/jml/showerhead/Cpoly5, 20 cycles or 2:20 minutes | S004734 | New showerhead | |