Specific Process Knowledge/Lithography/CSAR: Difference between revisions

| Line 478: | Line 478: | ||

|} | |} | ||

Revision as of 09:50, 10 September 2014

| Resist | Polarity | Manufacturer | Comments | Technical reports | Spinner | Developer | Rinse | Remover | Process flows (in docx-format) |

| CSAR | Positive | AllResist | Standard positive resist, very similar to ZEP520. | Allresist_CSAR62_English.pdf,, CSAR_62_Abstract_Allresist.pdf | Manual Spinner 1 (Laurell), Spin Coater Labspin | X AR 600-54/6, MIBK:IPA | IPA, H2O | 1165 Remover | Process_Flow_CSAR.docx |

Simple e-beam pattern in this resist has been tested, the results showed on this page. If you have questions to the process or wish to use this e-beam resist, please contact Tine Greibe at tigre@danchip.dtu.dk.

Process Flow

Test of Chemically Semi-Amplified Resist (CSAR); a positive e-beam resist from AllResist (AR-P 6200-2).

| Equipment | Process Parameters | Comments | |

|---|---|---|---|

| Pretreatment | |||

| 4" Si wafers | No Pretreatment | ||

| Spin Coat | |||

| Spin Coater Manual, LabSpin, A-5 | AR-P 6200/2 AllResist E-beam resist

60 sec at various spin speed. Acceleration 4000 s-2, softbake 1 - 5 min at 150 deg Celcius |

Disposal pipette used; clean by N2-gun before use. Use approximately 1.5 ml per 4" wafer, never use a pipette twice. Softbake is not a crucial step, see e-mail correspondence with AllResist here. | |

| Characterization | |||

| Ellipsometer VASE B-1 | 9 points measured on 100 mm wafer | ZEP program used; measured at 70 deg only | |

| E-beam Exposure | |||

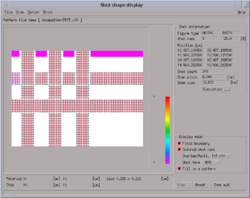

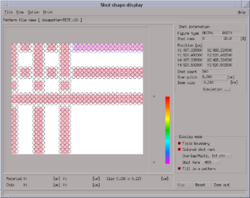

| JEOL 9500 E-beam writer, E-1 | Dosepattern 15nm - 100nm,

dose 120-280 muC/cm2 |

Virtual chip mark height detection (CHIPAL V1) used in corner of every dose array | |

| Development | |||

| Fumehood, D-3 | 60 sec in X AR 600-54/6,

60 sec rinse in IPA, N2 Blow dry |

Gentle agitation while developing. After developing, wafer is immersed in beaker with IPA, subsequently blow dried with N2 gun. | |

| Characterization | |||

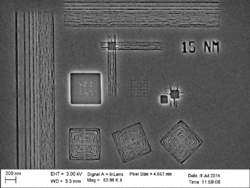

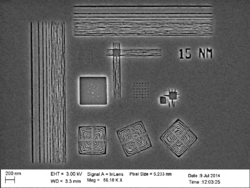

| Zeiss SEM Supra 60VP, D-3 | 2-3 kV, shortest working distance possible, chip mounted with Al tape | The wafers are diced into smaller pieces and sputter coated with Pt at DTU CEN before SEM inspection; please contact Ramona Valentina Mateiu for further information. | |

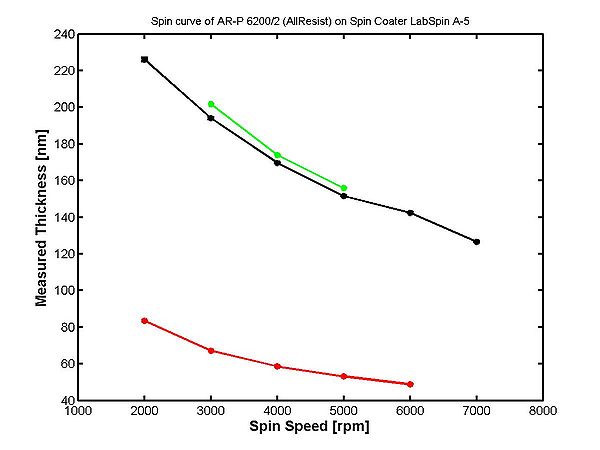

Spin Curves

The thickness is measured on VASE Ellipsometer using a simple Cauchy model for a transparent polymer on Si. The measurements are performed at one incidence angle (70 degrees) only. 9 points on each 4" wafer has been measured; the standard deviation thus representing the homogeinity of the film on the 4" wafers.

Dosepattern has been e-beam exposured and SEM inspected on those wafers marked by silver gray.

| AllResist AR-P 6200/2 spinning on Spin Coater: Manual LabSpin A-5, TIGRE, 09-04-2014. Softbake 5 min @ 150 degC. | ||||||

|---|---|---|---|---|---|---|

| Spin Speed [rpm] | Acceleration [1/s2] | Thickness [nm] | St Dev | |||

| 2000 | 4000 | 225.98 | 0.97 | |||

| 3000 | 4000 | 194.00 | 0.6 | |||

| 4000 | 4000 | 169.57 | 0.32 | |||

| 5000 | 4000 | 151.47 | 0.26 | |||

| 6000 | 4000 | 142.38 | 0.41 | |||

| 7000 | 4000 | 126.59 | 0.36 | |||

| AllResist CSAR on Spin Coater: Manual LabSpin A-5, TIGRE, 16-06-2014. Softbake 2 min @ 150 degC. | ||||||

|---|---|---|---|---|---|---|

| Spin Speed [rpm] | Acceleration [1/s2] | Thickness [nm] | St Dev | |||

| 3000 | 4000 | 201.61 | 1.20 | |||

| 4000 | 4000 | 173.89 | 0.64 | |||

| 5000 | 4000 | 155.91 | 0.65 | |||

| AllResist CSAR 1:1 in anisole, Spin Coater: Manual LabSpin A-5, TIGRE, 16-06-2014. Softbake 2 min @ 150 degC. | ||||||

|---|---|---|---|---|---|---|

| Spin Speed [rpm] | Acceleration [1/s2] | Thickness [nm] | St Dev | |||

| 2000 | 4000 | 83.48 | 0.49 | |||

| 3000 | 4000 | 67.12 | 0.41 | |||

| 4000 | 4000 | 58.64 | 0.44 | |||

| 5000 | 4000 | 53.13 | 0.39 | |||

| 6000 | 4000 | 48.76 | 0.38 | |||

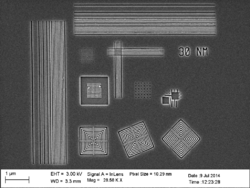

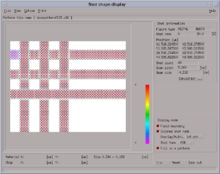

Dosetests

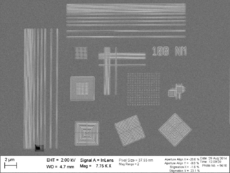

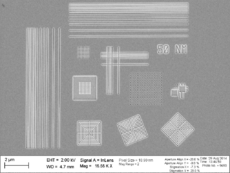

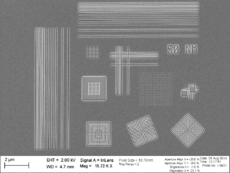

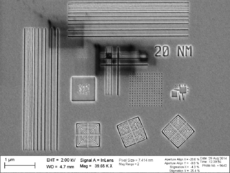

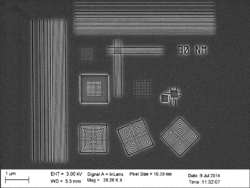

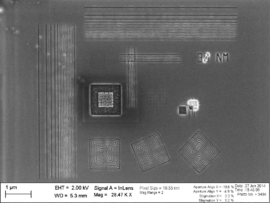

wafer 6.13

| Process | Equipment | Parameters | ||

|---|---|---|---|---|

| 6.13 | 4.09 | 3.05 | ||

| Resist | Fumehood D-3 | Resist: AR-P 6200/2 diluted 1:1 in anisole (Bottled opened 16-06-2014 TIGRE) | Resist: AR-P 6200/2 diluted 1:1 in anisole (Bottled opened 16-06-2014 TIGRE) | Resist: AR-P 6200/2 |

| Spin Coat | Spin Coater LabSpin A-5 | Spin: 1 min @ 6000 rpm, softbake: 1 min @ 150 degC, thickness: ~50nm (27-08-2014 TIGRE) |

Spin: 1 min @ 5000 rpm, softbake: 2 min @ 150 degC, thickness: ~53nm (16-06-2014 TIGRE) |

Spin: 1 min @ 6000 rpm, softbake: 5 min @ 150 degC, thickness: ~143nm (09-04-2014 TIGRE) |

| E-beam exposure | JEOL 9500 E-2 | Condition file: 0.2nA_ap5, doses: 180-420 muC/cm2, Shot pitch: 7-27 nm, PEC: no (27-08-2014 TIGRE) |

Condition file: 0.2nA_ap5, doses: 207-242 muC/cm2, Shot pitch: 5 nm, PEC: no (02-07-2014 TIGRE) |

Condition file: 2nA_ap5, doses: 207-242 muC/cm2, Shot pitch: 5 nm, PEC: no (10-04-2014 TIGRE) |

| Develop | Fumehood D-3 | Developer: SX-AR 600-54/6, time: 30 sec, Rinse: 30 sec in IPA (28-08-2014 TIGRE) |

Developer: SX-AR 600-54/6, time: 60 sec, Rinse: 30 sec in IPA (08-07-2014 TIGRE) |

Developer: SX-AR 600-54/6, time: 60 sec, Rinse: 60 sec in IPA (April/May-2014 TIGRE) |

| Sputter Coat | Cressington 208HR, DTU CEN | 3-5 nm Pt, sputtering (29-08-2014 TIGRE) | 3-5 nm Pt, sputtering (09-07-2014 TIGRE) | 3-5 nm Pt, sputtering (22-05-2014 TIGRE) |

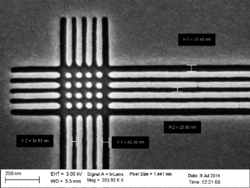

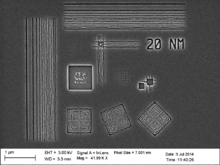

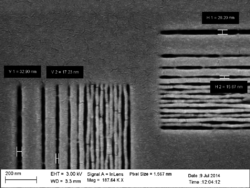

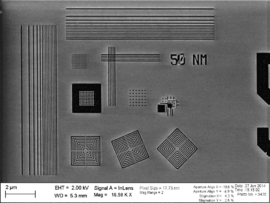

| Characterization | Zeiss SEM Supra 60VP, D-3 | Acc voltage: 3 kV, WD: < 4mm, conducting tape close to pattern (29-08-2014 TIGRE) |

Acc voltage: 3 kV, WD: < 4mm, conducting tape close to pattern (09-07-2014 TIGRE) |

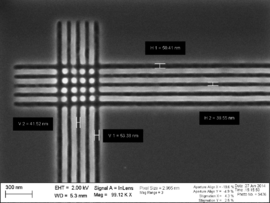

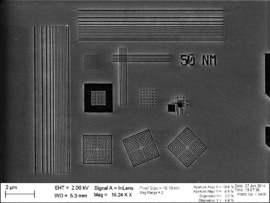

Acc voltage: 2 kV, WD: < 4mm, conducting tape close to pattern (06-06-2014 TIGRE) |

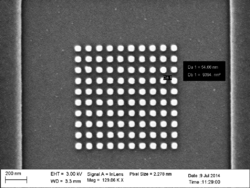

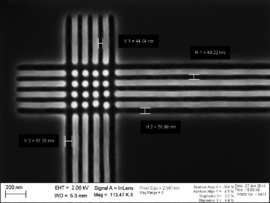

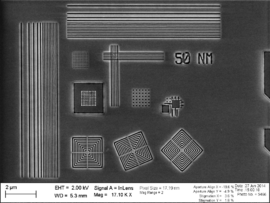

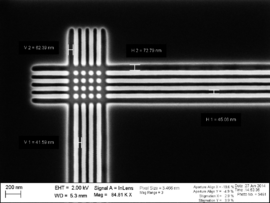

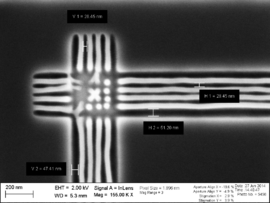

| SEM inspection of wafer 6.13, 100 nm exposed pattern, shot pitch 7 nm | |||||||

|---|---|---|---|---|---|---|---|

| 300 [muC/cm2] |

|

|

|

|

|

|

ACHK NOT READY |

| SEM inspection of wafer 6.13, 50 nm exposed pattern, shot pitch 7 nm | ||||||

|---|---|---|---|---|---|---|

| 270 [muC/cm2] |

|

|

|

|

|

ACHK NOT READY |

| 300 [muC/cm2] |

|

|

|

|

|

ACHK NOT READY |

| SEM inspection of wafer 6.13, 30 nm exposed pattern, shot pitch 7 nm | |||||

|---|---|---|---|---|---|

| 240 [muC/cm2] |

|

|

ACHK NOT READY | ||

| 270 [muC/cm2] |

|

|

|

|

ACHK NOT READY |

| 300 [muC/cm2] |

|

|

|

|

ACHK NOT READY |

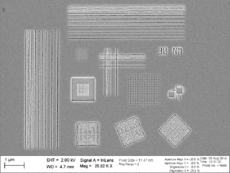

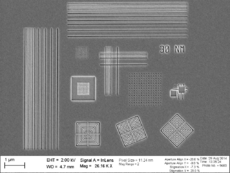

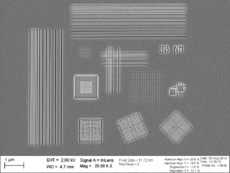

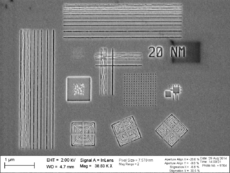

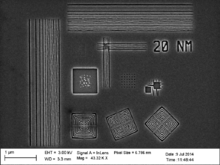

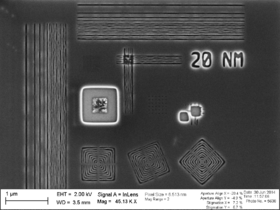

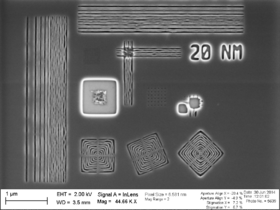

| SEM inspection of wafer 6.13, 20 nm exposed pattern, shot pitch 7 nm | |||

|---|---|---|---|

| 270 [muC/cm2] |

|

|

ACHK NOT READY |

| 300 [muC/cm2] |

|

|

ACHK NOT READY |

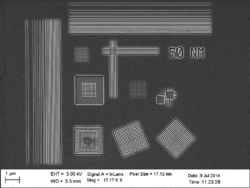

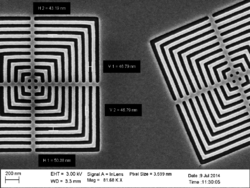

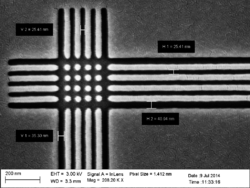

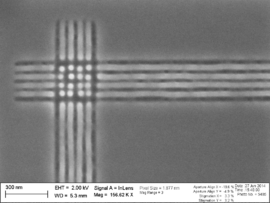

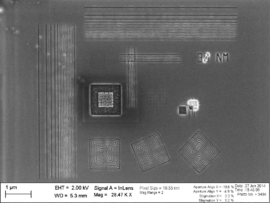

| SEM inspection of wafer 4.09, 50 nm exposed pattern, shot pitch 5 nm | |||||

|---|---|---|---|---|---|

| 230 [muC/cm2] |

|

|

|

|

|

| SEM inspection of wafer 4.09, 30 nm exposed pattern, shot pitch 5 nm | |||

|---|---|---|---|

| 219 [muC/cm2] |

|

|

|

| 230 [muC/cm2] |

|

|

|

| 242 [muC/cm2] |

|

|

|

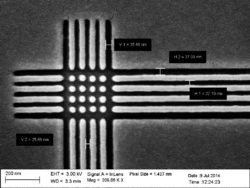

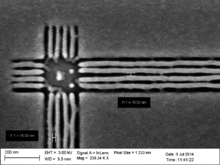

| SEM inspection of wafer 4.09, 20 nm exposed pattern, shot pitch 5 nm | |||

|---|---|---|---|

| 230 [muC/cm2] |

|

|

|

| 242 [muC/cm2] |

|

|

|

| 253 [muC/cm2] |

|

|

|

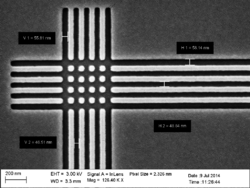

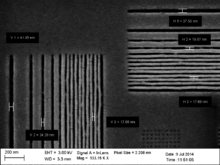

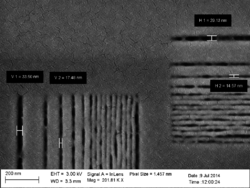

| SEM inspection of wafer 4.09, 15 nm exposed pattern, shot pitch 5 nm | |||

|---|---|---|---|

| 253 [muC/cm2] |

|

|

|

| 276 [muC/cm2] |

|

|

|

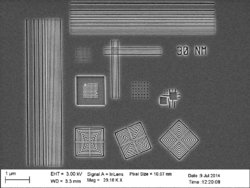

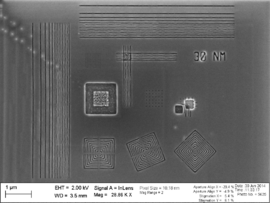

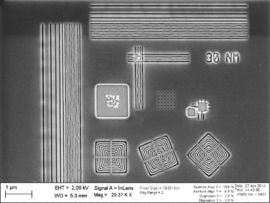

Wafer 3.05

| Process | Equipment | Parameters | Date and initials |

|---|---|---|---|

| Resist | Fumehood D-3 | AR-P 6200/2 AllResist E-beam resist | 2013 (bottle opened) |

| Spin Coat | Spin Coater LabSpin A-5 | 1 min @ 6000 rpm, 4000 1/s2, softbake 5 min @ 150 degC, thickness ~143nm | 09-04-2014 TIGRE |

| E-beam exposure | JEOL 9500 E-2 | 2 nA, aperture 5, dose 207-242 muC/cm2, SHOT A,10, No proximity error correction | 10-04-2014 TIGRE |

| Develop | Fumehood D-3 | SX-AR 600-54/6 60 sec, 60 sec IPA rinse | April/May-2014 TIGRE |

| Sputter Coat | Cressington 208HR, DTU CEN | 2-3 nm Pt, sputtering | 22-05-2014 TIGRE |

| Characterization | Zeiss SEM Supra 60VP, D-3 | 2 kV, WD below 4mm, conducting tape close to pattern | 06-06-2014, TIGRE |

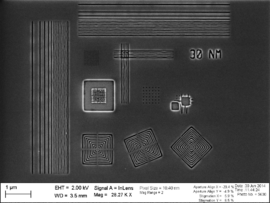

| SEM inspection of wafer 3.05, 50 nm exposed pattern, shot pitch 5 nm | |||

|---|---|---|---|

| 207 [muC/cm2] |

|

|

NO ACHK READY |

| 219 [muC/cm2] |

|

|

|

| 230 [muC/cm2] |

|

|

|

| 242 [muC/cm2] |

|

|

|

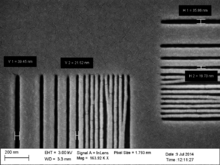

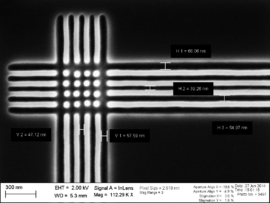

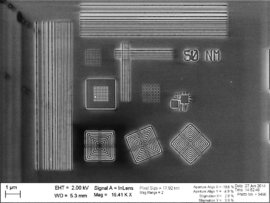

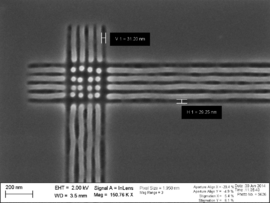

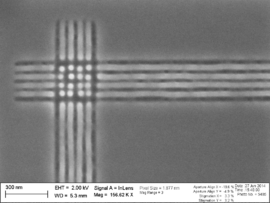

| SEM inspection of wafer 3.05, 30 nm exposed pattern, shot pitch 5 nm | |||

|---|---|---|---|

| 207 [muC/cm2] |

|

|

NO ACHK READY |

| 219 [muC/cm2] |

|

|

|

| 230 [muC/cm2] |

|

|

|

| 242 [muC/cm2] |

|

|

|

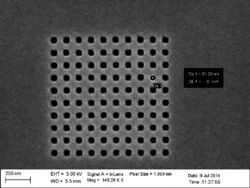

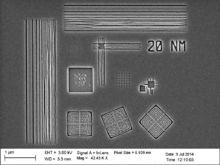

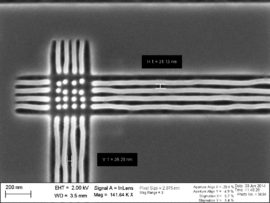

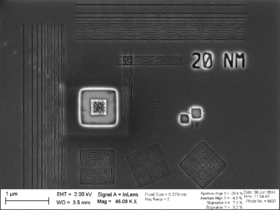

| SEM inspection of wafer 3.05, 20 nm exposed pattern, shot pitch 5 nm | |||

|---|---|---|---|

| 207 [muC/cm2] |

|

|

NO ACHK READY |

| 230 [muC/cm2] |

|

||

| 242 [muC/cm2] |

|

||

| 253 [muC/cm2] |

|

||