Specific Process Knowledge/Lithography/ZEP520A: Difference between revisions

Appearance

Created page with "These tests are currently in progress and this page thus under construction. If you have questions to the process or wish to use this e-beam resist, please contact Tine Greibe..." |

|||

| Line 3: | Line 3: | ||

== Process Flow == | == Process Flow == | ||

Test of | Test of ZEP resist; a positive e-beam resist from ZEON. | ||

{|border="1" cellspacing="0" cellpadding="3" style="text-align:left;" | {|border="1" cellspacing="0" cellpadding="3" style="text-align:left;" | ||

| Line 27: | Line 27: | ||

|No Pretreatment | |No Pretreatment | ||

| | | | ||

|TIGRE, | |TIGRE, 23-04-2014 | ||

|- | |- | ||

| Line 39: | Line 39: | ||

|-style="background:LightGrey; color:black" | |-style="background:LightGrey; color:black" | ||

|Spin Coater Manual, LabSpin, A-5 | |Spin Coater Manual, LabSpin, A-5 | ||

| | |ZEP520A 1:1 E-beam resist | ||

60 sec at various spin speed. | 60 sec at various spin speed. | ||

Acceleration 4000 s-2, | Acceleration 4000 s-2, | ||

softbake | softbake 2 min at 180 deg Celcius | ||

|Resist poured directly from bottle | |Resist poured directly from bottle | ||

|TIGRE, | |TIGRE, 23-04-2014 | ||

|- | |- | ||

| Line 57: | Line 57: | ||

|9 points measured on 100 mm wafer | |9 points measured on 100 mm wafer | ||

|ZEP program used; measured at 70 deg only | |ZEP program used; measured at 70 deg only | ||

|TIGRE, | |TIGRE, 23-04-2014 | ||

|- | |- | ||

| Line 72: | Line 72: | ||

dose 120-280 muC/cm2 | dose 120-280 muC/cm2 | ||

|Virtual chip mark height detection | |Virtual chip mark height detection | ||

| TIGRE, | | TIGRE, 23-04-2014 | ||

|- | |- | ||

| Line 83: | Line 83: | ||

|-style="background:LightGrey; color:black" | |-style="background:LightGrey; color:black" | ||

|Fumehood, D-3 | |Fumehood, D-3 | ||

|60 sec in | |60 sec in , | ||

60 sec rinse in IPA, | 60 sec rinse in IPA, | ||

N2 Blow dry | N2 Blow dry | ||

|Agitation (by hand) while developing | |Agitation (by hand) while developing | ||

| TIGRE, | | TIGRE, XX-04-2014 | ||

|- | |- | ||

| Line 104: | Line 104: | ||

|} | |} | ||

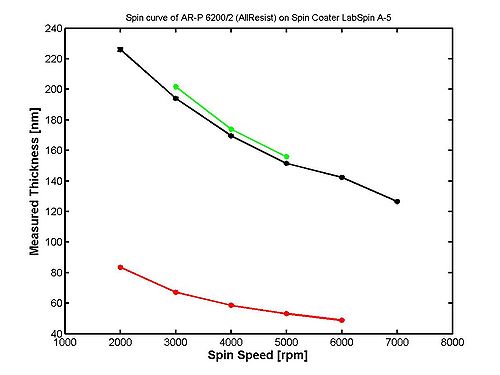

== Spin Curve == | == Spin Curve == | ||

Revision as of 11:42, 23 April 2014

These tests are currently in progress and this page thus under construction. If you have questions to the process or wish to use this e-beam resist, please contact Tine Greibe at tigre@danchip.dtu.dk.

Process Flow

Test of ZEP resist; a positive e-beam resist from ZEON.

| Equipment | Process Parameters | Comments | Initials and date |

|---|---|---|---|

| Pretreatment | |||

| 4" Si wafers | No Pretreatment | TIGRE, 23-04-2014 | |

| Spin Coat | |||

| Spin Coater Manual, LabSpin, A-5 | ZEP520A 1:1 E-beam resist

60 sec at various spin speed. Acceleration 4000 s-2, softbake 2 min at 180 deg Celcius |

Resist poured directly from bottle | TIGRE, 23-04-2014 |

| Characterization | |||

| Ellipsometer VASE B-1 | 9 points measured on 100 mm wafer | ZEP program used; measured at 70 deg only | TIGRE, 23-04-2014 |

| E-beam Exposure | |||

| JEOL 9500 E-beam writer, E-1 | Dosepattern 14nm - 100nm,

dose 120-280 muC/cm2 |

Virtual chip mark height detection | TIGRE, 23-04-2014 |

| Development | |||

| Fumehood, D-3 | 60 sec in ,

60 sec rinse in IPA, N2 Blow dry |

Agitation (by hand) while developing | TIGRE, XX-04-2014 |

| Characterization | |||

| Zeiss SEM Supra 60VP, D-3 | TIGRE, ??-04-2014 | ||

Spin Curve

The thickness is measured on VASE Ellipsometer using a simple Cauchy model for a transparent polymer on Si. The measurements are performed at one incidence angle (70 degrees) only. 9 points on each 4" wafer has been measured; the standard deviation thus representing the homogeinity of the film on the 4" wafers.

| AllResist AR-P 6200/2 spinning on Spin Coater: Manual LabSpin A-5, TIGRE, 09-04-2014 | ||||||

|---|---|---|---|---|---|---|

| Spin Speed [rpm] | Acceleration [1/s2] | Thickness [nm] | St Dev | |||

| 2000 | 4000 | 225.98 | 0.97 | |||

| 3000 | 4000 | 194.00 | 0.6 | |||

| 4000 | 4000 | 169.57 | 0.32 | |||

| 5000 | 4000 | 151.47 | 0.26 | |||

| 6000 | 4000 | 142.38 | 0.41 | |||

| 7000 | 4000 | 126.59 | 0.36 | |||