Specific Process Knowledge/Lithography/Pretreatment: Difference between revisions

| Line 68: | Line 68: | ||

==Spin Track 1 + 2== | ==Spin Track 1 + 2== | ||

[[Specific Process Knowledge/Lithography/Coaters#Spin Track 1 + 2| | [[Specific Process Knowledge/Lithography/Coaters#Spin Track 1 + 2|Specific process knowledge on Spin Track 1 + 2]] | ||

[[Specific Process Knowledge/Lithography/Coaters/Spin Track 1 + 2 processing#HMDS priming only|HMDS priming on Spin Track 1 and 2]] | [[Specific Process Knowledge/Lithography/Coaters/Spin Track 1 + 2 processing#HMDS priming only|HMDS priming on Spin Track 1 and 2]] | ||

Revision as of 09:35, 3 February 2014

Feedback to this page: click here

Pretreatment

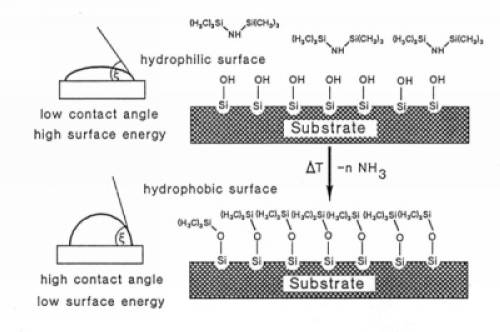

All surfaces can be divided to hydrophilic or hydrophobic surfaces, where the oxidized surfaces such SiO2 or surface with native oxide formation on Si or Al substrates consider to be hydrophilic and have very bad wetting with hydrophobic resist.

Therefore it is very important to do the pretreatment step before the spinning. Here we will give an overview of treatment which Danchip recommend to render the surface hydrophobic.

HMDS

The chemical treatment with hexamethyldisilazane (HMDS) before the spin coating can be used to promote the adhesion for photoresist. HMDS treatment leaves a coating of TMS (trimethylsilyl) on the Si or SiO2 surface.

The molecular formula for hexamethyldisilazane, or bis(trimethylsilyl)amine, is C6H19NSi2. Here is a schematic overview of HMDS treatment of silicon-oxide surface.

HMDS oven

At Danchip we use Star2000 model from IMTEC to do prime vapor deposition of hexamethyldisilizane(HMDS)under the special conditions: low pressure and hight chamber tempurature. The result of the dehydration bake and HMDS prime is that the wafers become hydrophobic after the treatment.

The user manual, user APV, and contact information can be found in LabManager:

Overview of the main recipe:

1. Dehydration and purging nitrogen for ca. 12 min.

2. Priming of HMDS vapor ca. 7 min.

3. Purging prime exhaust for ca. 5 min.

4. Backfill, return to atmosphere pressure ca. 3. min.

Overview of HMDS process:

| Pretreatment in HMDS oven | |

|---|---|

| General description | Promotion of photoresist adhesion |

| Chemical solution | hexamethyldisilizane |

| Process temperature | 150 oC |

| Process time | 27 min. |

| Batch size | 1-15 wafers at a time, more than 1 batch a time |

| Size of substrate | 2"-6" wafers |

Spin Track 1 + 2

Specific process knowledge on Spin Track 1 + 2

HMDS priming on Spin Track 1 and 2

HMDS priming on Spin Track 1 and 2

BHF

Another commonly used method to render the surface of silicon wafers hydrophobic is the dilute HF dip.

BHF is mostly used to do pretreatment step for new Si wafers. The native dioxide layer will be removed during 30 sec etching and in this way we will promote the resist adhesion on the Si substrates. We recommend to spin resist asap after the procedure.

250C Oven for Pretreatment

The oven is typically used for pretreatment (dehydration) of Si and glass substrates to promote the resist adhesion. We recommend to place the wafers in metal carrier in the oven at least for 4 hours, better during the night, and spin the resist on them asap.