Specific Process Knowledge/Etch/Etching of TOPAS: Difference between revisions

Appearance

| Line 44: | Line 44: | ||

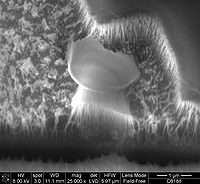

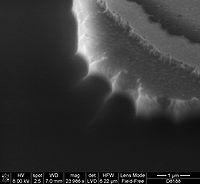

==Under etching and local masking== | ==Under etching and local masking== | ||

{| border="1" cellspacing="1" cellpadding="2" align="left" | {| border="1" cellspacing="1" cellpadding="2" align="left" | ||

! Silicon hard mask | ! Silicon hard mask|! Aluminum hard mask | ||

! Aluminum hard mask | |||

|- | |- | ||

|[[Image:TOPAS-Si-hard-mask_U50.jpg|200x200px]] | |[[Image:TOPAS-Si-hard-mask_U50.jpg|200x200px]] | ||

Revision as of 10:59, 4 November 2013

Etching of TOPAS

TOPAS is etched by an oxygen plasma in the ASE. Masking of TOPAS was achieved by photo resist or a hard mask of aluminum or silicon. Photo resist is the preferred masking material, since hard masks tends to introduce local masking due to redeposition. TOPAS can be etched at rates up to 500 nm/min, with excellent uniformity over the wafer.

| Parameter | Slow TOPAS etch | Fast TOPAS etch |

|---|---|---|

| O2 (sccm) | 50 | 99 |

| CO2 (sccm) | 50 | 0 |

| Pressure (mTorr) | 40 | 40 |

| Coil power (W) | 800 | 720 |

| Platen power (W) | 60 | 60 |

| Temperature (oC) | 20 | 20 |

| Etch rate (nm/min) | ~350 | ~500 |

| Center-Edge uniformity | 0.98 | 0.95 |