Specific Process Knowledge/Etch/Etching of SU-8: Difference between revisions

No edit summary |

|||

| Line 57: | Line 57: | ||

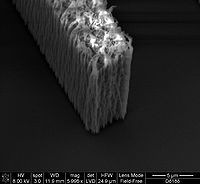

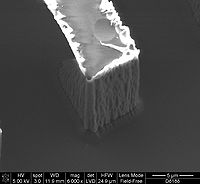

==Roughness and antimony effects in SU-8 etching== | ==Roughness and antimony effects in SU-8 etching== | ||

{| border="1" cellspacing="1" cellpadding="2" align="left" | |||

! Oxygen etch | |||

! SU8aniso | |||

! SU8iso | |||

|- | |||

|[[Image:SU8-oxygen-etch_Q12.jpg|200x200px]] | |||

|[[Image:SU8-SU8aniso_R15.jpg|200x200px]] | |||

| | |||

|} | |||

Revision as of 09:04, 4 November 2013

Etching of SU-8

SU-8 can be etched by a oxygen plasma with a small amount of SF6 to remove the antimony present from the photo initiator. Etching of SU-8 has been developed on the ASE and was tested as a mask less reduction of pattern defined by photo lithography. Two processes are available, a high and a low anisotropic etch for use as etching or thinning of structures.

- High anisotropic etch: etch rate ~400nm/min, anisotropy ~0.8

- Low anisotropic etch: etch rate ~170nm/min, anisotropy ~0.3

Recipes in ASE

SU8aniso

The anisotropic SU8aniso etch was design to etch structures in SU-8 with a low roughness of the etched surface, however it has not been tested with any mask material. For a polymeric mask a low selectivity is expected. The etch rate was measured to around 400 nm/min, but will depend on wafer coverage. The surface layer concentration of antimony (Sb) after etch is expected to be below 2%.

| Parameter | SU8aniso etch | SU8iso etch |

|---|---|---|

| O2 (sccm) | 99 | 99 |

| SF6 (sccm) | 17 | 14 |

| Pressure (mTorr) | 40 | 20 |

| Coil power (W) | 800 | 800 |

| Platen power (W) | 30 | 0 |

| Temperature (oC) | 30 | 10 |

| Etch rate (nm/min) | ~400 | ~170 |

| anisotropy | ~0.8 | ~0.3 |

| Sb in surface layer (%) | <2 | <2.75 |

SU8iso

The SU8iso etch was developed for thinning of lithography defined structures to gain higher aspect ratio or thinner structures than possible with photo lithography.

Roughness and antimony effects in SU-8 etching

| Oxygen etch | SU8aniso | SU8iso |

|---|---|---|

|

|