Specific Process Knowledge/Etch/Etching of Gold: Difference between revisions

Appearance

| Line 83: | Line 83: | ||

![[Specific Process Knowledge/Etch/Wet Aluminium Etch|Al wet etch 1]] | ![[Specific Process Knowledge/Etch/Wet Aluminium Etch|Al wet etch 1]] | ||

![[Specific Process Knowledge/Etch/Wet Aluminium Etch|Al wet etch 2]] | ![[Specific Process Knowledge/Etch/Wet Aluminium Etch|Al wet etch 2]] | ||

![[Specific_Process_Knowledge/Etch/IBE⁄IBSD Ionfab 300|IBE (Ionfab300+)]] | ![[Specific_Process_Knowledge/Etch/IBE⁄IBSD Ionfab 300|IBE (Ionfab300+)]] | ||

|- | |- | ||

| Line 92: | Line 91: | ||

|Wet etch of pure Al | |Wet etch of pure Al | ||

|Wet etch of Al + 1.5% Si | |Wet etch of Al + 1.5% Si | ||

|Sputtering of Al - pure physical etch | |Sputtering of Al - pure physical etch | ||

|- | |- | ||

| Line 104: | Line 102: | ||

*~60nm/min (Al+1.5% Si) | *~60nm/min (Al+1.5% Si) | ||

| | | | ||

| | | | ||

*~30nm/min (not tested yet) | *~30nm/min (not tested yet) | ||

| Line 116: | Line 113: | ||

| | | | ||

*Isotropic | *Isotropic | ||

| | | | ||

*Anisotropic (angles sidewalls, typical around 70 dg) | *Anisotropic (angles sidewalls, typical around 70 dg) | ||

| Line 130: | Line 125: | ||

| | | | ||

*<nowiki>#</nowiki>1-25 100 mm wafers | *<nowiki>#</nowiki>1-25 100 mm wafers | ||

| | | | ||

Smaller pieces glued to carrier wafer | Smaller pieces glued to carrier wafer | ||

| Line 161: | Line 152: | ||

*Photoresist | *Photoresist | ||

*E-beam resist | *E-beam resist | ||

| | | | ||

*Silicon | *Silicon | ||

Revision as of 09:25, 8 April 2013

Ething of Gold can be done either wet or dry. For wet etching please see below on this page. Dry etching can be done with IBE by sputtering with Ar ions.

Etching of Gold

Etching of Gold is done wet at Danchip making your own set up in a beaker in the fumehood. We have two different solutions:

- Iodine etch: KI:I2:H2O - 100g:25g:500ml - standard at Danchip. Can be used with AZ resist as mask.

- Aqua Regia (Kongevand): HNO3:HCl - 1:3 - A very strong acid witch will etch most metals and are therefore used when you wish to remove all the gold from your wafer. you have to be very carefull when you work with Aqua Regia (Kongevand) It can generate nitrous gases witch are very toxic!!

Comparing the two solutions

| Iodine based gold etch | Aqua Regia (Kongevand) | |

|---|---|---|

| General description |

Etch of pure Gold with or without photoresist mask. |

Etch of pure Gold (as stripper). |

| Chemical solution | KI:I2:H2O (100g:25g:500ml) | HCl:HNO3 (3:1) |

| Process temperature | 20 oC | 20 oC |

| Possible masking materials |

Photoresist (1.5 µm AZ5214E) |

Unmasked - used as a stripper |

| Etch rate |

~100 nm/min |

~(??) nm/min - fast etch |

| Batch size |

1-5 4" wafers at a time |

1-5 4" wafer at a time |

| Size of substrate |

2-6" wafers |

2-6" wafers |

Feedback to this page: click here

THIS PAGE IS UNDER CONSTRUCTION

Etching of Gold

Etching of Gold can be done either by wet etch, dry etch or by sputtering with ions.

Comparison of Gold Etch Methods

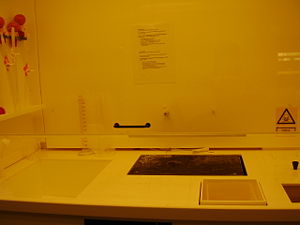

| Al wet etch 1 | Al wet etch 2 | IBE (Ionfab300+) | ||

|---|---|---|---|---|

| Generel description | Wet etch of pure Al | Wet etch of Al + 1.5% Si | Sputtering of Al - pure physical etch | |

| Etch rate range |

|

|

| |

| Etch profile |

|

|

| |

| Substrate size |

|

|

Smaller pieces glued to carrier wafer

| |

| Allowed materials |

|

|

|