Specific Process Knowledge/Characterization/SEM: Scanning Electron Microscopy: Difference between revisions

No edit summary |

|||

| Line 91: | Line 91: | ||

|style="background:LightGrey; color:black"|Stage | |style="background:LightGrey; color:black"|Stage | ||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| | ||

* | * X, Y: 125*100 mm | ||

* T: 0 to 90<sup>o</sup> | |||

* R: 360<sup>o</sup> | |||

* Z: 48 mm | |||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| | ||

* | * X, Y: 130*130 mm | ||

* T: -4 to 70<sup>o</sup> | |||

* R: 360<sup>o</sup> | |||

* Z: 50 mm | |||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| | ||

* | * X, Y: 150*150 mm | ||

* T: -10 to 60<sup>o</sup> | |||

* R: 360<sup>o</sup> | |||

* Z: 10 mm | |||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| | ||

* | * X, Y: 73*40 mm | ||

* T: -10 to 90<sup>o</sup> | |||

* R: 360<sup>o</sup> | |||

* Z: 38 mm | |||

|- | |- | ||

|style="background:LightGrey; color:black"|Electron source | |style="background:LightGrey; color:black"|Electron source | ||

| Line 124: | Line 138: | ||

|style="background:LightGrey; color:black"|Sample sizes | |style="background:LightGrey; color:black"|Sample sizes | ||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| | ||

* | * X, Y, Z, R and T | ||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| | ||

* | * Up to 6" wafer with full view | ||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| | ||

* | * Up to 6" wafer with full view | ||

* A 12" wafer holder has been made but it requires special training | |||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| | ||

* | * Up to 4" wafer | ||

|- | |- | ||

| style="background:LightGrey; color:black"|Allowed materials | | style="background:LightGrey; color:black"|Allowed materials | ||

Revision as of 10:30, 3 December 2012

Scanning electron microscopy at Danchip

The four SEM's at Danchip cover a wide range of needs both in the cleanroom and outside: From the fast in-process verification of different process parameters such as etch rates, step coverages or lift-off quality to the ultra high resolution images on any type of sample intended for publication.

The 'workhorse' SEM that will cover most users needs is the Leo SEM. It is a very reliable and rugged instrument that provides high quality images of most samples. Excellent images on a large variety of materials such as semiconductors, semiconductor oxides or nitrides, metals, thin films and some polymers may be acquired on the Leo SEM. As such, we prefer that new users that have no prior SEM experience get trained on the Leo SEM before they start using the FEI or Zeiss.

The Zeiss SEM is the newest SEM in the cleanroom. It's a state-of-the-art SEM that will produce excellent images on almost any sample. Operated by the same user interface as the Leo, it is quite straight forward to change between the two instruments.

The FEI SEM was acquired to cope with the growing need for polymer related imaging. It is a versatile microscope with two vacuum modes (High Vacuum and Low Vacuum) and 6 different detectors, offering excellent resolution on any type of sample or material. This great performance, however, requires a skilled operator that knows how to achieve it. Also, we have learned that the high degree of sophistication and the great number of detectors make it much less robust compared to the other SEM's. It is therefore the intention that only users with special needs (for instance thick polymers, glass substrates or EDX/micromanipulator experiments) that will be trained. Furthermore, the instrument is equipped with a Oxford Inca EDX system and a Kleindiek micromanipulator with a Capres 4 point probe.

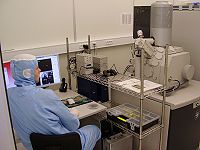

Outside the cleanroom in the basement of building 347, the Jeol SEM provides a possibilty of imaging samples that do not go into the cleanroom.

The user manuals, quality control procedures and results, user APVs, technical information and contact information can be found in LabManager:

- The SEM Leo page in LabManager,

- The SEM FEI page in LabManager,

- The SEM Zeiss page in LabManager,

- The SEM Jeol page in LabManager,

Process information

| Equipment | SEM Leo | SEM Zeiss | SEM FEI | SEM Jeol | |

|---|---|---|---|---|---|

| Purpose | Imaging |

|

|

|

|

| Performance | Resolution |

|

|

|

|

| Optimum usage |

|

|

|

| |

| Process parameter range | Detectors |

|

|

|

|

| Stage |

|

|

|

| |

| Electron source |

|

|

|

| |

| Operating pressures |

|

|

|

| |

| Substrates | Sample sizes |

|

|

|

|

| Allowed materials |

|

|

|

| |

| SEM - Zeiss | SEM - FEI | SEM - Leo | SEM - Jeol | |

|---|---|---|---|---|

| Model | Zeiss Supra 55 VP | FEI Nova 600 NanoSEM | Leo 1550 SEM | Jeol JSM 5500 LV SEM |

| Electron emitter type | FEG (Field Emission Gun) | FEG (Field Emission Gun) | FEG (Field Emission Gun) | Tungsten filament |

| Vacuum modes | High vacuum (>2*10mbar) and Low vacuum (0.1-1.9 mbar) | High vacuum (>2*10mbar) | High vacuum and Low vacuum | |

| Detectors | High and Low vacuum detectors of SE and BSE electrons, HiVac Inlens SE detector and high resolution Low vacuum detector | SE, Inlens SE and BSE detectors | High vacuum SE and BSE detector | |

| Substrate size | Up to 6" wafer with full view | Up to 6" wafer with 4" full view | Up to 4" wafer with full view | |

| Additional equipment | Kleindiek micromanipulator with Capres 4 point probe | |||

| Best obtainable lateral resolution (strongly dependent on user skills and sample type) | Down to 1-2 nm (Limiting factor: Beam) | Down to 10 nm (Limiting factor: Vibrations) | Down to 20-30 nm (Limiting factor: Vibrations) | |

| General availability | Good | Poor | Excellent | |

| Ease of use | A sophisticated user interface with many features and many different detectors: Complicated | A simple user interface with joystick and a limited number of detectors: Relatively simple | A simple user interface with joystick with one detector: Very simple | |

| User level access | Only experienced SEM users, masters/Ph.D students with special needs will be trained | Any cleanroom user | Any cleanroom user | |

| Best usage | High resolution imaging of any sample | High resolution imaging of any non-polymer sample | Fast in-process imaging | |

| EDX analysis | Oxford Inca system | Röntec system | Not available |