Specific Process Knowledge/Back-end processing/Disco Saw: Difference between revisions

No edit summary |

mNo edit summary |

||

| Line 1: | Line 1: | ||

'''Feedback to this page''': '''[mailto:danchipsupport@danchip.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.danchip.dtu.dk/index.php?title=Specific_Process_Knowledge/Back-end_processing/Disco_Saw click here]''' | '''Feedback to this page''': '''[mailto:danchipsupport@danchip.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.danchip.dtu.dk/index.php?title=Specific_Process_Knowledge/Back-end_processing/Disco_Saw click here]''' | ||

==Disco Automatic dicing saw, model DAD321 | ==Disco Automatic dicing saw, model DAD321 and DAD3241== | ||

DTU nanolab has 2 saw available for dicing substrates into separate chips. Both tools offer versatile processing capabilities, high precision and reliability. | |||

The dicers at DTU Nanolab is placed in room 157 on the first floor in bldg. 346. Please notice that this is not | The dicers at DTU Nanolab is placed in room 157 on the first floor in bldg. 346. Please notice that this room is not under filter. Generally speaking the dicing process is very dirty, and you should expect particle contaminants on your device. | ||

[[File:IMG_20230228_112922.jpg|center|thumb||Dicers positioned on 1. floor bldg 346 room 157]] | |||

<div style="clear: both"></div> | |||

[[ | In general it is ''not allowed'' to bring back your samples into the Cleanroom. You need approval from DTU Nanolab staff to do this, follow the instructions [[Specific Process Knowledge/Wafer cleaning/Bring samples into cleanroom|here]] to apply for approval. Your samples have to be thoroughly cleaned before entry, at a minimum a triton ultrasonic clean followed by a piranha clean. You will only be allowed to use a limited number of tools for the processing after dicing. | ||

Please consider your layout of dies on your wafer. The dicer can only cut straight lines across the | |||

===Dicing layout=== | |||

Please consider your layout of dies on your wafer. The dicer can only cut straight lines across the entire wafer. | |||

Please see the illustrations for a good and a bad design. | Please see the illustrations for a good and a bad design. | ||

| Line 41: | Line 40: | ||

*[[Specific Process Knowledge/Back-end processing/Disco Saw#Comparing dicing parameters for different materials |Comparing dicing parameters for different materials]] | *[[Specific Process Knowledge/Back-end processing/Disco Saw#Comparing dicing parameters for different materials |Comparing dicing parameters for different materials]] | ||

*[[Specific Process Knowledge/Back-end processing/Disco Saw#Images of diced samples |Images of diced samples]] | <!--*[[Specific Process Knowledge/Back-end processing/Disco Saw#Images of diced samples |Images of diced samples]] | ||

*Dicing work sheet: [[Media:Dicing Work Sheet v2.docx |Dicing Work Sheet v2.docx]] Fill out before requesting dicing. | *Dicing work sheet: [[Media:Dicing Work Sheet v2.docx |Dicing Work Sheet v2.docx]] Fill out before requesting dicing. | ||

Revision as of 11:07, 29 January 2026

Feedback to this page: click here

Disco Automatic dicing saw, model DAD321 and DAD3241

DTU nanolab has 2 saw available for dicing substrates into separate chips. Both tools offer versatile processing capabilities, high precision and reliability.

The dicers at DTU Nanolab is placed in room 157 on the first floor in bldg. 346. Please notice that this room is not under filter. Generally speaking the dicing process is very dirty, and you should expect particle contaminants on your device.

In general it is not allowed to bring back your samples into the Cleanroom. You need approval from DTU Nanolab staff to do this, follow the instructions here to apply for approval. Your samples have to be thoroughly cleaned before entry, at a minimum a triton ultrasonic clean followed by a piranha clean. You will only be allowed to use a limited number of tools for the processing after dicing.

Dicing layout

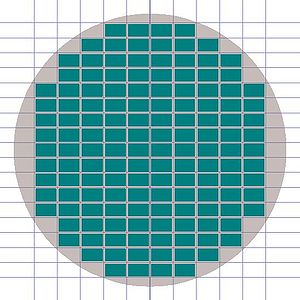

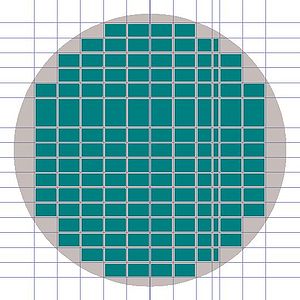

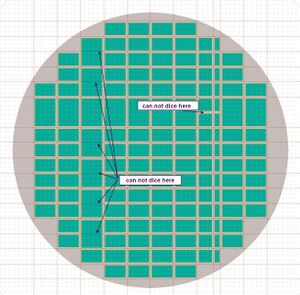

Please consider your layout of dies on your wafer. The dicer can only cut straight lines across the entire wafer. Please see the illustrations for a good and a bad design.

| GOOD design - simple | GOOD design - complex | BAD design | |

|

|

|

|

| GOOD design - simple | GOOD design - complex | BAD design | |

| drawings by Jesper Hanberg, DTU Nanolab |

Process information

- The user manual, user APV, technical information and contact information can be found in LabManager:

Available blades

THIS CHAPTER IS WORK IN PROGRESS

DISCO provides a wide selection of dicing blades optimized for different materials. There catalogue can be accessed online here DTU Nanolab provides 2 different blades for 2 main use-cases