Specific Process Knowledge/Etch/ICP Metal Etcher/Chromium: Difference between revisions

| Line 62: | Line 62: | ||

* [[:File:report_summer2022 Anders Simonsen bghe edits.pdf | Cr etch development report summery by Anders Simonesen, summer of 2022 ]] | * [[:File:report_summer2022 Anders Simonsen bghe edits.pdf | Cr etch development report summery by Anders Simonesen, summer of 2022 ]] | ||

* [[/Cr etch data from AS |Here are the raw test data and SEM images from Anders Simonsen]] | * [[/Cr etch data from AS |Here are the raw test data and SEM images from Anders Simonsen]] | ||

Preferer result: | |||

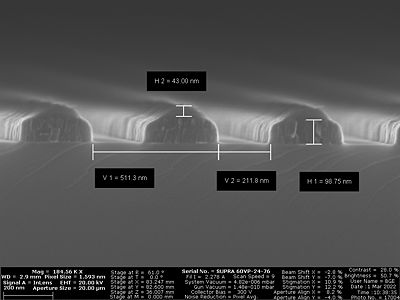

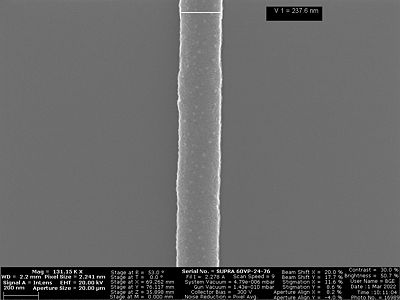

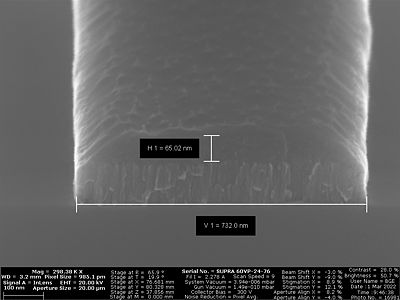

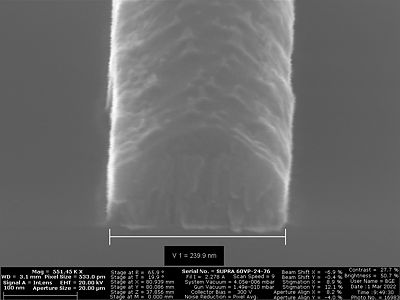

The SEM images where done after both the Cr etch and the silicon nitride etch in the AOE using the recipe "?". The important thing was to see how well the Cr works for masking the nitride given vertical and smooth sidewalls in the nitride. | |||

{| class="wikitable" | |||

! Recipe !! Pressure [mTorr] !! Coil power [W] !! Platen power [W] !! Total Flow Cl2+O2 [sccm] !! O2% !! Temp !! !! Time [s] !! CSAR etch rate [nm/min] !! CSAR rate w bond !! !! Etch rate [nm/min] !! Selectivity !! !! coil load !! coil tune !! plat load !! plat tune !! Comment | |||

|- | |||

! test13/laqs | |||

| 10 || 300 || 15 || 30 || 23.33 || 20 || || 28 || 100.71 || || || 42.86 || 0.43 || || || || || || This recipe was chosen over no. 12 because it did not need a large over etch of the Cr (no foot). | |||

|- | |||

|} | |||

==Chromium etch in ICP metal on a thick glass substrate== | ==Chromium etch in ICP metal on a thick glass substrate== | ||

Revision as of 11:04, 29 September 2022

Feedback to this page: click here

Chromium etch in ICP metal - small substrate using carrier

The Chromium etch was carried out on the following substrate stack: 2" Si wafer with Cr laying in a 6" Si wafer with a 4" recess. The area outside the recess was covered by AZ resist. The work was carried out be Erol Zekovic @Nanotech and BGHE@nanolab

| Parameter | Cr etch |

|---|---|

| Cl2 (sccm) | 65 |

| O2 (sccm) | 15 |

| Pressure (mTorr) | 15 |

| Coil power (W) | 300 |

| Platen power (W) | 15 |

| Temperature (oC) | 50 |

| Spacers (mm) | 100 |

| Etch rate (nm/min) | ~32 (Date: 2014-08-13) |

| Zep520A resist selectivity | NA |

| Comment | Was masked by capton tape |

- Etching lines in 100nm Cr with the Cr etch for 3 min with 300 nm DUV resist BGHE@Nanolab Feb 2022

Chromium etch of hardmask for silicon nitride etching by Anders Simonsen@nbi.ku

Added by bghe@Nanolab

Anders has done some work on optimizing the Cr etch for at 20-40 nm thick Cr that was to be used as masking for a silicon nitride etch. The Cr etch was carriered out on the ICP metal and the silicon nitride etch was done on the AOE. You can see his results in this summery that he has made:

- Cr etch development report summery by Anders Simonesen, summer of 2022

- Here are the raw test data and SEM images from Anders Simonsen

Preferer result:

The SEM images where done after both the Cr etch and the silicon nitride etch in the AOE using the recipe "?". The important thing was to see how well the Cr works for masking the nitride given vertical and smooth sidewalls in the nitride.

| Recipe | Pressure [mTorr] | Coil power [W] | Platen power [W] | Total Flow Cl2+O2 [sccm] | O2% | Temp | Time [s] | CSAR etch rate [nm/min] | CSAR rate w bond | Etch rate [nm/min] | Selectivity | coil load | coil tune | plat load | plat tune | Comment | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| test13/laqs | 10 | 300 | 15 | 30 | 23.33 | 20 | 28 | 100.71 | 42.86 | 0.43 | This recipe was chosen over no. 12 because it did not need a large over etch of the Cr (no foot). |

Chromium etch in ICP metal on a thick glass substrate

The Chromium etch has ONLY been carried out on the following substrate stack: The Chromium is sputter deposited onto a 2" quartz wafer and patterned by e-beam with Zep520A resist. This 2" QZ wafer is bonded with crystal bond to a 65mmx65mm quartz plate with the thickness: 6.35mm. This QZ plate is bonded to a Si wafer.

| Parameter | Cr etch |

|---|---|

| Cl2 (sccm) | 65 |

| O2 (sccm) | 15 |

| Pressure (mTorr) | 15 |

| Coil power (W) | 300 |

| Platen power (W) | 15 |

| Temperature (oC) | 50 (no back side cooling) |

| Spacers (mm) | 100 |

| Etch rate (nm/min) | ~14 |

| Zep520A resist selectivity | ~0.9 |

| Comment | . |