Specific Process Knowledge/Etch/III-V ICP/InP-InGaAsP-InGaAs: Difference between revisions

No edit summary |

|||

| Line 52: | Line 52: | ||

|} | |} | ||

<gallery> | |||

Image:Picture1.jpg|ghjhg | |||

Image:Picture2.jpg | |||

Image:Picture3.jpg | |||

Image:Picture4.jpg | |||

Image:Picture5.jpg | |||

Image:Picture6.jpg | |||

Image:Picture7.jpg | |||

Image:Picture8.jpg | |||

Image:Picture9.jpg | |||

</gallery> | |||

=== InP etch with Cl2/CH4/Ar 2013=== | === InP etch with Cl2/CH4/Ar 2013=== | ||

Revision as of 14:31, 21 October 2019

Feedback to this page: click here

InP etch with HBr chemistry

Work done by Aurimas Sakanas @Fotonik.dtu 2019

| Recipe | ? |

| HBr flow | 10 sccm |

| CH4 flow | 5 sccm |

| Ar flow | 2 sccm |

| Platen power | 50 W |

| Coil power | 600 W |

| Pressure | 5 mTorr |

| Platen chiller temperature | 180 oC |

| Comment | Sample crystal bonded (Crystalbond 509, clear color) to Si carrier |

| Results | |

| Etch rate |

250-350 nm/min (2" wafer) |

| Sidewall angle |

85-87 o (bottom) |

| Selectivity (InP:HSQ) | 15:1 (2"), 20:1 |

-

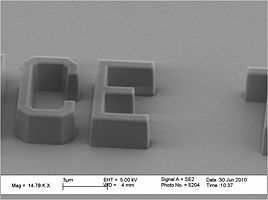

ghjhg

InP etch with Cl2/CH4/Ar 2013

Work done by Matthew Haines in 2013

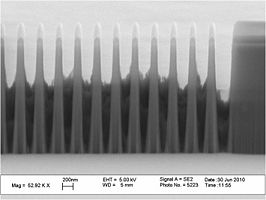

InP/InGaAsP/InGaAs etch 2011

Unselective etch for large sized features and small aspect ratios by David Larsson, DTU Photonics, 2011

| Recipe | InP Etch 1/InP Precond 1 |

| Cl2 flow | 20 sccm |

| N2 flow | 40 sccm |

| Ar flow | 10 sccm |

| Platen power | 100 W |

| Coil power | 500 W |

| Pressure | 2 mTorr |

| Platen chiller temperature | 180 oC |

| Comment | Use SiO2 carrier (not Si) (Kabi/Bghe June 2018) |

| Results (InP Etch 1) | |

| Etch rate | 500-600 nm/min |

| Sidewall angle | 86-87 o |

| Selectivity (InP:SiO2, InP:HSQ) | 50:1 |

- Result of InP etching. David Larsson, DTU Photonics, 2011

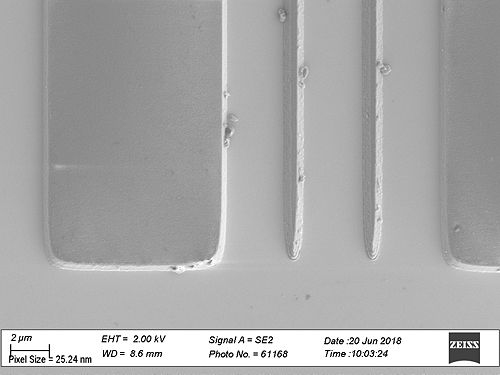

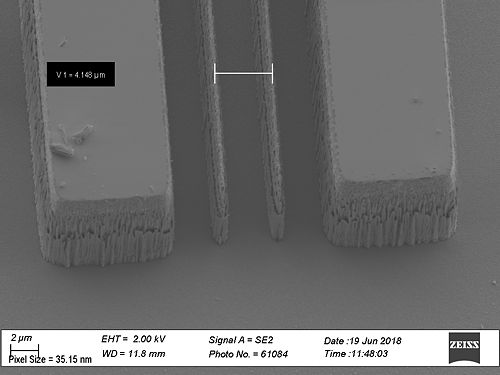

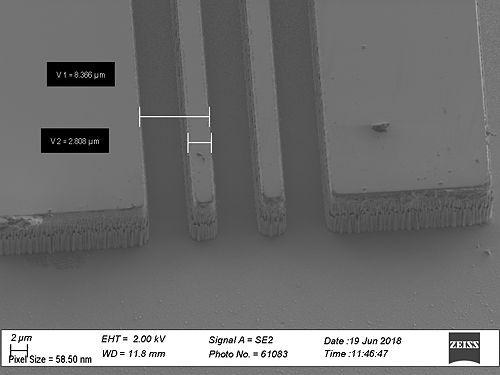

InP etching June 2018

Done by Kabi and Bghe @danchip

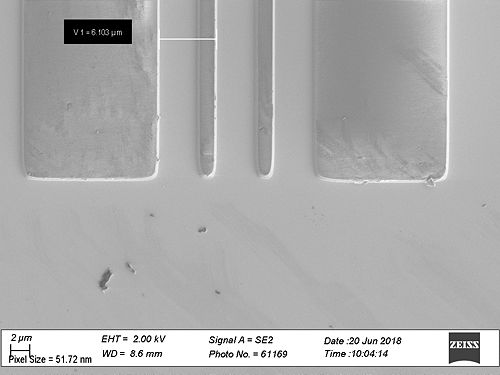

Sample pattern before etching

- Oxide mask before etching.

-

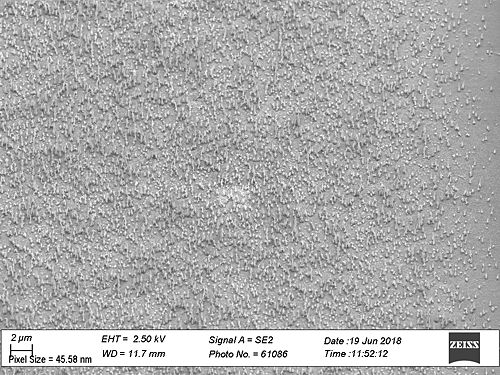

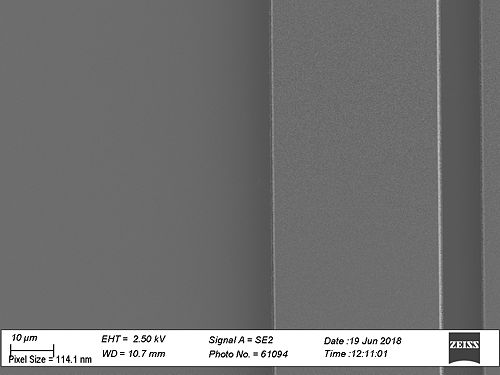

Top view of the SiO2 mask before etching

-

Top view of the SiO2 mask before etching

Etching of an InP piece on Si carrier

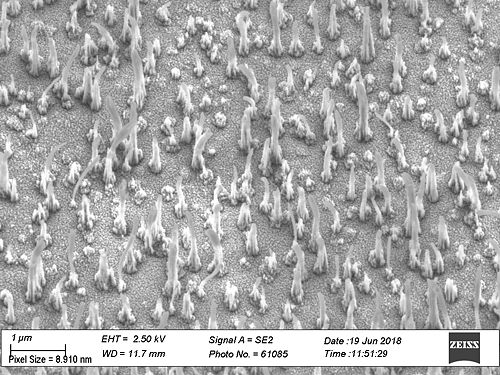

InP piece patterned with SiO2. The piece was etched on top of a Si wafer without bonding. The recipe "InP etch" was used. The roughness looks high in the bottom of the etched areas, especially in the large open areas.

- Result of InP etching.

-

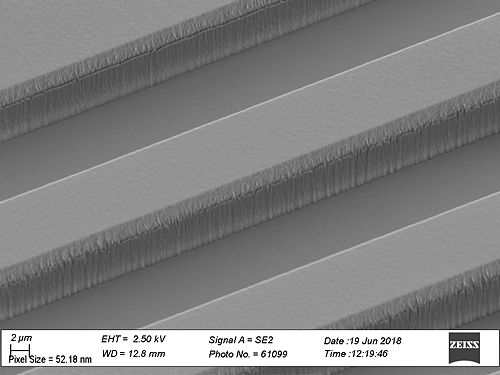

low roughness in narrow trenched

-

low roughness in narrow trenched

-

A little higher roughnedd is larger trences

-

Much larger roughness in open areas

-

Zoom in on the large roughness

-

closed look at the large roughness in the open areas.

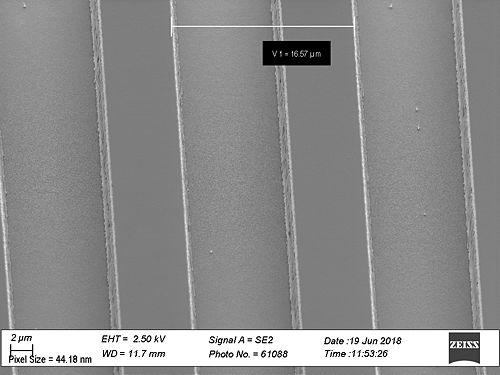

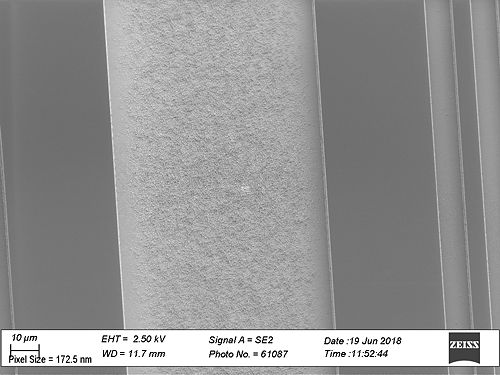

Etching of an InP piece on SiO2 carrier

InP piece patterned with SiO2. The piece was etched on top of a Si wafer coated with SiO2 without bonding. The recipe "InP etch" was used. The roughness looks low in the bottom of the etched areas, even in the large open areas.

- Result of InP etching.

-

Top view: oxide is gone on the narrow lines, low roughness in the trenches.

-

Top view: low roughness in the trenches.

-

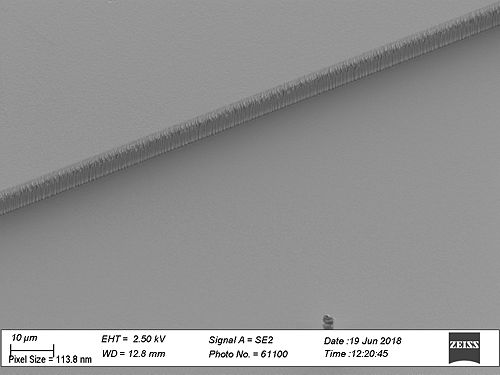

30 dg view: low roughness in the trenches

-

30 dg view: low roughness in the trenches

-

Top view: low roughness in trench and in the large area

Changing the Cl2/N2 ratio

- Result of changing the Cl2/N2 ratio.

-

Sample S0: Top view of the oxide mask before etching. It is the TRAVKA50 mask, but it is clear that the CD reduction is about the 1-1.5 µm of the lines.

-

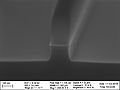

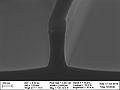

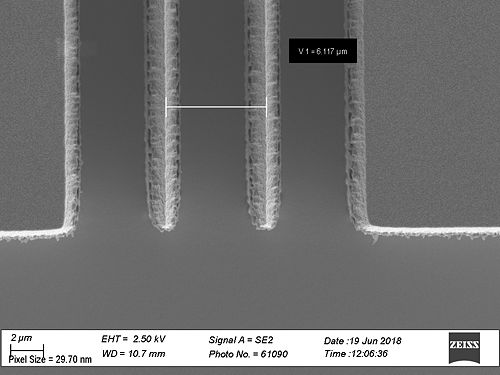

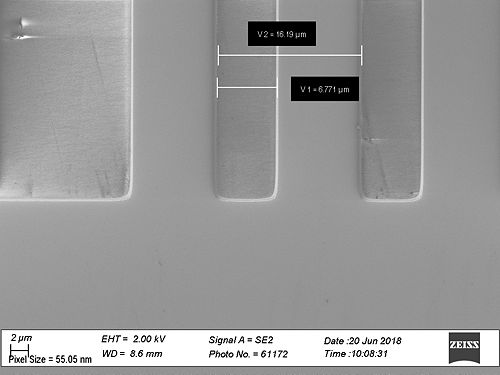

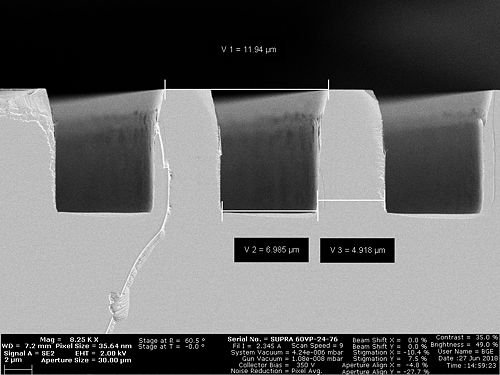

Sample S4: Profile view. The recipe InP etch has been used.

The sample has been run on a SiO2 carrier wafer.

There is not much CD change compared to the oxide mask before the etch.

It seems like the SiO2 mask is gone and the sidewall angle from the mask has been transferred into the sample.

The sidewall profile is quit vertical in the lower part.

Etch time 15 min

Etch depth in large open areas: 9.19µm -

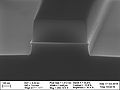

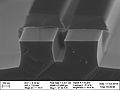

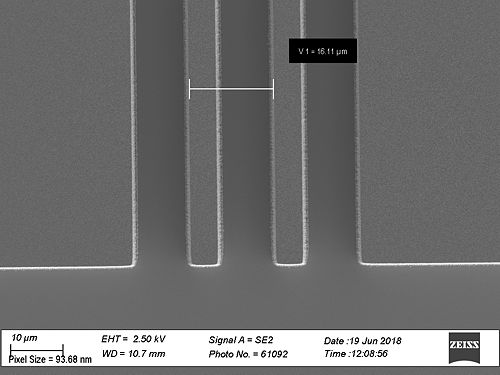

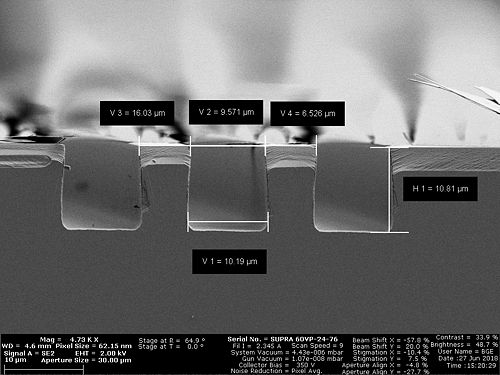

Sample S5: Profile view. The recipe InP etch has been used but with modified Cl2 and N2 flows: N2=30 sccm Cl2=30 sccm.

The sample has been run on a SiO2 carrier wafer.

There is not much CD change compared to the oxide mask before the etch.

It seems like the SiO2 mask is gone.

The sidewall profile is overcutting probably due to too little passivation.

Etch time 10 min

Etch depth in large open areas: 11.82µm -

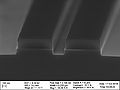

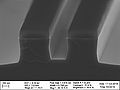

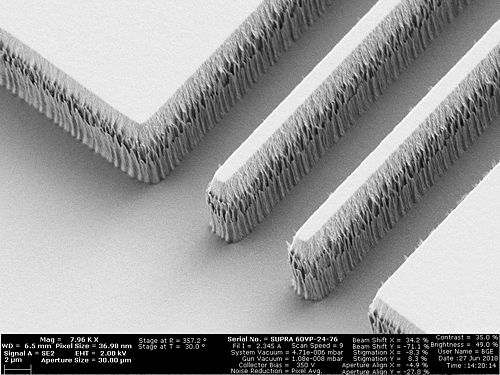

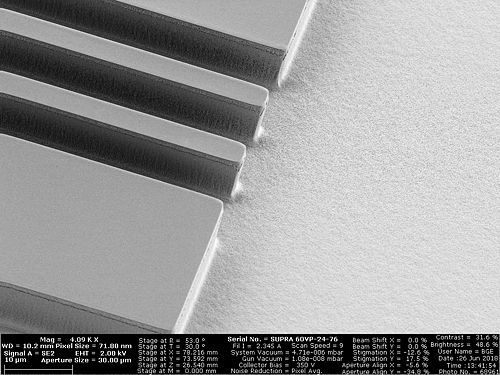

Sample S4: The sidewall roughness on the sample S4 is quit high

-

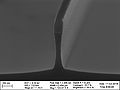

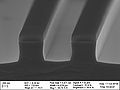

Sample S5: The sidewall roughness on the sample S5 is quit low.