Specific Process Knowledge/Characterization/Lifetime scanner MDPmap: Difference between revisions

| Line 17: | Line 17: | ||

only by the diffusion length of the charge carriers. | only by the diffusion length of the charge carriers. | ||

'''The user manual | '''The user manual, the APV and contact information can be found in LabManager:''' | ||

[http://labmanager.dtu.dk/function.php?module=Machine&view=view&mach=338 Lifetime scanner MPDmap info page in LabManager], | [http://labmanager.dtu.dk/function.php?module=Machine&view=view&mach=338 Lifetime scanner MPDmap info page in LabManager], | ||

Revision as of 10:20, 19 April 2016

THIS PAGE IS UNDER CONSTRUCTION

Feedback to this page: click here

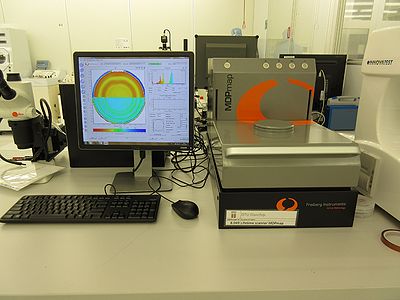

Microwave Detected Photoconductivity (MDP)

Topographic visualisation of electrically active defects or materiel properties at almost any production stage, allows for process optimization and performance prediction of devices.

MDP is a contact less, non destructive measurement technology for the electrical characterization of a large variety of semiconductors. The mapping and visualization of so far not detectable defects was achieved by improving the sensitivity of a microwave detection system by several orders of magnitude. Electrical properties such as lifetime, τ, mobility, μ, and diffusion length, L, can be measured also at very low injection levels with a spatial resolution limited only by the diffusion length of the charge carriers.

The user manual, the APV and contact information can be found in LabManager:

Lifetime scanner MPDmap info page in LabManager,

Performance information

| Equipment | Lifetime scanner MDPmap | |

|---|---|---|

| Purpose |

| |

| Location |

| |

| Instrument specifics | Detector |

|

| Laser |

| |

| Substrates | Size |

|

| Allowed materials |

| |