Specific Process Knowledge/Thin film deposition/PECVD/Doping: Difference between revisions

Appearance

| Line 12: | Line 12: | ||

|- | |- | ||

|Recipe name | |Recipe name | ||

| | |SiH<sub>4</sub> flow [sccm] | ||

|N<sub>2</sub>O flow [sccm] | |N<sub>2</sub>O flow [sccm] | ||

|N2 flow [sccm] | |N2 flow [sccm] | ||

| | |B<sub>2</sub>H<sub>6</sub> flow [sccm] | ||

| | |PH<sub>3</sub> flow [sccm] | ||

|Pressure [mTorr] | |Pressure [mTorr] | ||

|Power [W] | |Power [W] | ||

| Line 32: | Line 32: | ||

|} | |} | ||

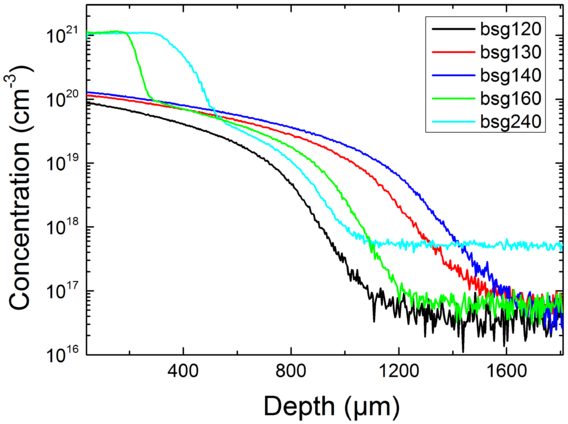

5 tests were made where only the | 5 tests were made where only the B<sub>2</sub>H<sub>6</sub> flow was changed for each deposition (120sccm,130sccm,140sccm,160sccm,240sccm). All deposition times were 2 min (resulting in 440 nm Oxide). | ||

The wafers were annealed in Anneal Oxide Furnace (C1) at 1000°C for 85 min to drive in the boron and the oxide was subsequently etched in BHF. The wafers were then | The wafers were annealed in Anneal Oxide Furnace (C1) at 1000°C for 85 min to drive in the boron and the oxide was subsequently etched in BHF. The wafers were then analyzed by SIMS and the results are shown in the figure below: | ||

Revision as of 12:34, 1 December 2015

Feedback to this page: click here

THIS PAGE IS UNDER CONSTRUCTION

Boron-doping by use of BSG glass deposited in PECVD

Recipe

| Recipe name | SiH4 flow [sccm] | N2O flow [sccm] | N2 flow [sccm] | B2H6 flow [sccm] | PH3 flow [sccm] | Pressure [mTorr] | Power [W] | Description |

| 1PBSG | 17 | 1600 | 0 | 120, 130, 140, 160, 240 | 0 | 400 | 380 | BPSG glass for drive in boron in Silicon |

5 tests were made where only the B2H6 flow was changed for each deposition (120sccm,130sccm,140sccm,160sccm,240sccm). All deposition times were 2 min (resulting in 440 nm Oxide). The wafers were annealed in Anneal Oxide Furnace (C1) at 1000°C for 85 min to drive in the boron and the oxide was subsequently etched in BHF. The wafers were then analyzed by SIMS and the results are shown in the figure below: